20 лет опыта | 1000+ партнеров по брендам | Полная настройка

У нас 20 лет опыта в отрасли, мы сотрудничаем с более чем 1,000 брендами и поддерживаем любые потребности в настройке.

Technical Specifications

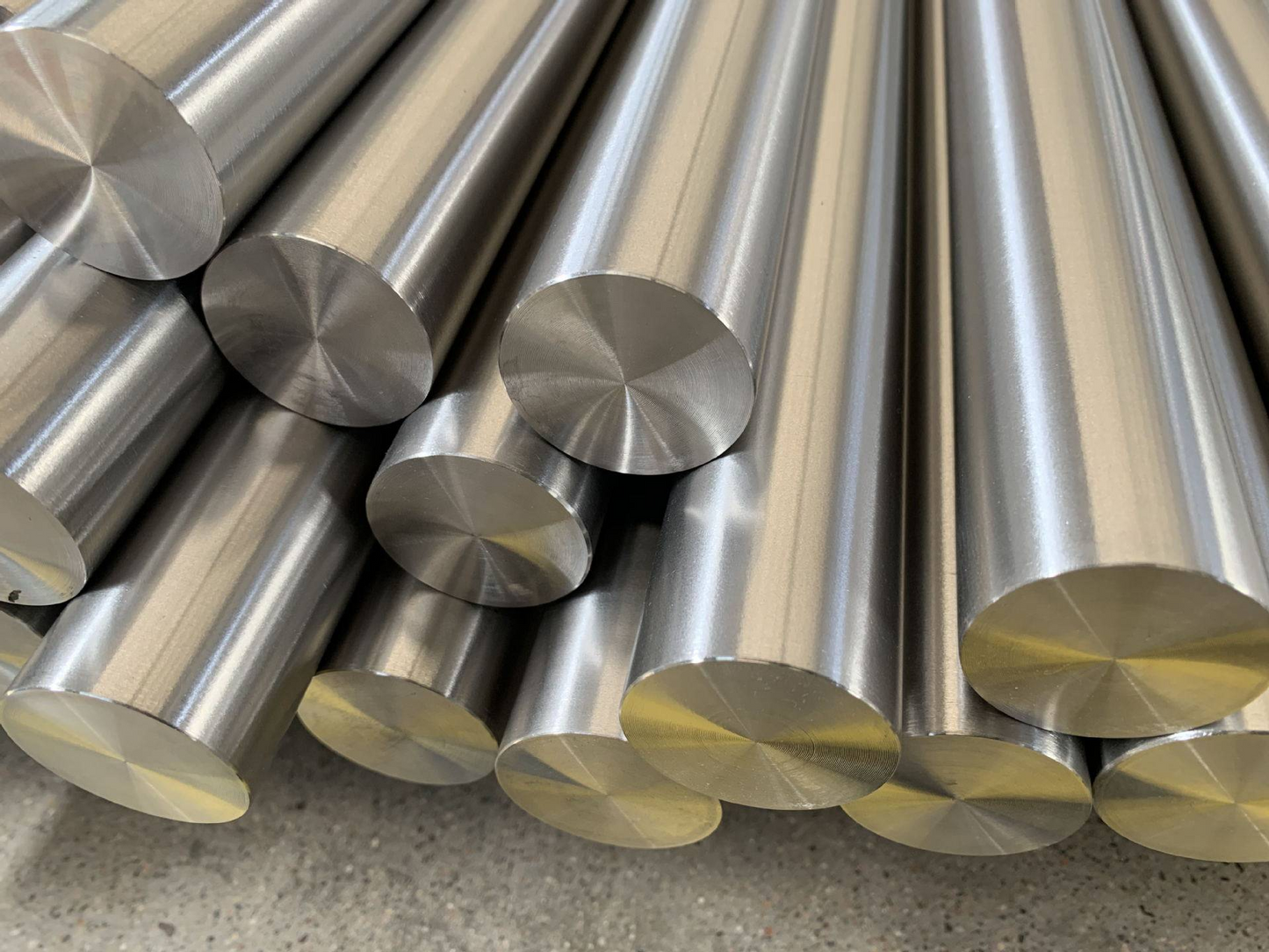

Product Overview

Металлургические характеристики

DP780 имеет сложную двуфазную микроструктуру, состоящую из мягкой матрицы феррита (60-80%), усиленной твердыми островками мартенсита (20-40%). Эта уникальная микроструктурная организация обеспечивает исключительное поведение упрочнения при деформации и характеристики непрерывной текучести, что делает ее идеальной для сложных операций формовки в структурных приложениях. Мелкозернистая матрица феррита обеспечивает отличную пластичность, в то время как дисперсная фаза мартенсита способствует высокой прочности и улучшенным способностям к поглощению энергии.

Процесс термообработки

MetalZenith использует передовую технологию непрерывного отжига с точным контролем интеркритической температуры при 750-820°C, за которой следует контролируемое охлаждение для достижения оптимальной двуфазной микроструктуры. Наш запатентованный термический цикл включает быстрое охлаждение через критический температурный диапазон для формирования желаемой доли мартенсита, обеспечивая постоянные механические свойства и превосходные характеристики формуемости, необходимые для структурных приложений.

