20 Jahre Erfahrung | 1000+ Markenpartner | Vollständige Anpassung

Wir haben 20 Jahre Branchenerfahrung, haben mit über 1.000 Marken zusammengearbeitet und unterstützen alle Anpassungsbedürfnisse.

Technical Specifications

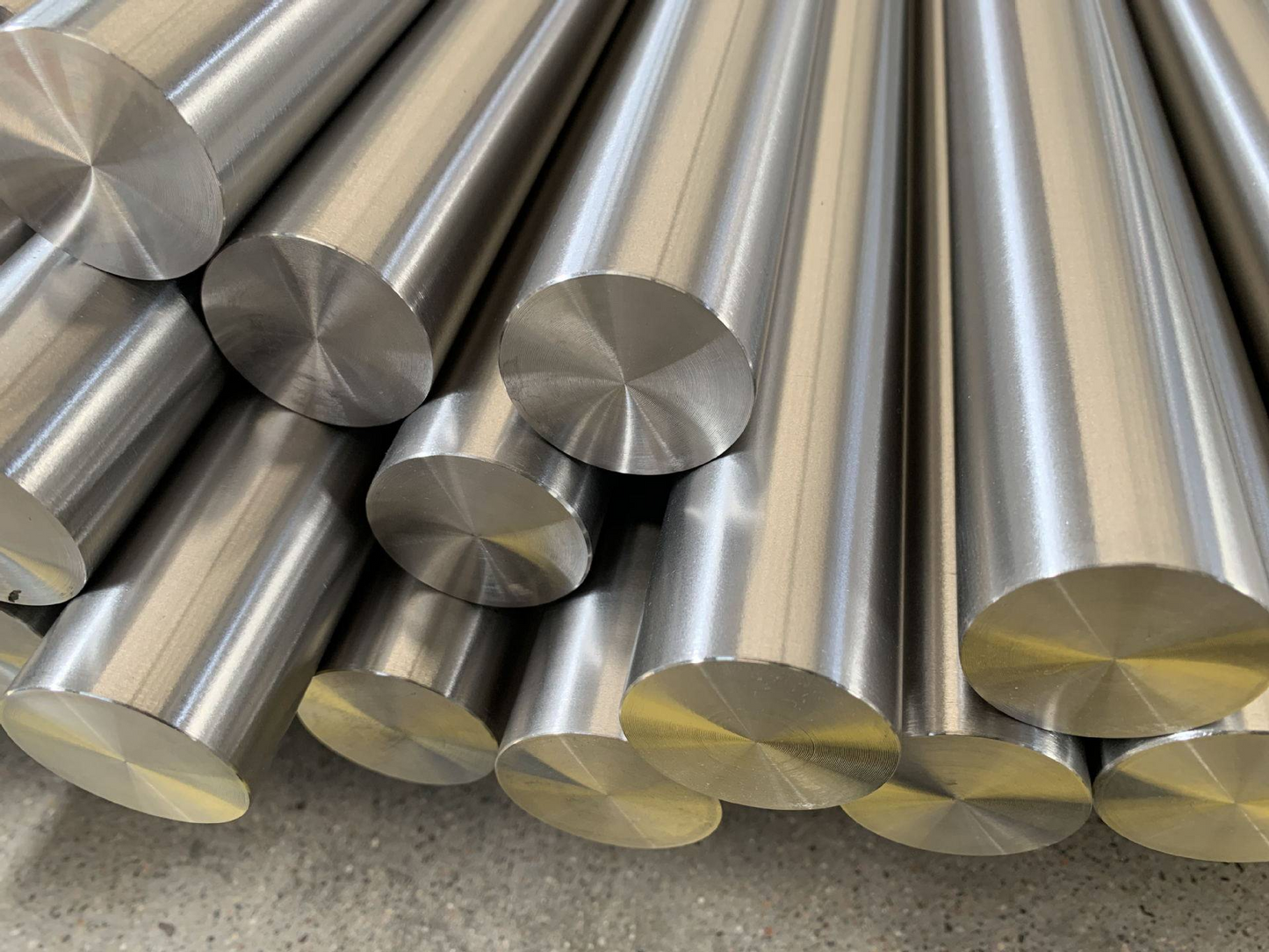

Product Overview

Metallurgische Eigenschaften

S500MC weist eine feinkörnige ferritische Mikrostruktur auf, die durch thermomechanisch kontrollierte Verarbeitung (TMCP) erreicht wird. Die kontrollierte Zugabe von Mikrolegierungselementen wie Niob, Vanadium und Titan fördert die Ausscheidungsstärkung und Kornverfeinerung, was zu außergewöhnlicher Festigkeit bei gleichzeitiger Beibehaltung überlegener Formbarkeit führt. Der niedrige Kohlenstoffgehalt gewährleistet eine ausgezeichnete Schweißbarkeit und verringert das Risiko von Kaltverzügen während der Verarbeitung.

Wärmebehandlungsprozess

MetalZenith setzt fortschrittliche TMCP-Technologie mit kontrollierten Walztemperaturen zwischen 850-950°C ein, gefolgt von beschleunigter Abkühlung, um optimale mechanische Eigenschaften zu erreichen. Der Prozess eliminiert die Notwendigkeit einer nachfolgenden Wärmebehandlung und gewährleistet gleichzeitig eine konsistente mikrostrukturelle Homogenität und verbesserte Formbarkeitseigenschaften, die für Kaltumformanwendungen unerlässlich sind.

Exzellenz im Herstellungsprozess

