20 Jahre Erfahrung | 1000+ Markenpartner | Vollständige Anpassung

Wir haben 20 Jahre Branchenerfahrung, haben mit über 1.000 Marken zusammengearbeitet und unterstützen alle Anpassungsbedürfnisse.

Technical Specifications

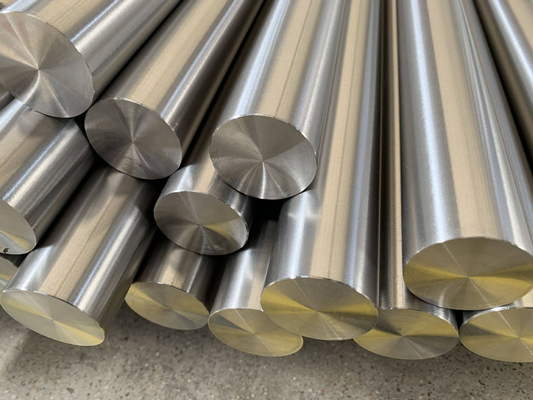

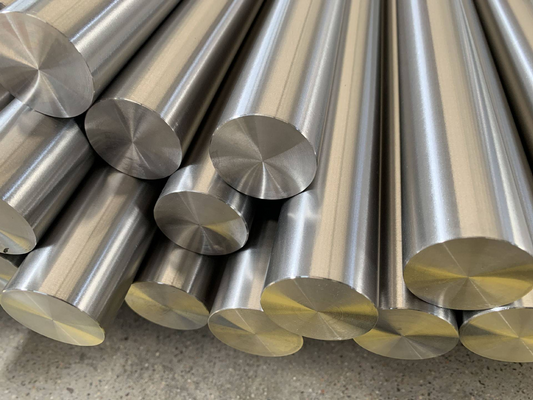

Product Overview

Metallurgische Eigenschaften

UNS N10276 weist eine kubisch flächenzentrierte (FCC) austenitische Struktur auf, die über einen breiten Temperaturbereich stabil bleibt. Die außergewöhnliche Korrosionsbeständigkeit der Legierung resultiert aus ihrem hohen Molybdän- und Chromgehalt, der in aggressiven Umgebungen einen schützenden passiven Film bildet. Der kontrollierte Schmelzprozess von MetalZenith gewährleistet eine gleichmäßige Verteilung der Legierungselemente, minimiert die Segregation und optimiert die Korrosionsleistung.

Wärmebehandlungsprozess

MetalZenith verwendet einen proprietären Lösungsglühen-Prozess bei 1120°C ± 15°C, gefolgt von einer schnellen Wasserabschreckung, um eine optimale Mikrostruktur zu erreichen. Diese Behandlung löst Karbide auf und gewährleistet eine einphasige austenitische Struktur, während die Korrosionsbeständigkeit maximiert wird. Die Nachglühbeizung entfernt die Wärmebehandlungs-Skalierung und Oberflächenkontamination und sorgt für eine überlegene Oberflächenqualität für kritische Anwendungen.

Exzellenz im Fertigungsprozess

Unser integrierter Fertigungsprozess beginnt mit der Vakuum-Induktionsschmelze (VIM) von hochwertigen Rohmaterialien, gefolgt von der Elektroschlacke-Umschmelzung (ESR) zur Verbesserung der Sauberkeit. Die Warmbearbeitungsprozesse nutzen kontrollierte Atmosphärenöfen und präzise Walz-/Schmiedeanlagen. Kaltbearbeitungsprozesse verwenden spezialisierte Werkzeuge, um die Maßgenauigkeit zu erhalten und gleichzeitig die Materialeigenschaften zu bewahren. Alle Vorgänge werden unter strengen Qualitätskontrollprotokollen mit Echtzeitüberwachung durchgeführt.

Qualitätsstandards & Prüfung

MetalZenith unterhält umfassende Qualitätssicherungsprogramme, die den Anforderungen von ISO 9001:2015, AS9100D und NADCAP entsprechen. Jede Charge unterliegt einer vollständigen chemischen Analyse mittels optischer Emissionsspektroskopie und Röntgenfluoreszenz. Die Überprüfung der mechanischen Eigenschaften umfasst Zugversuche, Härtemessungen und Schlagprüfungen gemäß ASTM-Standards. Spezialisierte Korrosionstests validieren die Leistung in spezifischen Umgebungen, während zerstörungsfreie Prüfungen die Materialintegrität entlang der Lieferkette sicherstellen.

