20年の経験 | 1000以上のブランドパートナー | 完全なカスタマイズ

私たちは20年の業界経験があり、1,000以上のブランドと提携し、あらゆるカスタマイズニーズをサポートしています。

Technical Specifications

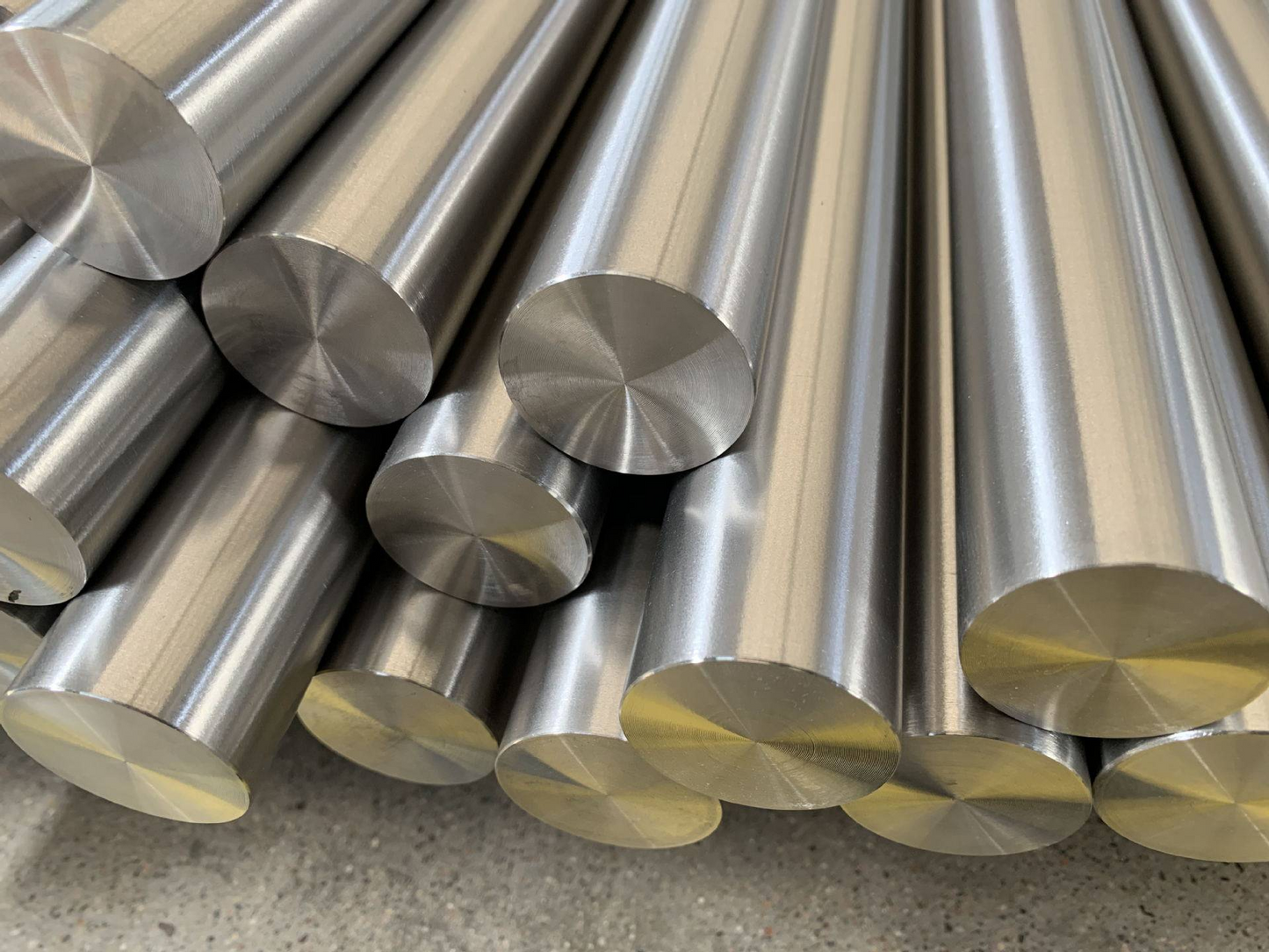

Product Overview

冶金特性

Elmaxは、細かく均一に分布したバナジウムおよびクロムカーバイドを持つマルテンサイト微細構造を示します。粉末冶金製造プロセスは、優れたカーバイド分布を確保し、従来の鋳造鋼に一般的な分離問題を排除します。これにより、荷重を支える用途に不可欠な優れた構造的完全性と予測可能な機械的特性が得られます。

