20年の経験 | 1000以上のブランドパートナー | 完全なカスタマイズ

私たちは20年の業界経験があり、1,000以上のブランドと提携し、あらゆるカスタマイズニーズをサポートしています。

Technical Specifications

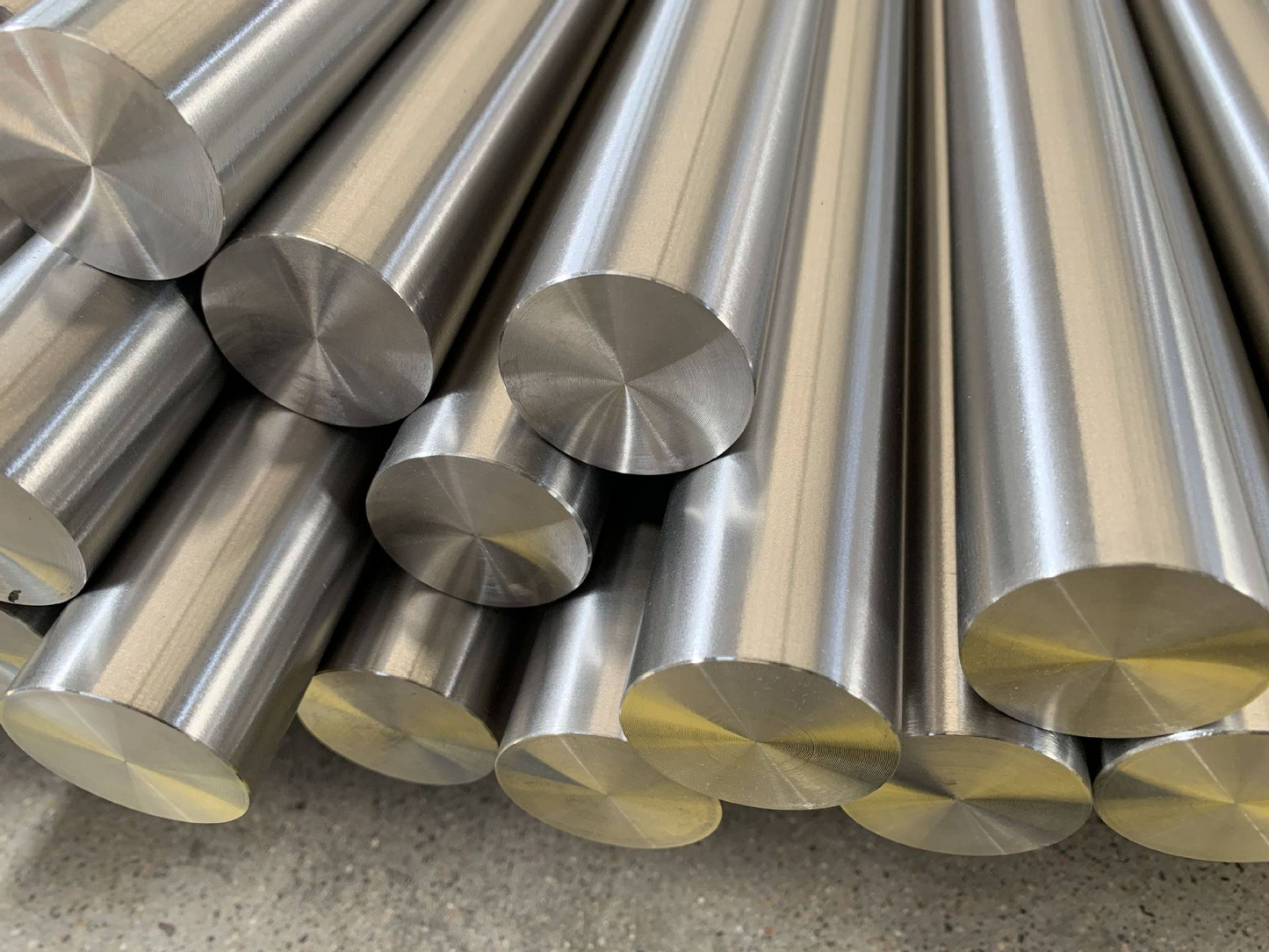

Product Overview

冶金特性

SCM415は、適切な熱処理後にテンパーされたマルテンサイト微細構造を示し、強度、靭性、および焼入れ性の優れた組み合わせを提供します。クロム含有量は焼入れ性を向上させ、中程度の耐腐食性を提供し、モリブデンの添加は高温強度を改善し、テンパーブリットルネスを低減します。制御された加工を通じて得られる微細な粒状構造は、均一な機械的特性と優れた疲労抵抗を確保します。