🧪 Chemical Composition

| Element | Zusammensetzung (%) |

|---|---|

| Nickel (Ni) | Rest (min. 57.0) |

| Molybdän (Mo) | 15.0 - 17.0 |

| Chrom (Cr) | 14.5 - 16.5 |

| Eisen (Fe) | 4.0 - 7.0 |

| Wolfram (W) | 3.0 - 4.5 |

| Kobalt (Co) | ≤ 2.5 |

| Mangan (Mn) | ≤ 1.0 |

| Vanadium (V) | ≤ 0.35 |

| Silizium (Si) | ≤ 0.08 |

| Kohlenstoff (C) | ≤ 0.01 |

| Schwefel (S) | ≤ 0.03 |

| Phosphor (P) | ≤ 0.04 |

⚙️ Mechanical Properties

| Eigenschaft | Wert |

|---|---|

| Zugfestigkeit (Raumtemperatur) | ≥ 690 MPa (100 ksi) |

| Streckgrenze (0,2% Offset) | ≥ 283 MPa (41 ksi) |

| Dehnung in 50mm | ≥ 40% |

| Querschnittsreduktion | ≥ 65% |

| Härte (Rockwell B) | ≤ 100 HRB |

| Härte (Brinell) | ≤ 230 HB |

| Schlagenergie (Charpy V-Notch, Raumtemp) | ≥ 200 J (148 ft-lbs) |

| Ermüdungsfestigkeit (10&sup7; Zyklen) | 310 MPa (45 ksi) |

| Youngs Modul | 205 GPa (29.7 × 10&sup6; psi) |

| Schubmodul | 81 GPa (11.8 × 10&sup6; psi) |

| Poisson-Zahl | 0.31 |

🔬 Physical Properties

| Eigenschaft | Wert |

|---|---|

| Dichte | 8.89 g/cm³ (0.321 lb/in³) |

| Schmelzpunktbereich | 1370-1400°C (2500-2550°F) |

| Wärmeleitfähigkeit (100°C) | 10.1 W/m·K (70 BTU·in/hr·ft²·°F) |

| Wärmeleitfähigkeit (500°C) | 17.4 W/m·K (121 BTU·in/hr·ft²·°F) |

| Wärmeausdehnung (20-100°C) | 11.2×10-6/K (6.2×10-6/°F) |

| Wärmeausdehnung (20-500°C) | 12.4×10-6/K (6.9×10-6/°F) |

| Spezifische Wärme (20°C) | 427 J/kg·K (0.102 BTU/lb·°F) |

| Elektrische Widerstandsfähigkeit (20°C) | 1.29 µΩ·m (51 µΩ·in) |

| Magnetische Permeabilität | 1.002 (Im Wesentlichen nicht-magnetisch) |

| Curie-Temperatur | Nicht anwendbar |

📏 Product Specifications

| Spezifikation | Verfügbare Optionen |

|---|---|

| Produktformen | Rundstahl, Flachstahl, Platte, Blech, Streifen, Rohr, Rohrleitung, Draht, Schmiedebestände |

| Durchmesser Rundstahl | 6mm - 300mm (0.25" - 12") |

| Plattendicke | 3mm - 150mm (0.125" - 6") |

| Blechdicke | 0.5mm - 6mm (0.02" - 0.25") |

| Rohraußendurchmesser | 6mm - 200mm (0.25" - 8") |

| Einhaltung von Standards | ASTM B575, ASME SB-575, UNS N10276, DIN 2.4819, EN 10204-3.1 |

| Oberflächenfinish | Warmgewalzt, Kaltgewalzt, Geglüht, Beizt, Poliert (2B, BA, Spiegel) |

| Maßtoleranz | ASTM-Standard, Maßgeschneiderte Präzisionstoleranzen verfügbar |

| Längenoptionen | Standard: 3m, 6m, 12m | Maßgeschneiderte Längen bis zu 18m |

| Wärmebehandlungszustand | Lösungsgeglüht (1120°C), Schnelles Abschrecken, Maßgeschneiderte Wärmebehandlung |

| Prüfung & Zertifizierung | Werksprüfzertifikat, Drittanbieterinspektion, PMI, Mechanische Prüfung |

Lassen Sie uns Erfolg für Ihr Projekt schaffen

Professionelles Team, Premium-Produkte, Vollständiger Service - Ihr Projekterfolg ist unsere Mission

Our Advantages in Processing UNS N10276

Fortgeschrittene Vakuum-Schmelztechnologie

MetalZenith verwendet hochmoderne Vakuum-Induktionsschmelzverfahren (VIM) und Elektroschlacke-Umschmelzverfahren (ESR), um UNS N10276 mit außergewöhnlicher chemischer Homogenität und minimalem Einschlussgehalt herzustellen. Unsere kontrollierte Atmosphärenverarbeitung gewährleistet eine optimale metallurgische Struktur und konsistente mechanische Eigenschaften im gesamten Material.

Umfassende Qualitätskontrollsysteme

Unser integriertes Qualitätsmanagementsystem umfasst die Echtzeit-Chemieanalyse, fortschrittliche mechanische Prüfungen und spezielle Bewertungen der Korrosionsbeständigkeit. Die Laboreinrichtungen von MetalZenith verfügen über die neueste spektroskopische Ausrüstung und Korrosionsprüfkammern, um die Materialleistung gemäß den strengsten Branchenanforderungen zu überprüfen.

Benutzerdefinierte Verarbeitung & Globale Lieferkette

MetalZenith bietet umfangreiche Anpassungsmöglichkeiten, einschließlich Präzisionsbearbeitung, spezialisierter Wärmebehandlung und maßgeschneiderter Legierungsmodifikationen. Unser globales Vertriebsnetz gewährleistet eine zuverlässige Lieferung weltweit, während unser technisches Support-Team Ingenieure Unterstützung für anwendungsspezifische Anforderungen und die Optimierung der Materialauswahl bietet.

IHR VERTRAUENwürdiger STAHL

HERSTELLUNGSPARTNER

Schnellanfrage

Branchen, die wir bedienen

Professionelle Stahl-Lösungen in wichtigen Branchen

Qualifikationen & Zertifizierungen