20 лет опыта | 1000+ партнеров по брендам | Полная настройка

У нас 20 лет опыта в отрасли, мы сотрудничаем с более чем 1,000 брендами и поддерживаем любые потребности в настройке.

Technical Specifications

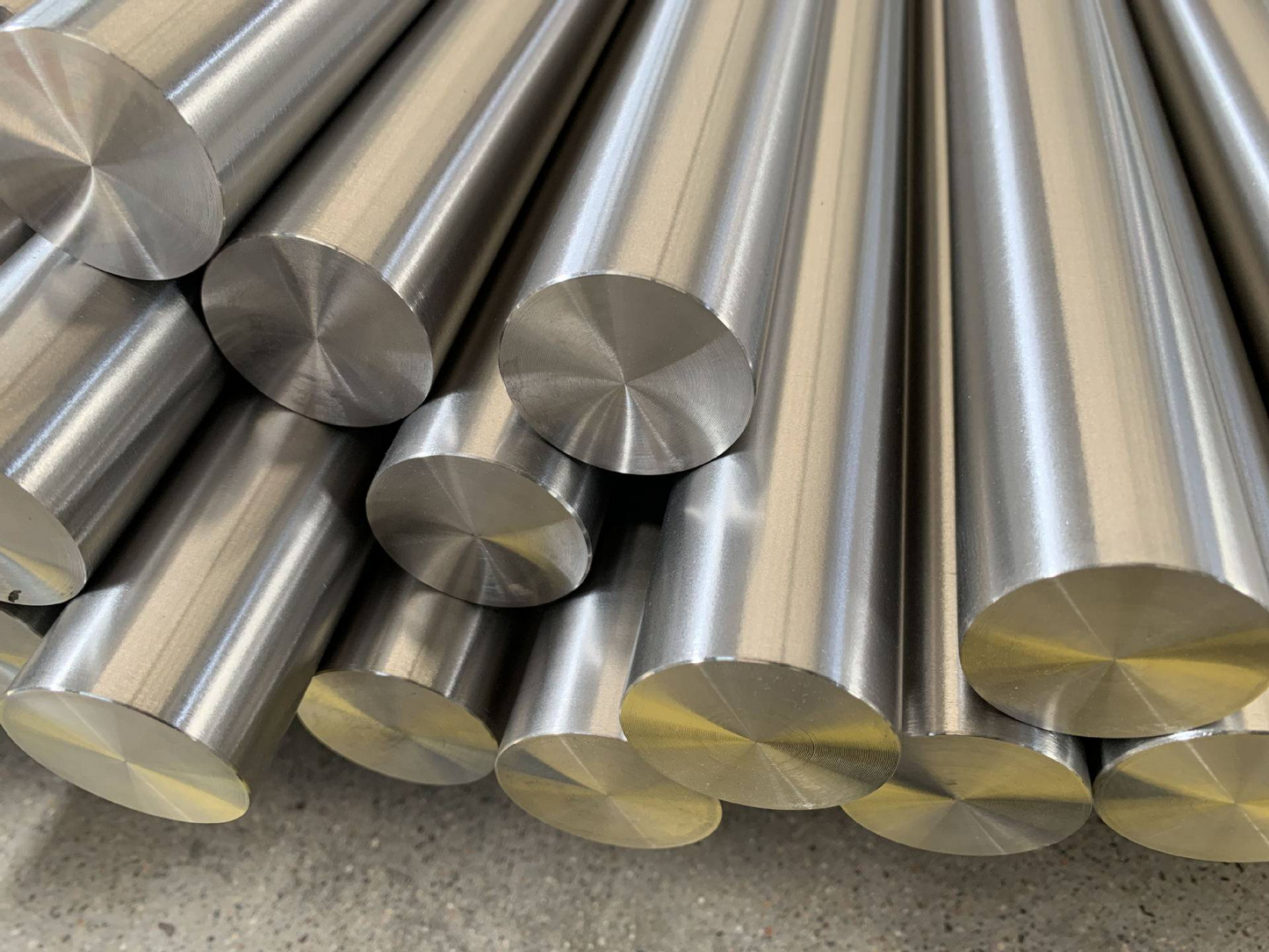

Product Overview

Металлургические характеристики

AISI H21 - это сталь для горячей обработки типа вольфрам, характеризующаяся высоким содержанием вольфрама (8.5-10.0%), что обеспечивает исключительную прочность при высоких температурах и стойкость к термическому шоку. Микроструктура стали состоит из закаленной мартенситной матрицы с равномерно распределенными карбидами вольфрама и ванадия. Эти карбиды сохраняют свою твердость и износостойкость при повышенных температурах, что делает H21 идеальным для горячих процессов обработки. Содержание хрома (3.0-3.75%) улучшает закаливаемость и обеспечивает умеренную коррозионную стойкость.

Процесс термообработки

MetalZenith использует прецизионно контролируемые циклы термообработки, оптимизированные для AISI H21. Отжиг проводится при 870-900°C с последующим медленным охлаждением для достижения максимальной обрабатываемости. Закалка включает предварительный нагрев до 650-700°C, затем нагрев до 1000-1030°C в защитной атмосфере, после чего следует воздушное охлаждение или закалка в масле в зависимости от размера секции. Темперирование проводится при 540-650°C для достижения желаемой рабочей твердости 42-48 HRC. Рекомендуется двойное темперирование для обеспечения размерной стабильности и снятия напряжений.

Совершенство производственного процесса