熱処理プロセス

MetalZenithは、SCM415のために慎重に制御された急冷およびテンパリングプロセスを採用しています。オーステナイト化は850-880°Cで行われ、その後油冷却を行い、完全なマルテンサイト変態を達成します。550-650°Cでのテンパリングは、強度と靭性の最適なバランスを発展させます。私たちのコンピュータ制御の炉は、均一な温度と冷却速度を確保し、一貫した機械的特性を提供します。

製造の卓越性

私たちの生産プロセスは、プレミアム原材料を使用した電気アーク炉の溶解から始まり、次に鋳型精製と真空脱ガスを行い、包含物を最小限に抑えます。連続鋳造と制御された圧延により、粒構造が最適化され、私たちの高度な熱処理設備は材料の断面全体にわたって均一な特性を確保します。

構造性能試験

MetalZenithは、構造用途に特化した包括的な試験を実施しています。これには、AWS D1.1基準に従った溶接性能評価、曲げ試験による成形能力評価、10^7サイクルまでの疲労強度試験、ASTM G50プロトコルに従った大気腐食抵抗試験が含まれます。これらの専門的な試験は、SCM415が構造工学用途の厳しい要件を満たすことを保証します。

応用工学の考慮事項

建物構造や橋梁工学において、SCM415の高い強度対重量比は、構造的完全性を維持しながら軽量設計を可能にします。機械製造においては、その優れた疲労抵抗と焼入れ性が高ストレス部品に最適です。車両製造においては、鋼の成形性と溶接性が複雑な形状を容易にし、衝突抵抗を提供します。一般的な工学用途において、SCM415の多様性は、特定の性能要件を満たすための多様な熱処理応答を可能にします。

🧪 Chemical Composition

| 元素 | 組成 (%) |

|---|---|

| 炭素 (C) | 0.13 - 0.18 |

| マンガン (Mn) | 0.60 - 0.85 |

| シリコン (Si) | 0.15 - 0.35 |

| リン (P) | ≤ 0.030 |

| 硫黄 (S) | ≤ 0.030 |

| クロム (Cr) | 0.90 - 1.20 |

| モリブデン (Mo) | 0.15 - 0.30 |

| ニッケル (Ni) | ≤ 0.25 |

⚙️ Mechanical Properties

| 特性 | 値 |

|---|---|

| 降伏強度 (MPa) | ≥ 835 |

| 引張強度 (MPa) | 980 - 1180 |

| 伸び (%) | ≥ 12 |

| 20°Cでの衝撃エネルギー (J) | ≥ 49 |

| 硬度 (HRC) | 30 - 37 |

| 疲労強度 (MPa) | ≥ 450 |

🔬 Physical Properties

| プロパティ | 値 |

|---|---|

| 密度 (g/cm3) | 7.85 |

| 融点 (°C) | 1480 - 1520 |

| 熱伝導率 (W/m·K) | 42.7 |

| 熱膨張 (×10??/K) | 12.3 |

| 弾性係数 (GPa) | 210 |

| ポアソン比 | 0.27 - 0.30 |

📏 Product Specifications

| 仕様 | 詳細 |

|---|---|

| 利用可能な形状 | 丸棒、角棒、平棒、プレート、鍛造品 |

| 直径範囲 | 10 - 300mm |

| 厚さ範囲 | 8 - 80mm |

| 長さ範囲 | 3000 - 12000mm |

| 規格適合 | JIS G4105、ASTM A29、DIN 1.7225 |

| 熱処理条件 | 焼入れおよび焼戻し |

| 表面仕上げ | 熱間圧延、冷間引抜き、機械加工 |

あなたのプロジェクトの成功を共に創りましょう

プロフェッショナルチーム、プレミアム製品、完全なサービス - あなたのプロジェクトの成功は私たちの使命です

Our Advantages in Processing SCM415

精密熱処理技術

MetalZenithは、SCM415の微細構造を最適化するために、コンピュータ制御の温度プロファイルを使用した高度な焼入れおよび焼戻しプロセスを利用しています。当社の最先端の熱処理設備は、材料の断面全体にわたって均一な硬度分布と優れた機械的特性を保証します。

包括的な構造性能試験

私たちの品質保証プログラムには、構造用途に特化したテストが含まれています:溶接性能評価、成形能力評価、10^7サイクルまでの疲労強度テスト、および大気腐食抵抗テスト。これらのテストは、SCM415が構造工学用途の厳しい要件を満たしていることを保証します。

カスタム処理およびエンジニアリングサポート

MetalZenithは、SCM415鋼のためにカスタマイズされた熱処理スケジュール、精密加工、およびカスタム成形サービスを提供します。当社の冶金エンジニアは、特定の構造設計要件を満たすための最適な材料選択と加工パラメータに関する技術コンサルテーションを提供します。

あなたの信頼できる 鋼

製造パートナー

クイックお問い合わせ

私たちが提供する業界

主要産業向けのプロフェッショナルな鋼ソリューション

資格と認証