20 лет опыта | 1000+ партнеров по брендам | Полная настройка

У нас 20 лет опыта в отрасли, мы сотрудничаем с более чем 1,000 брендами и поддерживаем любые потребности в настройке.

Technical Specifications

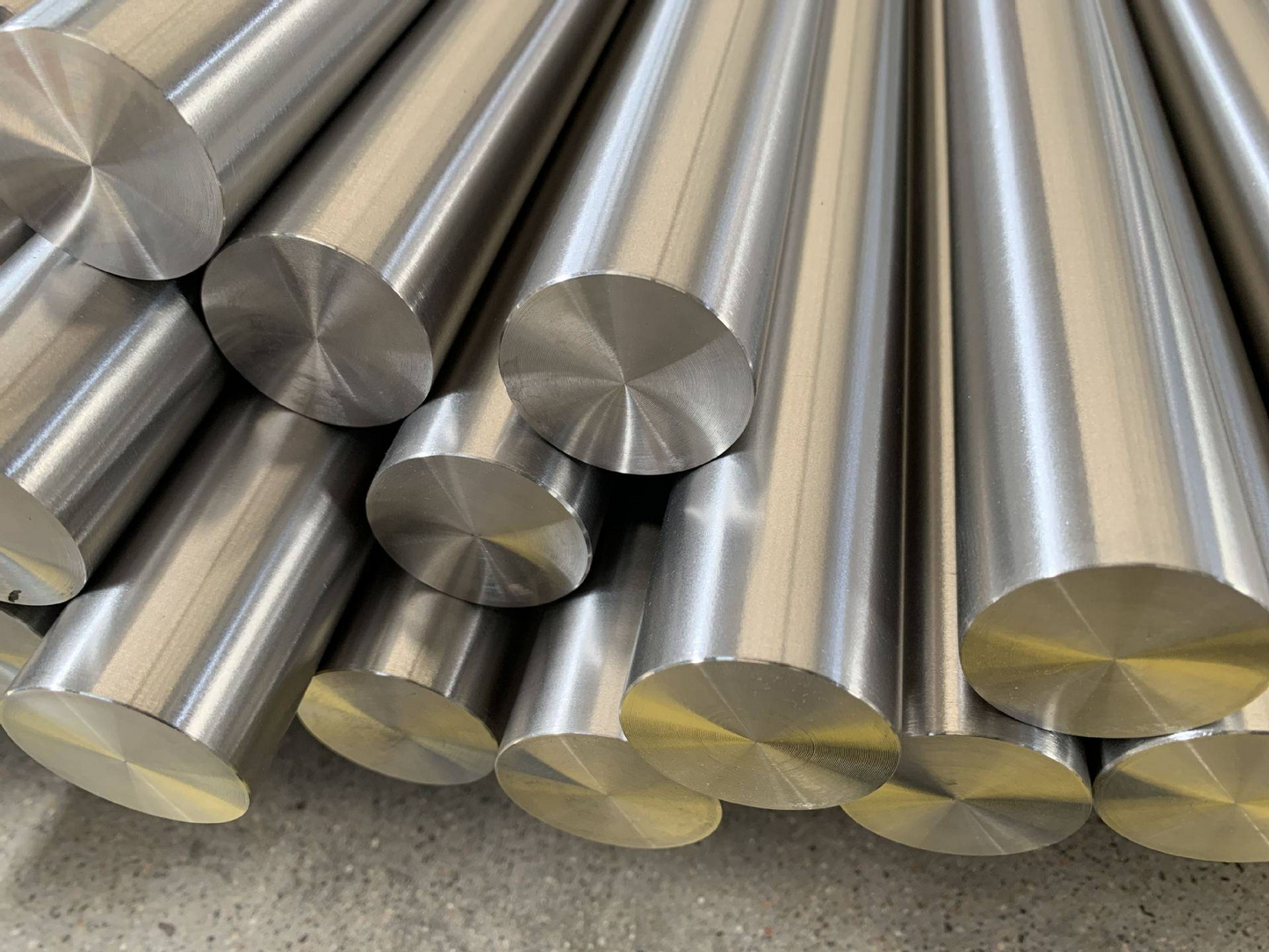

Product Overview

Металлургические характеристики

Сталь M2 для инструментов обладает сложной микроструктурой, состоящей из закаленной мартенситной матрицы с равномерно распределенными первичными и вторичными карбидами. Высокое содержание вольфрама и молибдена обеспечивает исключительную красную твердость и износостойкость, в то время как карбиды ванадия способствуют превосходному удержанию режущей кромки. Тонкое распределение карбидов, достигнутое благодаря контролируемому процессу затвердевания MetalZenith, обеспечивает оптимальную производительность инструмента.

Процесс термообработки

MetalZenith использует вакуумное закаливание при 1210-1230°C, за которым следует контролируемое охлаждение и несколько циклов отпускания при 540-580°C. Наши точные протоколы термообработки обеспечивают оптимальное распределение твердости, минимизируя содержание остаточного аустенита ниже 8%. Криогенная обработка при -80°C доступна для повышения размерной стабильности и износостойкости.

