20 Jahre Erfahrung | 1000+ Markenpartner | Vollständige Anpassung

Wir haben 20 Jahre Branchenerfahrung, haben mit über 1.000 Marken zusammengearbeitet und unterstützen alle Anpassungsbedürfnisse.

Technical Specifications

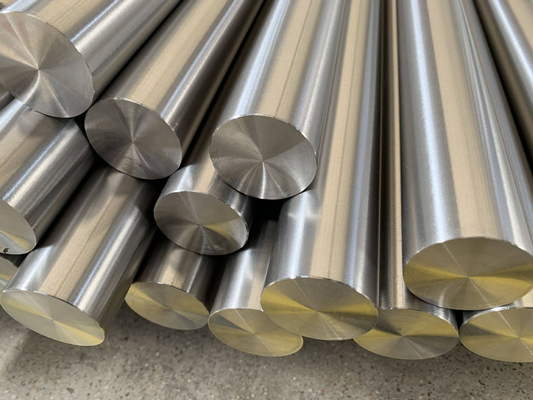

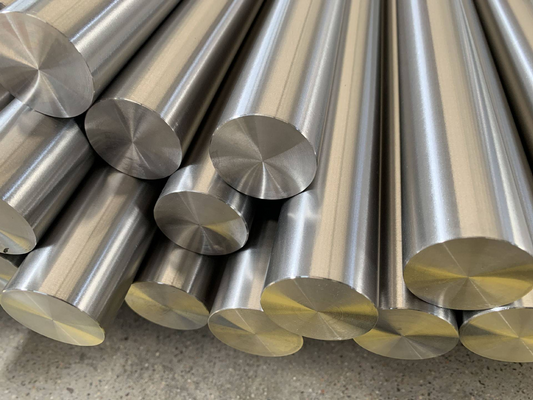

Product Overview

Metallurgische Eigenschaften

GH3625 ist eine festigkeitssteigernde Nickel-Chrom-Molybdän-Superlegierung mit außergewöhnlicher Beständigkeit gegen Oxidation und Korrosion. Die austenitische Struktur der Legierung bleibt über einen breiten Temperaturbereich stabil, während Niob-Zusätze eine Ausscheidungshärtung durch die Bildung von Gamma-Doppel-Prime (γ'') und Delta (δ) Phasen ermöglichen. Der hohe Molybdän- und Chromgehalt gewährleistet eine überlegene Beständigkeit gegen Lochfraß, Spaltkorrosion und Spannungsrisskorrosion.

Wärmebehandlungsprozess

MetalZenith verwendet präzise Wärmebehandlungsprotokolle für GH3625, einschließlich Lösungsglühen bei 1150-1177°C, gefolgt von schnellem Abkühlen, um optimale mechanische Eigenschaften zu erreichen. Alterungshärtungsbehandlungen bei 650-750°C können angewendet werden, um die Festigkeit durch kontrollierte Ausscheidung von härtenden Phasen zu erhöhen. Unsere kontrollierten Atmosphärenöfen gewährleisten konsistente Ergebnisse und verhindern Oxidation während der Verarbeitung.

Herstellungsprozess

Unsere GH3625-Produktion beginnt mit dem Vakuum-Induktionsschmelzen (VIM) von hochreinen Rohmaterialien, gefolgt von Vakuum-Arc-Umschmelzen (VAR) oder Elektroschlacke-Umschmelzen (ESR), um überlegene Sauberkeit und Homogenität zu erreichen. Warmbearbeitungsoperationen, einschließlich Schmieden, Walzen und Extrusion, werden innerhalb sorgfältig kontrollierter Temperaturbereiche durchgeführt, um die Kornstruktur und die mechanischen Eigenschaften zu optimieren. Kaltbearbeitungs- und Zwischenanlaufzyklen werden für eine präzise Maßkontrolle eingesetzt.

Qualitätsstandards & Prüfung

MetalZenith hält umfassende Qualitätskontrollen während der GH3625-Produktion aufrecht, einschließlich chemischer Analysen durch optische Emissionsspektroskopie (OES) und Röntgenfluoreszenz (XRF), mechanischer Prüfungen gemäß ASTM-Standards, Ultraschallprüfungen auf innere Festigkeit und mikrostrukturelle Untersuchungen. Alle Produkte entsprechen den Luftfahrtvorschriften, einschließlich AMS 5599, und den nuklearen Standards wie ASME Abschnitt III. Vollständige Materialverfolgbarkeit und Dokumentation werden mit jeder Lieferung bereitgestellt.

