20年の経験 | 1000以上のブランドパートナー | 完全なカスタマイズ

私たちは20年の業界経験があり、1,000以上のブランドと提携し、あらゆるカスタマイズニーズをサポートしています。

Technical Specifications

Product Overview

冶金特性

S50Cは、適切に熱処理された場合、主にパーライト微細構造と細かい炭化物分布を示します。中炭素含有量は、強度と延性の最適なバランスを提供し、制御されたマンガン含有量は、硬化性と構造の均一性を向上させます。MetalZenithの制御冷却プロセスは、優れた構造性能のために一貫した粒子サイズと炭化物形態を確保します。

熱処理プロセス

MetalZenithは、850-900°Cでの正規化を含む精密熱処理サイクルを採用し、その後制御冷却、または820-860°Cからの急冷と550-650°Cでの焼戻しを行います。私たちのコンピュータ制御炉は、温度の均一性を±5°Cで維持し、材料の断面全体で一貫した機械的特性と最適な微細構造の発展を保証します。

製造プロセスの卓越性

私たちのS50C生産は、電気アーク炉溶解、二次精製、連続鋳造、制御された圧延プロセスを利用しています。高度な inclusion control と脱ガス技術は、優れた清浄度と構造的完全性を確保します。生産全体にわたるリアルタイムの品質監視は、一貫した化学組成と機械的特性を保証します。

専門的な品質テスト

MetalZenithは、構造用途に特化した包括的なテストを実施します:溶接性能評価(HAZ靭性テストを含む)、曲げ試験による成形能力評価、サイクリック荷重条件下での疲労強度の決定、ASTM基準に従った大気腐食抵抗テスト。これらの専門的なテストは、S50C鋼が厳しい構造工学の要件を満たすことを保証します。

構造用途工学

建設用に、S50Cは予測可能な応力-ひずみ挙動を持つ優れた耐荷重能力を提供します。橋梁工学においては、材料の疲労抵抗と溶接性が長期的な構造的完全性を確保します。機械製造においては、強度と加工性の組み合わせが複雑な部品の製造を可能にします。車両製造において、S50Cはシャーシやフレーム用途に最適な強度対重量比を提供し、一般的な工学はその多様な加工能力と信頼性のある機械的特性から恩恵を受けます。

