20 лет опыта | 1000+ партнеров по брендам | Полная настройка

У нас 20 лет опыта в отрасли, мы сотрудничаем с более чем 1,000 брендами и поддерживаем любые потребности в настройке.

Technical Specifications

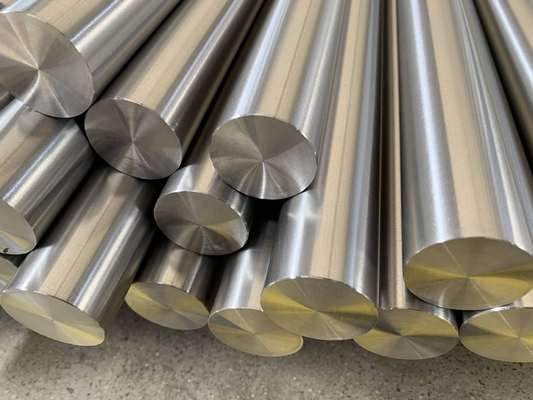

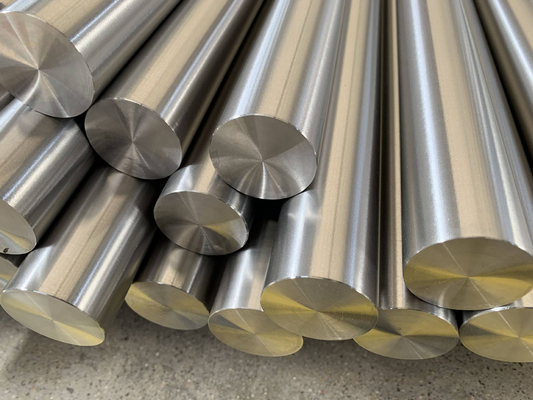

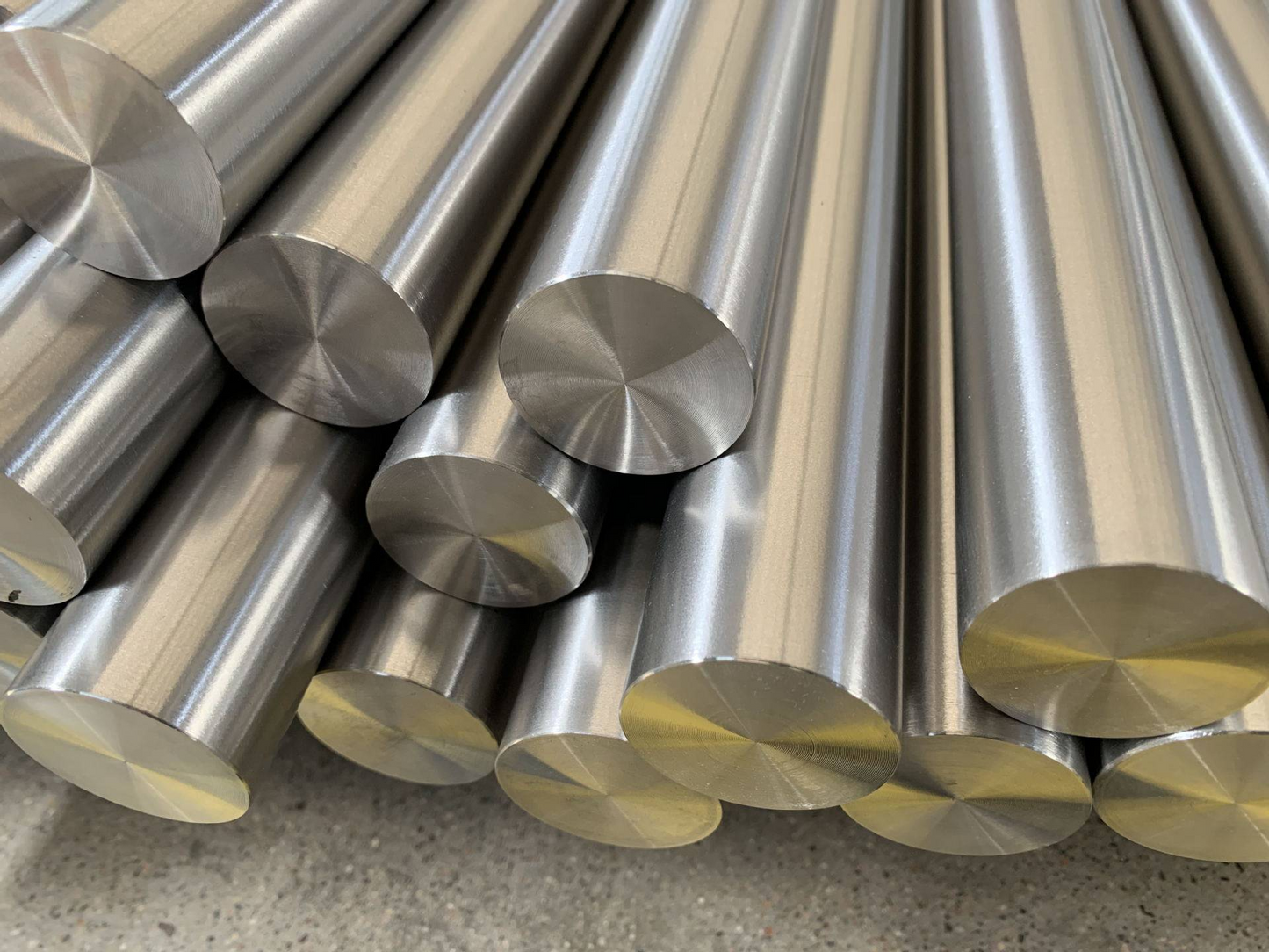

Product Overview

Металлургические характеристики

Морская сталь EH36 имеет мелкозернистую ферритно-перлитную микроструктуру, достигнутую благодаря контролируемой прокатке и нормализующей термообработке. Состав стали включает микроалюминиевые элементы, такие как ниобий, ванадий и титан, которые обеспечивают упрочнение зерна и осаждение. Это приводит к оптимальному сочетанию высокой прочности, отличной ударной вязкости и превосходной свариваемости, необходимых для морских конструкционных приложений.

Процесс термообработки

MetalZenith использует тщательно контролируемый процесс нормализации, при котором сталь EH36 нагревается до 900-950°C, удерживается при этой температуре для равномерного образования аустенита, а затем охлаждается на воздухе для достижения желаемой микроструктуры. Эта термообработка обеспечивает постоянные механические свойства по всей толщине материала и устраняет остаточные напряжения от горячей прокатки. Дополнительное отжиг для снятия напряжений при 580-650°C может быть применено для конкретных приложений, требующих размерной стабильности.

Совершенство производственного процесса

Наш интегрированный процесс производства стали начинается с плавки в электродуговой печи с использованием первоклассного лома и прямиком уменьшенного железа. Вторичная переработка через станции металлургии в ковшах обеспечивает точный контроль химического состава и модификацию включений. Сталь подвергается непрерывной литью, за которым следует термомеханическая контролируемая обработка (TMCP) с компьютерным управлением графиками прокатки для оптимизации структуры зерна и механических свойств. Современные ультразвуковые испытания и автоматизированные системы инспекции обеспечивают поставку бездефектного материала.

Стандарты качества и сертификация

Производство стали EH36 компанией MetalZenith соответствует самым высоким международным стандартам качества, включая ISO 9001:2015, ISO 14001:2015 и OHSAS 18001. Наша система управления качеством охватывает полную прослеживаемость материала, комплексные механические и химические испытания, неразрушающий контроль и проверку третьими сторонами крупными классификационными обществами. Каждая отгрузка включает сертифицированные заводские испытательные сертификаты с полными результатами испытаний и документацией о соответствии требованиям морской отрасли.

