20 Jahre Erfahrung | 1000+ Markenpartner | Vollständige Anpassung

Wir haben 20 Jahre Branchenerfahrung, haben mit über 1.000 Marken zusammengearbeitet und unterstützen alle Anpassungsbedürfnisse.

Technical Specifications

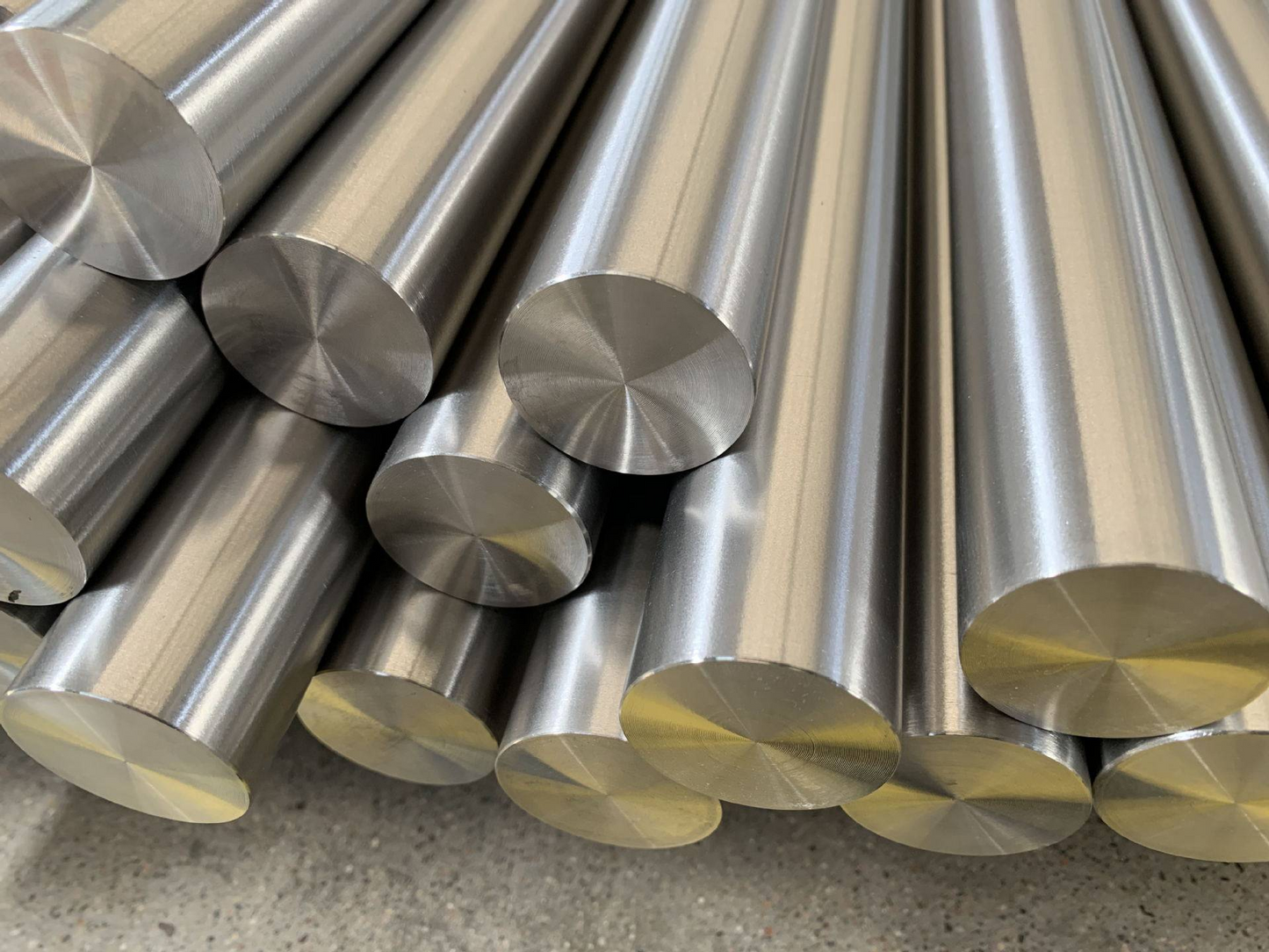

Product Overview

Metallurgische Eigenschaften

T45 ist ein niedriglegierter hochfester Baustahl mit einer vergüteten martensitischen Mikrostruktur, die außergewöhnliche Festigkeit und Zähigkeit bietet. Die kontrollierte Zugabe von Chrom, Molybdän und Nickel verbessert die Härtbarkeit und bietet überlegene mechanische Eigenschaften im Vergleich zu herkömmlichen Kohlenstoffstählen. Die feinkörnige Struktur, die durch kontrollierte Verarbeitung erreicht wird, gewährleistet eine hervorragende Schlagfestigkeit und Ermüdungsbeständigkeit.

Wärmebehandlungsprozess

MetalZenith verwendet präzise Abschreck- und Vergütungsprozesse mit Austenitisierung bei 850-900°C, gefolgt von kontrollierter Abkühlung und Vergütung bei 580-650°C. Dieser Wärmebehandlungszyklus optimiert das Gleichgewicht zwischen Festigkeit und Zähigkeit und gewährleistet gleichzeitig dimensionsstabile Eigenschaften und Spannungsabbau für strukturelle Anwendungen.