Совершенство производственного процесса

Наш современный производственный объект использует технологию контролируемой прокатки в сочетании с прецизионным отжигом для достижения равномерного распределения микроструктуры. Современные системы контроля процессов отслеживают химический состав, температурные профили и скорости охлаждения в реальном времени, обеспечивая постоянное качество и механические свойства на протяжении каждой катушки и партии для надежной структурной производительности.

Специализированное качество тестирования

MetalZenith проводит комплексные протоколы тестирования, специально разработанные для структурных приложений: оценка производительности точечной сварки по стандартам автомобильной промышленности, анализ пределов сложной формовки с помощью тестирования Накаджима, испытания на усталость при высоком цикле под переменной амплитудой нагрузки и испытания на коррозию в солевом распылении в соответствии с ASTM B117 для проверки атмосферной коррозионной стойкости для наружных структурных приложений.

Инженерия структурных приложений

Для строительных конструкций и мостового проектирования DP780 с высоким соотношением прочности к весу позволяет создавать более легкие структурные конструкции, сохраняя при этом коэффициенты безопасности. В производстве автомобильных шасси и машин отличная формуемость позволяет создавать сложные геометрии без ущерба для структурной целостности. Превосходные характеристики поглощения энергии делают его особенно подходящим для критически важных структурных компонентов в производстве автомобилей и общих инженерных приложениях, где сопротивление ударам имеет первостепенное значение.

🧪 Chemical Composition

| Элемент | Состав (%) |

|---|---|

| Углерод (C) | 0.05 - 0.10 |

| Марганец (Mn) | 1.50 - 2.50 |

| Кремний (Si) | 0.20 - 0.70 |

| Фосфор (P) | ≤ 0.030 |

| Сера (S) | ≤ 0.015 |

| Алюминий (Al) | 0.020 - 0.070 |

| Хром (Cr) | 0.10 - 0.50 |

| Молибден (Mo) | 0.05 - 0.25 |

⚙️ Mechanical Properties

| Свойство | Значение |

|---|---|

| Предел текучести (МПа) | 480 - 600 |

| Предел прочности на растяжение (МПа) | 780 - 950 |

| Удлинение (%) | ≥ 14 |

| Энергия удара при 20°C (Дж) | ≥ 40 |

| Твердость (HV) | 240 - 300 |

| Выносливость (МПа) | ≥ 350 |

🔬 Physical Properties

| Свойство | Значение |

|---|---|

| Плотность (г/см3) | 7.85 |

| Температура плавления (°C) | 1510 - 1540 |

| Теплопроводность (Вт/м·К) | 48.5 |

| Тепловое расширение (×10??/K) | 11.8 |

| Модуль упругости (ГПа) | 210 |

| Коэффициент Пуассона | 0.30 |

📏 Product Specifications

| Спецификация | Детали |

|---|---|

| Доступные формы | Листы, Катушки, Пластины, Полосы, Индивидуальные заготовки |

| Диапазон толщины | 0.5 - 8.0мм |

| Диапазон ширины | 600 - 2100мм |

| Диапазон длины | 1000 - 6000мм |

| Соответствие стандартам | ASTM A1011, SAE J2340, EN 10338 |

| Состояние поверхности | Горячекатаный, Холоднокатаный, Оцинкованный |

| Термическая обработка | Непрерывно отожженный, Двойная фаза |

Давайте создадим успех для вашего проекта

Профессиональная команда, премиум-продукты, полный сервис - успех вашего проекта является нашей миссией

Our Advantages in Processing Сталь DP780

Управление микроструктурой с двумя фазами на продвинутом уровне

MetalZenith использует прецизионное интеркритическое отжиг с контролируемыми скоростями охлаждения для достижения оптимального баланса микроструктуры феррит-мартенсит. Наши передовые термические процессы обеспечивают стабильные механические свойства и превосходную формуемость, сохраняя при этом высокие характеристики прочности на протяжении всего материала.

Комплексное испытание структурной производительности

Наша программа обеспечения качества включает специализированное тестирование для структурных приложений: оценка производительности сварки, тестирование сложного моделирования формования, оценка прочности на усталость при высоких циклах и тестирование ускоренной коррозионной стойкости в атмосфере для обеспечения оптимальной производительности в сложных структурных условиях.

Пользовательская обработка и инженерная поддержка

MetalZenith предоставляет индивидуальные решения по обработке, включая специальные циклы термообработки, услуги по точному формованию и всестороннюю техническую поддержку. Наша инженерная команда предлагает рекомендации, специфичные для применения, для оптимизации структурного дизайна и разработки производственных процессов.

ВАШ НАДЕЖНЫЙ СТАЛЬ

ПАРТНЕР ПО ПРОИЗВОДСТВУ

Быстрый запрос

Отрасли, которые мы обслуживаем

Профессиональные стальные решения для основных отраслей

Квалификации и сертификаты