Unser hochmodernes Produktionswerk nutzt computergesteuerte Walzwerke mit Echtzeit-Temperaturüberwachung und präziser Dehnungsregelung. MetalZeniths fortschrittliche Prozesskontrolle gewährleistet konsistente mechanische Eigenschaften über die Materialdicke und -länge hinweg und liefert überlegene Qualität für anspruchsvolle Struktur-Anwendungen, die sowohl Festigkeit als auch Formbarkeit erfordern.

Spezialisierte Qualitätsprüfung

MetalZenith führt umfassende Testprotokolle durch, einschließlich fortschrittlicher Schweißbarkeitsbewertungen unter Verwendung standardisierter Verfahren, Simulationstests zur Kaltumformung zur Bewertung der Biegbarkeit und Dehnfließfähigkeit, Ermüdungsfestigkeitsbewertungen unter zyklischen Belastungsbedingungen und beschleunigte Tests zur atmosphärischen Korrosionsbeständigkeit. Diese spezialisierten Tests gewährleisten optimale Leistung in strukturellen Anwendungen.

Anwendungsspezifische technische Überlegungen

Für den Bau von Strukturen und Brückenbau bietet S500MC hervorragende Festigkeits-Gewichts-Verhältnisse, die leichtere Designs ermöglichen, ohne die strukturelle Integrität zu beeinträchtigen. In der Maschinenbau- und Fahrzeugkonstruktion ermöglicht die überlegene Formbarkeit komplexe Geometrien bei gleichzeitiger Beibehaltung hoher Festigkeit. Die ausgezeichnete Schweißbarkeit und der niedrige Kohlenstoffäquivalent gewährleisten zuverlässige Verbindungen in allgemeinen Ingenieuranwendungen, was es ideal für gefertigte Strukturen macht, die sowohl Leistung als auch Kosteneffizienz erfordern.