Fertigungsexzellenz

Unser fortschrittlicher Fertigungsprozess umfasst das Schmelzen im Lichtbogenofen, die Pfannenverfeinerung und das kontinuierliche Gießen, gefolgt von kontrolliertem Walzen. Die Echtzeitüberwachung von Temperatur- und Verformungsparametern gewährleistet konsistente mechanische Eigenschaften und mikrostrukturelle Homogenität im gesamten Materialquerschnitt.

Strukturelle Leistungstests

Der T45-Stahl unterliegt umfassenden Tests, einschließlich Schweißbarkeitseinschätzungen mit standardisierten Verfahren, Bewertung der Formbarkeit durch Biegetests, Ermüdungsfestigkeitstests unter zyklischen Belastungsbedingungen und Bewertung der atmosphärischen Korrosionsbeständigkeit. Diese spezialisierten Tests gewährleisten eine optimale Leistung in anspruchsvollen strukturellen Umgebungen, in denen langfristige Zuverlässigkeit entscheidend ist.

Anwendungsengineering

Für Anwendungen im Bauwesen bietet T45 hervorragende Festigkeits-Gewichts-Verhältnisse, die leichtere Strukturdesigns ermöglichen. Im Brückenbau gewährleistet die überlegene Ermüdungsbeständigkeit eine lange Lebensdauer unter dynamischer Belastung. Für die Maschinenbauindustrie erleichtert die Kombination aus hoher Festigkeit und guter Bearbeitbarkeit eine effiziente Fertigung. In der Fahrzeugproduktion ermöglichen die hervorragenden Formeigenschaften komplexe Bauteilgeometrien, während die strukturelle Integrität gewahrt bleibt.

🧪 Chemical Composition

| Element | Zusammensetzung (%) |

|---|---|

| Kohlenstoff (C) | 0.20 - 0.25 |

| Mangan (Mn) | 1.20 - 1.60 |

| Silizium (Si) | 0.15 - 0.40 |

| Phosphor (P) | ≤ 0.030 |

| Schwefel (S) | ≤ 0.030 |

| Chrom (Cr) | 0.80 - 1.10 |

| Molybdän (Mo) | 0.15 - 0.25 |

| Nickel (Ni) | 0.30 - 0.70 |

⚙️ Mechanical Properties

| Eigenschaft | Wert |

|---|---|

| Streckgrenze (MPa) | ≥ 450 |

| Zugfestigkeit (MPa) | 630 - 780 |

| Dehnung (%) | ≥ 18 |

| Schlagenergie bei 20°C (J) | ≥ 35 |

| Härte (HB) | 180 - 230 |

| Wechselfestigkeit (MPa) | 280 - 320 |

🔬 Physical Properties

| Eigenschaft | Wert |

|---|---|

| Dichte (g/cm3) | 7.85 |

| Schmelzpunkt (°C) | 1480 - 1520 |

| Wärmeleitfähigkeit (W/m·K) | 42.5 |

| Wärmeausdehnung (×10??/K) | 11.8 |

| Elastizitätsmodul (GPa) | 210 |

| Poisson-Zahl | 0.27 - 0.30 |

📏 Product Specifications

| Spezifikation | Einzelheiten |

|---|---|

| Verfügbare Formen | Platten, Träger, Kanäle, Winkel, Stangen, Schmiedeteile |

| Dickenbereich | 8 - 150mm |

| Breitenbereich | 1200 - 3500mm |

| Längenbereich | 6000 - 15000mm |

| Einhaltung von Standards | ASTM A572, EN 10025-6, JIS G3106 |

| Wärmebehandlungszustand | Normalisiert oder Vergütet |

| Oberflächenfinish | Warmgewalzt, Entzundert, Strahlgebläßt |

Lassen Sie uns Erfolg für Ihr Projekt schaffen

Professionelles Team, Premium-Produkte, Vollständiger Service - Ihr Projekterfolg ist unsere Mission

Our Advantages in Processing T45 Stahl

Fortgeschrittene thermomechanische Verarbeitung

MetalZenith nutzt kontrolliertes Walzen mit präziser Temperaturüberwachung und optimierten Normalisierungszyklen, um eine überlegene Kornstruktur und verbesserte mechanische Eigenschaften zu erreichen. Unsere fortschrittliche Verarbeitung gewährleistet eine konsistente Festigkeit und Zähigkeit über den gesamten Querschnitt des Materials, was für strukturelle Anwendungen entscheidend ist.

Umfassende strukturelle Tests

Unser T45-Stahl unterliegt umfangreichen Tests, einschließlich Schweißbarkeitseinschätzungen, Bewertung der Formbarkeit, Analyse der Ermüdungsfestigkeit und Tests zur Beständigkeit gegen atmosphärische Korrosion. Diese umfassende Qualitätssicherung gewährleistet eine optimale Leistung in anspruchsvollen strukturellen Umgebungen.

Maßgeschneiderte Fertigungsdienste

MetalZenith bietet umfassende maßgeschneiderte Bearbeitungsdienste an, einschließlich präziser Schneid-, Form-, Schweißvorbereitungs- und Wärmebehandlungsmodifikationen. Unser technisches Support-Team arbeitet eng mit Bauingenieuren zusammen, um die Materialanforderungen für spezifische Bau- und Ingenieuranforderungen zu optimieren.

IHR VERTRAUENwürdiger STAHL

HERSTELLUNGSPARTNER

Schnellanfrage

Branchen, die wir bedienen

Professionelle Stahl-Lösungen in wichtigen Branchen

Qualifikationen & Zertifizierungen