🧪 Chemical Composition

| Элемент | Состав (%) |

|---|---|

| Углерод (C) | ≤ 0.18 |

| Марганец (Mn) | 0.90 - 1.60 |

| Кремний (Si) | 0.10 - 0.50 |

| Фосфор (P) | ≤ 0.035 |

| Сера (S) | ≤ 0.035 |

| Алюминий (Al) | ≥ 0.015 |

| Ниобий (Nb) | 0.02 - 0.05 |

| Ванадий (V) | 0.05 - 0.10 |

| Титан (Ti) | 0.02 - 0.05 |

| Медь (Cu) | ≤ 0.35 |

| Хром (Cr) | ≤ 0.20 |

| Никель (Ni) | ≤ 0.40 |

| Молибден (Mo) | ≤ 0.08 |

⚙️ Mechanical Properties

| Свойство | Значение |

|---|---|

| Предел текучести (ReH) | ≥ 355 MPa |

| Предел прочности (Rm) | 490 - 630 MPa |

| Удлинение (A5) | ≥ 22% |

| Энергия удара (KV при 0°C) | ≥ 34 J |

| Энергия удара (KV при -20°C) | ≥ 24 J |

| Энергия удара (KV при -40°C) | ≥ 24 J |

| Твердость Бринелля (HB) | 150 - 220 |

| Модуль Юнга | 210 GPa |

| Коэффициент Пуассона | 0.30 |

| Предельная усталость (107 циклов) | 180 MPa |

| Критическая прочность (K1C) | 120 MPa·m1/2 |

🔬 Physical Properties

| Свойство | Значение |

|---|---|

| Плотность | 7.85 g/cm³ |

| Температура плавления | 1510°C |

| Теплопроводность (20°C) | 54 W/m·K |

| Коэффициент теплового расширения (20-100°C) | 12×10-6/K |

| Удельная теплоемкость | 500 J/kg·K |

| Электрическое сопротивление (20°C) | 0.16 µΩ·m |

| Магнитная проницаемость | Ферромагнитный |

| Температура Кюри | 770°C |

| Тепловая диффузия | 13.7 mm²/s |

| Эмиссия (окисленная поверхность) | 0.79 |

📏 Product Specifications

| Спецификация | Доступные варианты |

|---|---|

| Формы продукта | Пластины, Листы, Бруски, Секции, Кованые изделия |

| Толщина пластины | 6 - 150 мм |

| Толщина листа | 1.5 - 6 мм |

| Диапазон ширины | 1000 - 4000 мм |

| Диапазон длины | 2000 - 18000 мм |

| Стандарты | ABS, DNV-GL, LR, BV, CCS, NK, RINA |

| Обработка поверхности | Горячекатаный, Нормализованный, Пескоструйный |

| Состояние кромки | Мельничная кромка, Обрезанная кромка, Плазменная резка |

| Допуск по толщине | ± 0.3 мм (t ≤ 40мм), ± 0.05t (t > 40мм) |

| Допуск по ширине | ± 10 мм |

| Допуск по длине | ± 25 мм |

| Плоскостность | ≤ 5 мм/м |

Давайте создадим успех для вашего проекта

Профессиональная команда, премиум-продукты, полный сервис - успех вашего проекта является нашей миссией

Our Advantages in Processing EH36

Совершенная технология контролируемой прокатки

MetalZenith использует прецизионно контролируемые термомеханические прокатные процессы с мониторингом температуры в реальном времени и компьютерным управлением графиками деформации. Эта передовая технология обеспечивает оптимальное упрочнение зерна и однородные механические свойства по всему стали EH36, обеспечивая превосходные соотношения прочности к весу и повышенную прочность для морских приложений.

Комплексная морская сертификационная программа

Наш сталь EH36 проходит строгие испытательные протоколы, включая испытания на ударную вязкость по Шарпи при отрицательных температурах, ультразвуковую инспекцию и проверку третьими сторонами ведущими классификационными обществами. MetalZenith поддерживает сертификаты от ABS, DNV-GL, Lloyd's Register и других ведущих морских органов, обеспечивая полное соответствие международным стандартам судостроения.

Гибкая цепочка поставок и индивидуальная обработка

MetalZenith предлагает комплексные решения для управления цепочками поставок с стратегическим управлением запасами, доставкой точно в срок и индивидуальными услугами по обработке, включая резку, механическую обработку и термообработку. Наша глобальная сеть распределения и гибкое планирование производства обеспечивают надежные поставки стали EH36 в различных формах и спецификациях для удовлетворения конкретных требований проектов.

ВАШ НАДЕЖНЫЙ СТАЛЬ

ПАРТНЕР ПО ПРОИЗВОДСТВУ

Быстрый запрос

Отрасли, которые мы обслуживаем

Профессиональные стальные решения для основных отраслей

Квалификации и сертификаты