🧪 Chemical Composition

| 元素 | 組成 (%) |

|---|---|

| 炭素 (C) | 0.47 - 0.53 |

| マンガン (Mn) | 0.60 - 0.90 |

| シリコン (Si) | 0.15 - 0.35 |

| リン (P) | ≤ 0.030 |

| 硫黄 (S) | ≤ 0.035 |

| クロム (Cr) | ≤ 0.20 |

| ニッケル (Ni) | ≤ 0.20 |

| 銅 (Cu) | ≤ 0.30 |

⚙️ Mechanical Properties

| 特性 | 値 |

|---|---|

| 降伏強度 (MPa) | ≥ 355 |

| 引張強度 (MPa) | 610 - 760 |

| 伸び (%) | ≥ 17 |

| 20°Cでの衝撃エネルギー (J) | ≥ 39 |

| 硬度 (HB) | 179 - 229 |

| 疲労強度 (MPa) | 290 - 320 |

🔬 Physical Properties

| 特性 | 値 |

|---|---|

| 密度 (g/cm3) | 7.85 |

| 融点 (°C) | 1460 - 1520 |

| 熱伝導率 (W/m·K) | 51.9 |

| 熱膨張 (×10??/K) | 11.5 |

| 弾性係数 (GPa) | 210 |

| ポアソン比 | 0.27 - 0.30 |

📏 Product Specifications

| 仕様 | 詳細 |

|---|---|

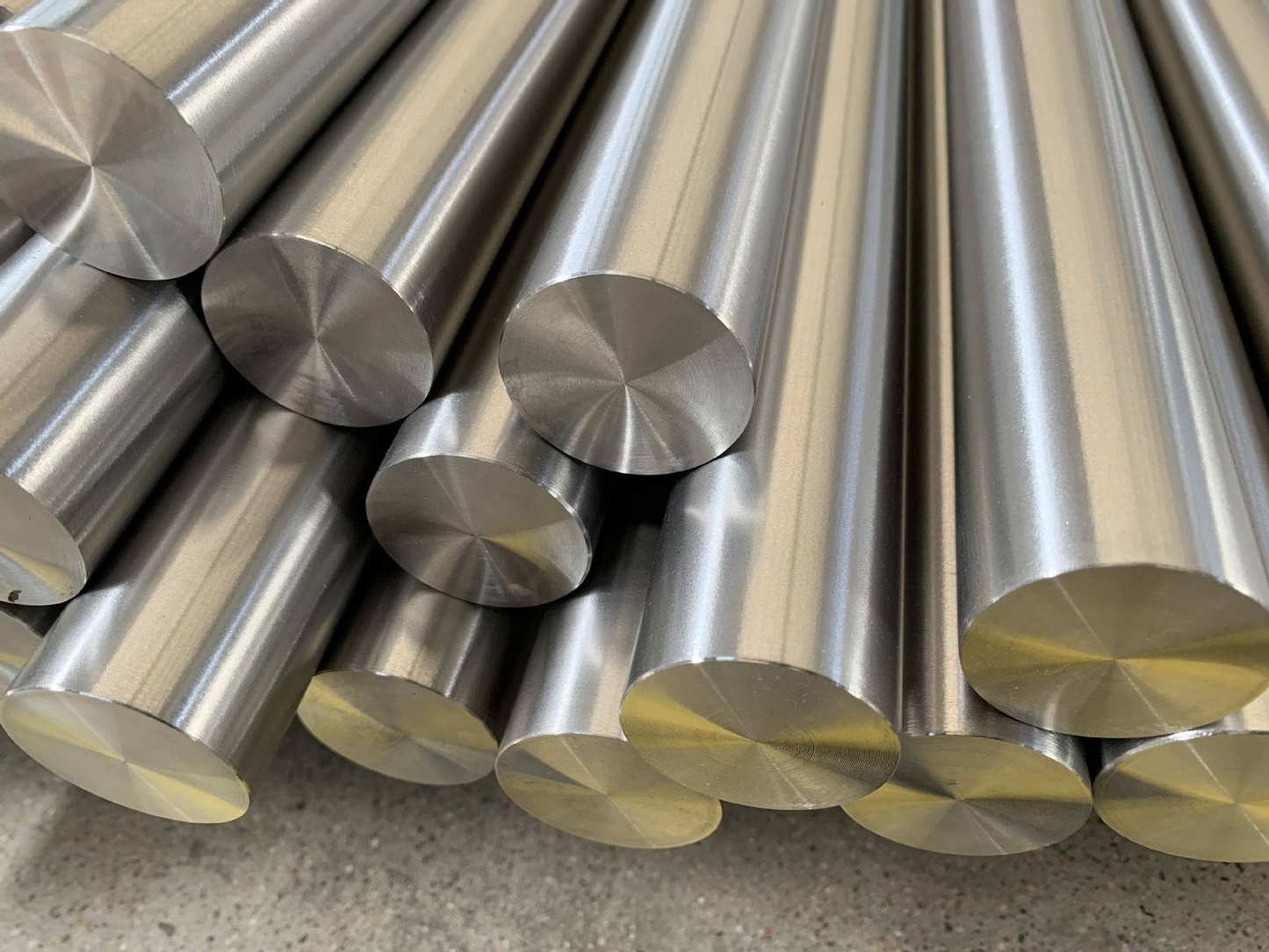

| 利用可能な形状 | プレート、バー、ロッド、構造セクション、鍛造品 |

| 厚さ範囲 | 5 - 200mm |

| 幅範囲 | 100 - 3000mm |

| 長さ範囲 | 1000 - 12000mm |

| 規格適合 | JIS G4051、ASTM A29、DIN C50、GB 45# |

| 熱処理条件 | 正規化、焼入れ&焼戻し、アニーリング |

| 表面仕上げ | 熱間圧延、冷間引抜き、機械加工、研磨 |

あなたのプロジェクトの成功を共に創りましょう

プロフェッショナルチーム、プレミアム製品、完全なサービス - あなたのプロジェクトの成功は私たちの使命です

Our Advantages in Processing S50C鋼

高度な熱処理技術

MetalZenithは、S50C鋼の最適な微細構造の精製を達成するために、コンピュータ制御の温度監視を伴う精密制御された焼入れおよび焼戻しプロセスを利用しています。当社の高度な熱処理設備は、材料の断面全体にわたって一貫した硬度分布と強化された機械的特性を保証します。

包括的な構造テスト

私たちの品質保証プログラムには、構造用途に特化したテストが含まれています:溶接性能評価、成形能力評価、サイクリック荷重下での疲労強度テスト、および大気腐食抵抗分析。これらのテストは、S50C鋼が厳しい構造工学の要件を満たしていることを保証します。

カスタム処理およびエンジニアリングサポート

MetalZenithは、S50C鋼部品のためのカスタマイズされた熱処理スケジュール、精密加工、およびカスタム成形サービスを提供しています。私たちの技術チームは、構造プロジェクトのための応力分析、接合設計の相談、および用途特有の材料最適化を含む包括的なエンジニアリングサポートを提供します。

あなたの信頼できる 鋼

製造パートナー

クイックお問い合わせ

私たちが提供する業界

主要産業向けのプロフェッショナルな鋼ソリューション

資格と認証