Наш производственный процесс начинается с вакуумного индукционного плавления (VIM) с использованием высокочистых сырьевых материалов, за которым следует электрошлаковая переплавка (ESR) для устранения включений и достижения исключительной чистоты. Бруски подвергаются контролируемой ковке и прокатке для уточнения зернистой структуры и обеспечения равномерного распределения карбидов. Горячая обработка выполняется в диапазоне температур 1150-850°C с тщательным контролем скорости деформации, чтобы предотвратить трещины. Все продукты проходят комплексное ультразвуковое тестирование, химический анализ и проверку механических свойств.

Стандарты качества и сертификаты

MetalZenith поддерживает сертификат ISO 9001:2015 и соответствует международным стандартам, включая ASTM A681, EN ISO 4957 и JIS SKD61. Наша лаборатория контроля качества оснащена современным испытательным оборудованием, включая спектрометры оптического эмиссионного анализа, универсальные испытательные машины, приборы для измерения твердости и системы металлографического анализа. Каждая партия проходит строгие испытания, включая проверку химического состава, испытания механических свойств, исследование микроструктуры и измерение размеров. Полная прослеживаемость материалов и документация о сертификатах предоставляются с каждой отправкой.

🧪 Chemical Composition

| Элемент | Состав (%) |

|---|---|

| Углерод (C) | 0.28 - 0.35 |

| Марганец (Mn) | 0.15 - 0.40 |

| Кремний (Si) | 0.15 - 0.40 |

| Фосфор (P) | ≤ 0.030 |

| Сера (S) | ≤ 0.030 |

| Хром (Cr) | 3.00 - 3.75 |

| Вольфрам (W) | 8.50 - 10.00 |

| Ванадий (V) | 0.30 - 0.60 |

| Никель (Ni) | ≤ 0.30 |

| Молибден (Mo) | ≤ 0.30 |

| Медь (Cu) | ≤ 0.25 |

⚙️ Mechanical Properties

| Свойство | Значение | Состояние |

|---|---|---|

| Устойчивость к растяжению | 1380 - 1520 МПа | Закаленный и отпускной |

| Предельная прочность (0.2% смещение) | 1240 - 1380 МПа | Закаленный и отпускной |