🧪 Chemical Composition

| Element | Zusammensetzung (%) |

|---|---|

| Kohlenstoff (C) | ≤ 0.12 |

| Mangan (Mn) | ≤ 1.60 |

| Silizium (Si) | ≤ 0.50 |

| Phosphor (P) | ≤ 0.025 |

| Schwefel (S) | ≤ 0.015 |

| Aluminium (Al) | ≥ 0.015 |

| Niob (Nb) | ≤ 0.09 |

| Vanadium (V) | ≤ 0.20 |

| Titan (Ti) | ≤ 0.15 |

⚙️ Mechanical Properties

| Eigenschaft | Wert |

|---|---|

| Streckgrenze (MPa) | ≥ 500 |

| Zugfestigkeit (MPa) | 550 - 700 |

| Dehnung (%) | ≥ 19 |

| Schlagenergie bei -20°C (J) | ≥ 27 |

| Härte (HV) | 160 - 220 |

| Biegeprüfung (r/t) | ≤ 2.0 |

🔬 Physical Properties

| Eigenschaft | Wert |

|---|---|

| Dichte (g/cm3) | 7.85 |

| Schmelzpunkt (°C) | 1510 - 1540 |

| Wärmeleitfähigkeit (W/m·K) | 49.8 |

| Wärmeausdehnung (×10??/K) | 11.5 |

| Elastizitätsmodul (GPa) | 210 |

| Poisson-Zahl | 0.30 |

📏 Product Specifications

| Spezifikation | Details |

|---|---|

| Verfügbare Formen | Warmgewalzte Bleche, Kaltgewalzte Bleche, Coils, Platten |

| Dickenbereich | 1,5 - 12,0 mm |

| Breitenbereich | 1000 - 2100 mm |

| Längenbereich | 2000 - 12000 mm |

| Einhaltung von Standards | EN 10149-2, ASTM A1011 HSLAS Grad 50 |

| Oberflächenzustand | Warmgewalzt, Entzundert & Geölt, Kaltgewalzt |

| Kantenzustand | Walzkante, Schnittkante, Beschnittene Kante |

Lassen Sie uns Erfolg für Ihr Projekt schaffen

Professionelles Team, Premium-Produkte, Vollständiger Service - Ihr Projekterfolg ist unsere Mission

Our Advantages in Processing S500MC Stahl

Fortgeschrittene TMCP-Verarbeitungstechnologie

MetalZenith nutzt modernste thermomechanische Kontrollverarbeitung (TMCP) mit präziser Temperaturkontrolle und optimierten Walzplänen, um eine überlegene Kornverfeinerung im S500MC-Stahl zu erreichen. Unsere fortschrittliche Verarbeitung gewährleistet außergewöhnliche Festigkeits-Gewichts-Verhältnisse und gleichzeitig eine herausragende Kaltumformbarkeit, die für komplexe Struktur-Anwendungen unerlässlich ist.

Umfassende strukturelle Leistungsprüfung

MetalZenith führt umfassende Testprotokolle durch, die speziell für strukturelle Anwendungen entwickelt wurden, einschließlich fortschrittlicher Schweißbarkeitsbewertungen, Simulationstests zur Kaltumformung, Bewertung der Ermüdungsfestigkeit unter zyklischer Belastung und Tests zur Beständigkeit gegen atmosphärische Korrosion. Unsere Qualitätssicherung gewährleistet optimale Leistung in Bauwerken, Brückenbau und Anwendungen in der Schwerindustrie.

Benutzerdefinierte Verarbeitung und Ingenieurdienstleistungen

MetalZenith bietet umfassende maßgeschneiderte Bearbeitungsdienste an, einschließlich präziser Schneid-, Form- und Wärmebehandlungsoptimierung, die auf spezifische strukturelle Anforderungen zugeschnitten sind. Unser technisches Team bietet fachkundige Ingenieurdienstleistungen für komplexe Projekte und gewährleistet die optimale Materialauswahl und Bearbeitungsparameter für anspruchsvolle Bau- und Fertigungsanwendungen.

IHR VERTRAUENwürdiger STAHL

HERSTELLUNGSPARTNER

Schnellanfrage

Branchen, die wir bedienen

Professionelle Stahl-Lösungen in wichtigen Branchen

Qualifikationen & Zertifizierungen