20 Jahre Erfahrung | 1000+ Markenpartner | Vollständige Anpassung

Wir haben 20 Jahre Branchenerfahrung, haben mit über 1.000 Marken zusammengearbeitet und unterstützen alle Anpassungsbedürfnisse.

Technical Specifications

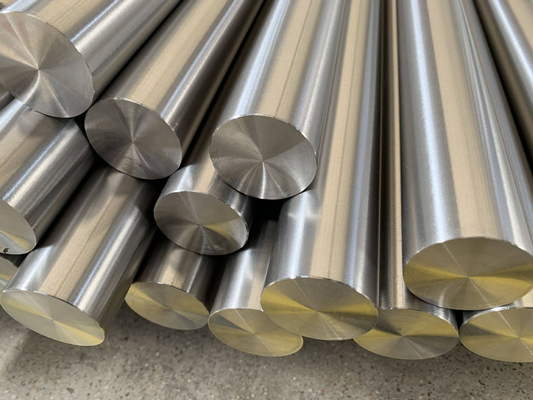

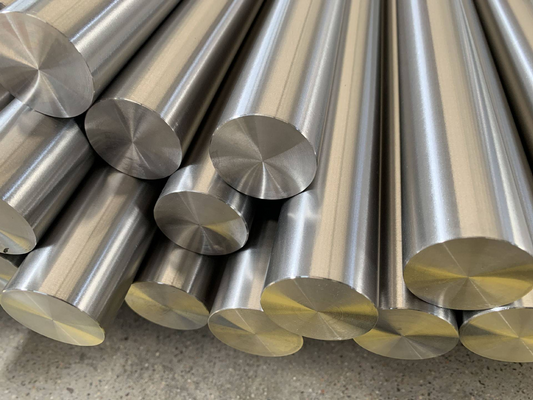

Product Overview

Metallurgische Eigenschaften

UNS N10665 ist eine festigkeitssteigernde Nickel-Molybdän-Legierung mit außergewöhnlicher Korrosionsbeständigkeit in reduzierenden Umgebungen. Der hohe Molybdängehalt (26-30%) bietet hervorragenden Widerstand gegen Salzsäure, Schwefelsäure und andere reduzierende Medien. Die Legierung behält ihre Korrosionsbeständigkeit bei Temperaturen von bis zu 650°C und zeigt eine ausgezeichnete thermische Stabilität.

Wärmebehandlung und Verarbeitung

MetalZenith verwendet Lösungsglühen bei 1065-1120°C, gefolgt von schneller Abkühlung, um optimale Eigenschaften zu erreichen. Die Legierung kann nicht durch Ausscheidungshärtung gehärtet werden, sondern gewinnt ihre Festigkeit durch Kaltverformung. Unsere kontrollierte Atmosphäre bei der Wärmebehandlung verhindert Oxidation und erhält die Oberflächenqualität. Das Warmarbeiten erfolgt zwischen 1010-1175°C mit sorgfältiger Temperaturkontrolle, um Rissbildung zu vermeiden.

Exzellenz im Herstellungsprozess

Unser Herstellungsprozess beginnt mit Vakuum-Induktionsschmelzen unter Verwendung von hochreinen Rohmaterialien, gefolgt von Vakuum-Arc-Umschmelzen zur Verbesserung der Sauberkeit. Die Blöcke durchlaufen eine Homogenisierungshitze-Behandlung vor den Warmbearbeitungsoperationen. Die fortschrittlichen Walz- und Schmiedeverfahren von MetalZenith gewährleisten eine gleichmäßige Mikrostruktur und mechanische Eigenschaften über den gesamten Querschnitt des Produkts.

Qualitätsstandards und Prüfung

Alle UNS N10665 Produkte unterliegen umfassenden Tests, einschließlich chemischer Analyse durch optische Emissionsspektroskopie, mechanischer Prüfung gemäß ASTM-Standards, Ultraschalluntersuchung und speziellen Korrosionstests. MetalZenith gewährleistet vollständige Rückverfolgbarkeit von Rohmaterialien bis zu fertigen Produkten, mit detaillierter Dokumentation einschließlich Werksprüfzertifikaten, Wärmebehandlungsprotokollen und Maßprüfberichten. Unser Qualitätssystem entspricht ASTM B333, NACE MR0175 und anderen relevanten internationalen Standards.