Процесс производства

MetalZenith использует вакуумное индукционное плавление, за которым следует электрошлаковая переплавка для достижения превосходной чистоты и распределения карбидов. Наши контролируемые процессы ковки и прокатки обеспечивают оптимальное течение зерна и механические свойства. Доступны современные маршруты порошковой металлургии для приложений, требующих ультратонкого распределения карбидов и изотропных свойств.

Специализированное качество тестирования

Наш комплексный протокол тестирования включает картирование твердости по Роквеллу по сечению, рентгеновский дифракционный анализ для количественной оценки остаточного аустенита, металлографическую оценку размера и распределения карбидов, а также испытания на усталость с вращающейся балкой при различных уровнях напряжения. Ультразвуковая инспекция обеспечивает внутреннюю целостность, критически важную для высокопроизводительных инструментальных приложений.

Инженерия применения

Для приложений с режущими инструментами M2 обеспечивает отличный баланс твердости и прочности с превосходным удержанием кромки. В холодных формовочных матрицах высокая прочность на сжатие и износостойкость обеспечивают длительный срок службы инструмента. Для производства подшипников тонкая структура карбидов и высокая твердость обеспечивают исключительное сопротивление усталости при качении. Компоненты прецизионной механики выигрывают от размерной стабильности и постоянных механических свойств, в то время как автомобильные приложения используют надежность материала при циклических нагрузках.

🧪 Chemical Composition

| Элемент | Состав (%) |

|---|---|

| Углерод (C) | 0.78 - 0.88 |

| Хром (Cr) | 3.75 - 4.50 |

| Молибден (Mo) | 4.50 - 5.50 |

| Вольфрам (W) | 5.50 - 6.75 |

| Ванадий (V) | 1.75 - 2.20 |

| Кремний (Si) | 0.20 - 0.45 |

| Марганец (Mn) | 0.15 - 0.40 |

| Фосфор (P) | ≤ 0.030 |

| Сера (S) | ≤ 0.030 |

⚙️ Mechanical Properties

| Свойство | Значение |

|---|---|

| Твердость (HRC) | 63 - 65 |

| Прочность на сжатие (MPa) | ≥ 4000 |

| Ударная вязкость (J) | 15 - 25 |

| Индекс износостойкости | 8.5 - 9.2 |

| Закаляемость (мм) | ≥ 75 |

| Красная твердость при 600°C (HRC) | ≥ 58 |

🔬 Physical Properties

| Свойство | Значение |

|---|---|

| Плотность (г/см3) | 8.16 |

| Температура плавления (°C) | 1480 - 1520 |

| Теплопроводность (Вт/м·К) | 24.3 |

| Тепловое расширение (×10??/К) | 10.8 |

| Модуль упругости (ГПа) | 230 |

| Коэффициент Пуассона | 0.27 |

📏 Product Specifications

| Спецификация | Детали |

|---|---|

| Доступные формы | Бруски, прутки, пластины, кованые изделия, порошок |

| Диапазон диаметра | 6 - 500мм |

| Диапазон толщины | 3 - 200мм |

| Диапазон длины | 100 - 6000мм |

| Соответствие стандартам | ASTM A600, AISI M2, DIN 1.3343 |

| Условие термообработки | Отожженное, закаленное и отпускное |

| Обработка поверхности | Шлифованное, токарное, бесцентровое шлифование |

Давайте создадим успех для вашего проекта

Профессиональная команда, премиум-продукты, полный сервис - успех вашего проекта является нашей миссией

Our Advantages in Processing Сталь инструментальная M2

Совершенная вакуумная плавильная технология

MetalZenith использует процессы вакуумного индукционного плавления и электрошлакового переплавления с точным контролем температуры для достижения оптимального распределения карбидов и устранения включений. Наша передовая технология плавления обеспечивает постоянный химический состав и превосходную металлургическую чистоту по всему материалу.

Комплексное тестирование инструментальной стали

MetalZenith проводит специализированные испытания, включая картирование твердости по Роквеллу по сечению, анализ содержания остаточного аустенита с помощью рентгеновской дифракции, оценку распределения карбидов с помощью металлографического анализа и испытания на усталость с вращающейся балкой для обеспечения оптимальной производительности и долговечности инструмента.

Услуги по индивидуальной термической обработке

MetalZenith предлагает специализированные услуги термообработки, включая вакуумную закалку, точные циклы отпускания и криогенную обработку. Наши металлургические инженеры предоставляют техническую поддержку для оптимальных профилей твердости и размерной стабильности, адаптированных к конкретным инструментальным приложениям.

ВАШ НАДЕЖНЫЙ СТАЛЬ

ПАРТНЕР ПО ПРОИЗВОДСТВУ

Быстрый запрос

Отрасли, которые мы обслуживаем

Профессиональные стальные решения для основных отраслей

Квалификации и сертификаты