20年の経験 | 1000以上のブランドパートナー | 完全なカスタマイズ

私たちは20年の業界経験があり、1,000以上のブランドと提携し、あらゆるカスタマイズニーズをサポートしています。

Technical Specifications

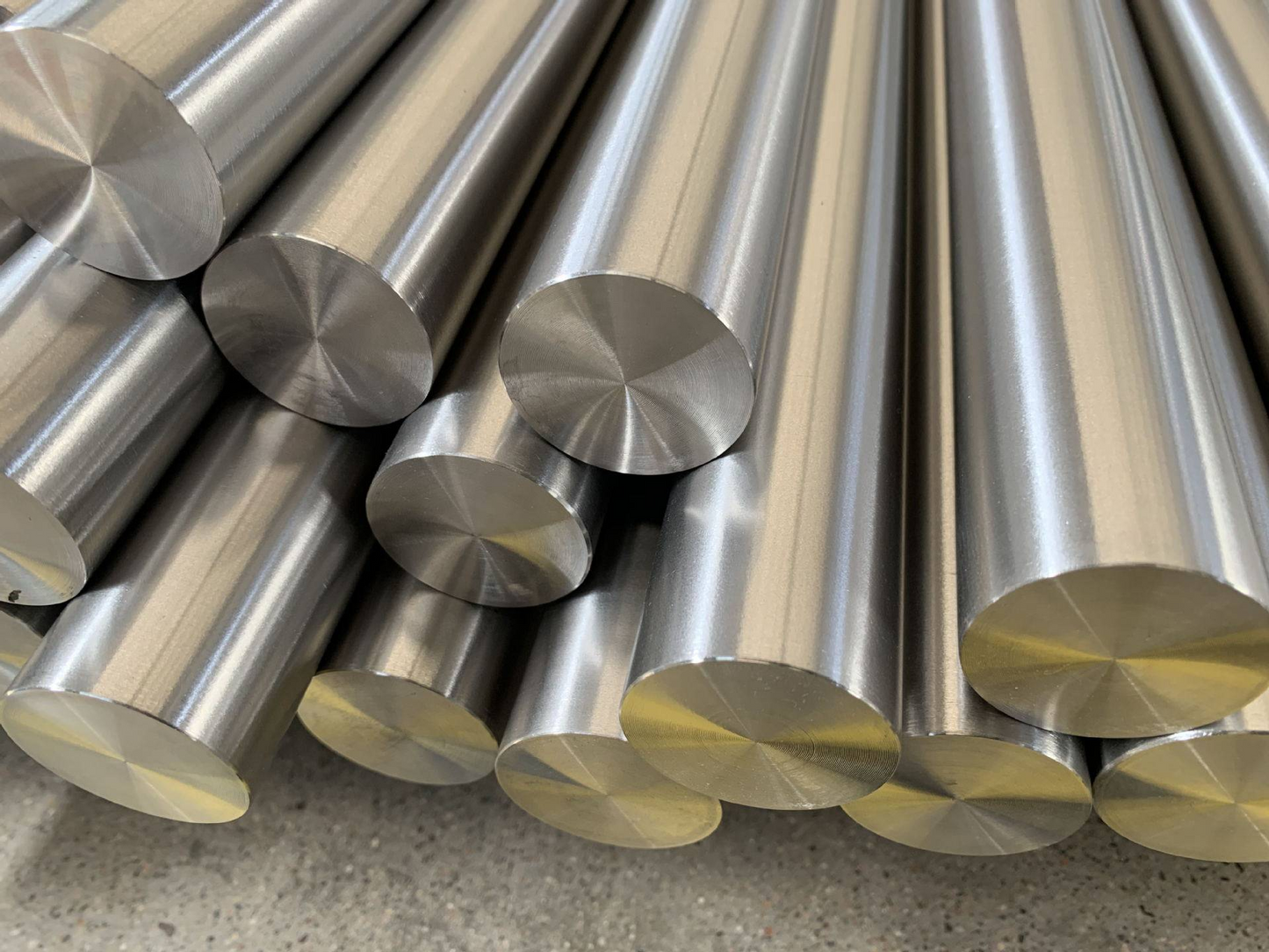

Product Overview

冶金特性

亜共晶鋼は、前共晶フェライトとパーライトコロニーからなる二相微細構造を示します。フェライト相は優れた延性と靭性を提供し、パーライトは強度と硬度に寄与します。共晶組成(0.77%)未満の炭素含有量は、強度と成形性の最適なバランスを確保し、荷重支持能力と加工の柔軟性を必要とする構造用途に理想的です。