🧪 Chemical Composition

| Element | Zusammensetzung (%) |

|---|---|

| Nickel (Ni) | 58.0 min |

| Chrom (Cr) | 20.0-23.0 |

| Molybdän (Mo) | 8.0-10.0 |

| Niob + Tantal (Nb+Ta) | 3.15-4.15 |

| Eisen (Fe) | ≤ 5.0 |

| Kohlenstoff (C) | ≤ 0.10 |

| Mangan (Mn) | ≤ 0.50 |

| Silizium (Si) | ≤ 0.50 |

| Phosphor (P) | ≤ 0.015 |

| Schwefel (S) | ≤ 0.015 |

| Aluminium (Al) | ≤ 0.40 |

| Titan (Ti) | ≤ 0.40 |

| Kobalt (Co) | ≤ 1.0 |

⚙️ Mechanical Properties

| Eigenschaft | Wert | Testbedingung |

|---|---|---|

| Zugfestigkeit | ≥ 827 MPa | Raumtemperatur |

| Streckgrenze (0,2% Offset) | ≥ 414 MPa | Raumtemperatur |

| Dehnung | ≥ 30% | Raumtemperatur |

| Flächenreduzierung | ≥ 50% | Raumtemperatur |

| Härte (HB) | 240-290 | Geglühter Zustand |

| Härte (HRC) | 25-32 | Geglühter Zustand |

| Schlagenergie (Charpy V-Kerbe) | ≥ 120 J | Raumtemperatur |

| Ermüdungsfestigkeit (107 Zyklen) | 380 MPa | Raumtemperatur |

| Youngs Modul | 208 GPa | Raumtemperatur |

| Schubmodul | 81 GPa | Raumtemperatur |

| Poisson-Zahl | 0.31 | Raumtemperatur |

🔬 Physical Properties

| Eigenschaft | Wert | Temperatur |

|---|---|---|

| Dichte | 8.44 g/cm³ | 20°C |

| Schmelzpunkt | 1290-1350°C | - |

| Wärmeleitfähigkeit | 9.8 W/m·K | 20°C |

| Wärmeleitfähigkeit | 19.4 W/m·K | 540°C |

| Spezifische Wärmekapazität | 410 J/kg·K | 20°C |

| Wärmeausdehnungskoeffizient | 12.8×10-6/K | 20-100°C |

| Wärmeausdehnungskoeffizient | 14.6×10-6/K | 20-650°C |

| Elektrische Widerstandsfähigkeit | 1.29 µΩ·m | 20°C |

| Magnetische Permeabilität | 1.0008 | Raumtemperatur |

| Curie-Temperatur | -196°C | - |

📏 Product Specifications

| Spezifikation | Verfügbare Optionen |

|---|---|

| Produktformen | Runde Stangen, quadratische Stangen, Flachstangen, Platten, Bleche, Streifen, Rohre, Rohre, Schmiedeteile, Draht |

| Durchmesser der Rundstange | 6mm - 300mm |

| Plattendicke | 3mm - 100mm |

| Blechdicke | 0.5mm - 6mm |

| Äußerdurchmesser des Rohrs | 6mm - 219mm |

| Drahtdurchmesser | 0.1mm - 10mm |

| Länge | Bis zu 12 Meter (maßgeschneiderte Längen verfügbar) |

| Oberflächenfinish | Warmgewalzt, kaltgewalzt, geglüht, entrostet, poliert, bearbeitet |

| Maßtoleranz | ±0.1mm bis ±0.5mm (je nach Form und Größe) |

| Internationale Standards | ASTM B443, AMS 5599, UNS N06625, DIN 2.4856, EN 10216-5 |

| Wärmebehandlungszustand | Lösungsgeglüht, gealtert, spannungsarm |

| Prüfzertifikate | Mill Test Certificate (MTC), Material Test Certificate (3.1/3.2) |

Lassen Sie uns Erfolg für Ihr Projekt schaffen

Professionelles Team, Premium-Produkte, Vollständiger Service - Ihr Projekterfolg ist unsere Mission

Our Advantages in Processing GH3625

Fortgeschrittene Vakuum-Schmelztechnologie

MetalZenith setzt modernste Vakuum-Induktionsschmelzen (VIM) und Vakuum-Arc-Umschmelzen (VAR) ein, um eine überlegene chemische Homogenität zu erreichen und Einschlüsse zu beseitigen, was zu GH3625 mit außergewöhnlichen mechanischen Eigenschaften und verbesserter Ermüdungsbeständigkeit führt.

Umfassendes Qualitätskontrollsystem

Unser integriertes Qualitätsmanagementsystem bietet eine Echtzeit-Prozessüberwachung, fortschrittliche spektroskopische Analysen, mechanische Prüf laboratories und vollständige Rückverfolgbarkeit von Rohstoffen bis hin zu fertigen Produkten, um eine konsistente GH3625-Qualität zu gewährleisten, die die Branchenstandards übertrifft.

Benutzerdefinierte Verarbeitung & Globale Lieferung

MetalZenith bietet umfangreiche Anpassungsmöglichkeiten, einschließlich Präzisionsbearbeitung, Optimierung der Wärmebehandlung und spezialisierte Oberflächenbehandlungen. Unser globales Vertriebsnetz gewährleistet eine zuverlässige Versorgung mit GH3625 sowie technische Unterstützung und Ingenieurdienstleistungen weltweit.

IHR VERTRAUENwürdiger STAHL

HERSTELLUNGSPARTNER

Schnellanfrage

Branchen, die wir bedienen

Professionelle Stahl-Lösungen in wichtigen Branchen

Qualifikationen & Zertifizierungen