| Удлинение | 8 - 12% | Закаленный и отпускной |

| Снижение площади | 25 - 35% | Закаленный и отпускной |

| Твердость (HRC) | 42 - 48 | Рабочая твердость |

| Твердость (HRC) | 52 - 58 | Максимальная твердость |

| Энергия удара (Charpy V-notch) | 15 - 25 Дж | Комнатная температура |

| Предельная усталость | 620 - 690 МПа | 10&sup7; циклов |

| Модуль упругости | 210 - 220 ГПа | Комнатная температура |

| Коэффициент Пуассона | 0.27 - 0.30 | Комнатная температура |

🔬 Physical Properties

| Свойство | Значение | Температура |

|---|---|---|

| Плотность | 8.15 g/cm³ | 20°C |

| Температура плавления | 1480 - 1520°C | - |

| Теплопроводность | 24.5 W/m·K | 20°C |

| Теплопроводность | 28.8 W/m·K | 400°C |

| Коэффициент теплового расширения | 11.2×10-6/K | 20-100°C |

| Коэффициент теплового расширения | 12.8×10-6/K | 20-400°C |

| Удельная теплоемкость | 460 J/kg·K | 20°C |

| Электрическое сопротивление | 0.65 µΩ·m | 20°C |

| Магнитная проницаемость | Ферромагнитный | Комнатная температура |

| Тепловая диффузия | 6.5×10-6 m²/s | 20°C |

📏 Product Specifications

| Спецификация | Доступные варианты | Стандарты |

|---|---|---|

| Формы продукта | Круглые прутки, плоские прутки, пластины, блоки, кованые изделия | ASTM A681 |

| Диаметр круглого прутка | 10 - 500 мм | ASTM A681 |

| Толщина плоского прутка | 8 - 150 мм | ASTM A681 |

| Толщина пластины | 20 - 300 мм | ASTM A681 |

| Размеры блока | До 1000×500×300 мм | Индивидуально |

| Обработка поверхности | Горячая прокатка, отжиг, токарная обработка, шлифовка | ASTM A681 |

| Допуск по размерам | ±0.5 мм (стандартный), ±0.1 мм (точный) | ISO 2768 |

| Длина | До 6000 мм (стандартный), доступна большая длина | Индивидуально |

| Условия термической обработки | Отожженное, нормализованное, закаленное и отпускное | ASTM A681 |

| Стандарты качества | ISO 9001:2015, ASTM A681, EN ISO 4957 | Международный |

Давайте создадим успех для вашего проекта

Профессиональная команда, премиум-продукты, полный сервис - успех вашего проекта является нашей миссией

Our Advantages in Processing AISI H21

Совершенная вакуумная плавильная технология

MetalZenith использует процессы вакуумного индукционного плавления (VIM) и электрошлакового переплавления (ESR) для производства AISI H21 с исключительной чистотой и однородностью. Наше плавление в контролируемой атмосфере устраняет включения и обеспечивает оптимальное распределение карбидов, что приводит к превосходным механическим свойствам и увеличенному сроку службы инструмента.

Точное управление термической обработкой

Наши современные установки для термической обработки оснащены компьютерами, контролирующими печи с точным поддержанием температуры и контролем атмосферы. Мы применяем запатентованные циклы термической обработки, оптимизированные для AISI H21, обеспечивая постоянные профили твердости, размерную стабильность и максимальную стойкость к термическому шоку для всех форм продукции.

Полная настройка и техническая поддержка

MetalZenith предлагает комплексные услуги по настройке, включая точную механическую обработку, обработку поверхностей и термическую обработку, специфичную для применения. Наша команда металлургических инженеров предоставляет технические консультации, анализ отказов и услуги по оптимизации инструментов, поддерживаемые нашей глобальной цепочкой поставок и возможностями быстрой доставки.

ВАШ НАДЕЖНЫЙ СТАЛЬ

ПАРТНЕР ПО ПРОИЗВОДСТВУ

Быстрый запрос

Отрасли, которые мы обслуживаем

Профессиональные стальные решения для основных отраслей

Квалификации и сертификаты