熱処理プロセス

MetalZenithは、オーステナイト領域から850-900°Cでの制御冷却を行い、最適なフェライト-パーライト分布を達成します。私たちの正規化プロセスは、900-950°Cに加熱した後、空冷を行い、粒構造を精製し、機械的特性を改善します。重要な構造部品の寸法安定性を向上させるために、600-650°Cでの応力緩和アニーリングが適用される場合があります。

高度な製造プロセス

私たちの生産プロセスは、熱間圧延シーケンス全体での正確な温度監視を伴う制御圧延技術を取り入れています。MetalZenithの熱機械制御加工(TMCP)は、粒子の精製を最適化し、衝撃靭性を向上させながら、優れた溶接性を維持します。リアルタイムの微細構造監視により、一貫した品質と性能特性が保証されます。

専門的な品質テスト

包括的なテストプロトコルには、標準手順(SMAW、GMAW、SAW)を使用した溶接性能評価、成形性評価のための曲げ試験、耐久限界決定のための回転ビーム疲労試験、及び大気腐食抵抗のための塩水噴霧試験が含まれます。さまざまな温度でのシャルピーVノッチ衝撃試験は、多様な環境条件での信頼性のある性能を保証します。

応用工学の考慮事項

建設用には、私たちの亜共晶鋼は優れた耐震性と耐火性能を提供します。橋の用途は、優れた疲労抵抗と耐候性の特性から恩恵を受けます。機械製造用途は、材料の加工性と寸法安定性を活用します。自動車の構造部品は、鋼の衝突エネルギー吸収と成形能力を利用します。一般的な工学プロジェクトは、強度、延性、コスト効率の多様な組み合わせから恩恵を受けます。

🧪 Chemical Composition

| 元素 | 成分 (%) |

|---|---|

| 炭素 (C) | 0.25 - 0.75 |

| マンガン (Mn) | 0.60 - 1.65 |

| シリコン (Si) | 0.15 - 0.40 |

| リン (P) | ≤ 0.040 |

| 硫黄 (S) | ≤ 0.050 |

| 銅 (Cu) | 0.20 - 0.50 |

| クロム (Cr) | ≤ 0.30 |

| ニッケル (Ni) | ≤ 0.30 |

⚙️ Mechanical Properties

| 特性 | 値 |

|---|---|

| 降伏強度 (MPa) | 250 - 450 |

| 引張強度 (MPa) | 400 - 650 |

| 伸び (%) | ≥ 20 |

| 20°Cにおける衝撃エネルギー (J) | ≥ 27 |

| 硬度 (HB) | 120 - 200 |

| 疲労強度 (MPa) | 180 - 280 |

🔬 Physical Properties

| プロパティ | 値 |

|---|---|

| 密度 (g/cm3) | 7.85 |

| 融点 (°C) | 1450 - 1520 |

| 熱伝導率 (W/m·K) | 50.2 |

| 熱膨張 (×10??/K) | 11.8 |

| 弾性係数 (GPa) | 200 |

| ポアソン比 | 0.27 - 0.30 |

📏 Product Specifications

| 仕様 | 詳細 |

|---|---|

| 利用可能な形状 | プレート、シート、ビーム、アングル、チャンネル、バー |

| 厚さ範囲 | 3 - 150mm |

| 幅の範囲 | 1000 - 3500mm |

| 長さの範囲 | 6000 - 15000mm |

| 規格適合 | ASTM A36、ASTM A572、EN 10025 |

| 熱処理条件 | 熱間圧延、正規化、またはそのまま |

| 表面仕上げ | ミルスケール、ピックル、ショットブラスト |

あなたのプロジェクトの成功を共に創りましょう

プロフェッショナルチーム、プレミアム製品、完全なサービス - あなたのプロジェクトの成功は私たちの使命です

Our Advantages in Processing ハイポユーテクトイド鋼

制御されたロール技術

MetalZenithは、低過冷却鋼のフェライト-パーライト微細構造を最適化するために、正確な温度制御を伴う高度な制御圧延プロセスを利用しています。私たちの熱機械的処理は、材料の断面全体にわたって均一な粒径分布と強化された機械的特性を確保します。

包括的なパフォーマンステスト

私たちの品質保証プログラムには、構造用途に特化したテストが含まれています:溶接性能評価、成形性のための曲げ試験、回転ビーム疲労試験、および建設およびエンジニアリング環境での優れた性能を確保するための加速大気腐食試験。

カスタムファブリケーションサービス

MetalZenithは、切断、成形、溶接準備、熱処理最適化を含む包括的なカスタム加工サービスを提供しています。私たちの技術チームは、構造設計要件およびアプリケーション特有の材料変更に関する専門的なコンサルテーションを提供します。

あなたの信頼できる 鋼

製造パートナー

クイックお問い合わせ

私たちが提供する業界

主要産業向けのプロフェッショナルな鋼ソリューション

資格と認証