熱処理プロセス

MetalZenithは、1030-1050°Cでの制御雰囲気硬化を行い、その後150-200°Cでの正確な焼戻しを行い、最適な強度と靭性のバランスを達成します。私たちのコンピュータ制御の熱処理は、断面全体で均一な特性を確保し、さまざまな荷重条件下での一貫した性能を必要とする構造用途にとって重要です。

製造プロセス

MetalZenithは、真空溶融、ガスアトマイズ、熱等方圧成形(HIP)を含む高度な粉末冶金技術を利用して、優れた清浄度と均一性を持つElmax鋼を製造します。私たちの制御された処理パラメータは、最適なカーバイドのサイズと分布を確保し、構造性能と信頼性を向上させます。

構造品質試験

包括的な試験プロトコルには、AWS D1.1基準に従った溶接性能評価、曲げ試験による成形能力評価、循環荷重条件下での疲労強度試験、さまざまな環境条件下での大気腐食抵抗試験が含まれます。これらの試験は、厳しい用途における長期的な構造的信頼性を確保します。

応用工学の考慮事項

建築工事や橋梁工学において、Elmaxは優れた強度対重量比を提供し、軽量な構造設計を可能にします。機械製造においては、その優れた疲労抵抗が動的荷重下での延長サービス寿命を確保します。車両製造においては、高強度と良好な成形性の組み合わせにより、構造的完全性を維持しながら複雑な構造ジオメトリを実現します。

🧪 Chemical Composition

| 元素 | 組成 (%) |

|---|---|

| 炭素 (C) | 1.70 |

| クロム (Cr) | 18.00 |

| バナジウム (V) | 3.00 |

| モリブデン (Mo) | 1.00 |

| マンガン (Mn) | 0.30 |

| シリコン (Si) | 0.80 |

| リン (P) | ≤ 0.030 |

| 硫黄 (S) | ≤ 0.030 |

⚙️ Mechanical Properties

| プロパティ | 値 |

|---|---|

| 降伏強度 (MPa) | ≥ 1900 |

| 引張強度 (MPa) | 2100 - 2300 |

| 伸び (%) | ≥ 8 |

| 20°Cでの衝撃エネルギー (J) | ≥ 25 |

| 硬度 (HRC) | 60 - 64 |

| 疲労強度 (MPa) | ≥ 850 |

🔬 Physical Properties

| プロパティ | 値 |

|---|---|

| 密度 (g/cm3) | 7.80 |

| 融点 (°C) | 1420 - 1460 |

| 熱伝導率 (W/m·K) | 20.5 |

| 熱膨張 (×10??/K) | 10.8 |

| 弾性係数 (GPa) | 210 |

| ポアソン比 | 0.27 - 0.30 |

📏 Product Specifications

| 仕様 | 詳細 |

|---|---|

| 利用可能な形状 | プレート、バー、ロッド、鍛造品、カスタム形状 |

| 厚さ範囲 | 10 - 200mm |

| 幅範囲 | 100 - 2000mm |

| 長さ範囲 | 1000 - 12000mm |

| 規格適合 | ASTM A514, AWS D1.1, EN 10025 |

| 熱処理条件 | 焼入れおよび焼戻し |

| 表面仕上げ | 熱間圧延、冷間仕上げ、機械加工 |

あなたのプロジェクトの成功を共に創りましょう

プロフェッショナルチーム、プレミアム製品、完全なサービス - あなたのプロジェクトの成功は私たちの使命です

Our Advantages in Processing エルマックス鋼

高度な粉末冶金処理

MetalZenithは、最適な炭化物分布と粒構造を達成するために、精密な温度制御と制御された雰囲気処理を用いた最先端の粉末冶金技術を採用しています。私たちの高度な製造プロセスは、材料の断面全体にわたって一貫した機械的特性と優れた構造的完全性を保証します。

包括的な構造テスト

MetalZenithは、構造用途向けに特別に設計された広範な試験プロトコルを実施しており、これには溶接性能評価、成形能力評価、繰り返し荷重下での疲労強度試験、及び大気腐食抵抗試験が含まれ、長期的な構造の信頼性を確保しています。

カスタム構造ソリューション

MetalZenithは、精密切断、カスタム熱処理スケジュール、特別な成形操作を含むカスタマイズされた加工サービスを提供しています。私たちの技術サポートチームは、構造エンジニアと密接に連携し、特定の耐荷重要件や環境条件に最適な材料特性を最適化します。

あなたの信頼できる 鋼

製造パートナー

クイックお問い合わせ

私たちが提供する業界

主要産業向けのプロフェッショナルな鋼ソリューション

資格と認証