🧪 Chemical Composition

| Element | Zusammensetzung (%) |

|---|---|

| Nickel (Ni) | Rest (62.0 min) |

| Molybdän (Mo) | 26.0 - 30.0 |

| Chrom (Cr) | ≤ 1.0 |

| Eisen (Fe) | ≤ 2.0 |

| Kobalt (Co) | ≤ 1.0 |

| Kohlenstoff (C) | ≤ 0.02 |

| Mangan (Mn) | ≤ 1.0 |

| Silizium (Si) | ≤ 0.10 |

| Phosphor (P) | ≤ 0.04 |

| Schwefel (S) | ≤ 0.03 |

⚙️ Mechanical Properties

| Eigenschaft | Wert |

|---|---|

| Zugfestigkeit (Ultimativ) | 760 - 1035 MPa |

| Streckgrenze (0,2% Offset) | ≥ 350 MPa |

| Dehnung in 50mm | ≥ 40% |

| Härte (Brinell) | ≤ 230 HB |

| Härte (Rockwell B) | ≤ 100 HRB |

| Youngs Modul | 230 GPa |

| Schermodul | 85 GPa |

| Poisson-Zahl | 0.35 |

| Schlagenergie (Charpy V-Kerbe) | ≥ 200 J |

🔬 Physical Properties

| Eigenschaft | Wert |

|---|---|

| Dichte | 9.24 g/cm³ |

| Schmelzpunkt | 1370 - 1400°C |

| Wärmeleitfähigkeit (100°C) | 11.1 W/m·K |

| Wärmeleitfähigkeit (500°C) | 18.4 W/m·K |

| Wärmeausdehnung (20-100°C) | 11.1×10-6/K |

| Wärmeausdehnung (20-500°C) | 12.4×10-6/K |

| Spezifische Wärme (20°C) | 377 J/kg·K |

| Elektrische Widerstandsfähigkeit (20°C) | 1.31 µΩ·m |

| Magnetische Permeabilität | 1.002 (paramagnetisch) |

| Curie-Temperatur | Nicht-magnetisch |

📏 Product Specifications

| Spezifikation | Verfügbare Optionen |

|---|---|

| Produktformen | Runde Stangen, flache Stangen, Bleche, Platten, Rohre, Rohre, Schmiedeteile, Draht |

| Durchmesser der runden Stange | 6mm - 300mm |

| Abmessungen der flachen Stange | 10×3mm - 200×50mm |

| Blechdicke | 0.5mm - 6mm |

| Plattendicke | 6mm - 100mm |

| Äußerdurchmesser des Rohrs | 6mm - 219mm |

| Standards | ASTM B333, ASTM B564, ASTM B619, ASTM B622, ASTM B626, ASTM B574 |

| Oberflächenfinish | Warmgewalzt, kaltgewalzt, geglüht, entpickelt, poliert |

| Maßtoleranz | ±0.1mm bis ±0.5mm (je nach Form und Größe) |

| Länge | Bis zu 12 Meter (maßgeschneiderte Längen verfügbar) |

Lassen Sie uns Erfolg für Ihr Projekt schaffen

Professionelles Team, Premium-Produkte, Vollständiger Service - Ihr Projekterfolg ist unsere Mission

Our Advantages in Processing UNS N10665

Fortgeschrittene Vakuum-Schmelztechnologie

MetalZenith nutzt modernste Vakuum-Induktionsschmelzen (VIM) und Vakuum-Arc-Umschmelzen (VAR), um UNS N10665 mit überlegener chemischer Homogenität, minimalen Einschlüssen und außergewöhnlicher metallurgischer Qualität herzustellen. Unsere kontrollierte Atmosphärenverarbeitung gewährleistet optimale Reinheit und Leistungseigenschaften.

Umfassende Qualitätskontrollsysteme

Unser integriertes Qualitätsmanagementsystem umfasst fortschrittliche spektroskopische Analysen, mechanische Prüf laboratories und spezialisierte Korrosionsprüf einrichtungen. Jede Charge unterliegt einer strengen Inspektion mit vollständiger Rückverfolgbarkeitsdokumentation, die konsistente Materialeigenschaften und die Einhaltung internationaler Standards gewährleistet.

Benutzerdefinierte Verarbeitung und globale Versorgung

MetalZenith bietet umfangreiche Anpassungsmöglichkeiten, einschließlich Präzisionsbearbeitung, Optimierung der Wärmebehandlung und spezialisierte Oberflächenbehandlungen. Unser globales Vertriebsnetz und strategisches Bestandsmanagement gewährleisten eine zuverlässige Leistung der Lieferkette mit flexiblen Lieferoptionen weltweit.

IHR VERTRAUENwürdiger STAHL

HERSTELLUNGSPARTNER

Schnellanfrage

Branchen, die wir bedienen

Professionelle Stahl-Lösungen in wichtigen Branchen

Qualifikationen & Zertifizierungen