20 Jahre Erfahrung | 1000+ Markenpartner | Vollständige Anpassung

Wir haben 20 Jahre Branchenerfahrung, haben mit über 1.000 Marken zusammengearbeitet und unterstützen alle Anpassungsbedürfnisse.

Technical Specifications

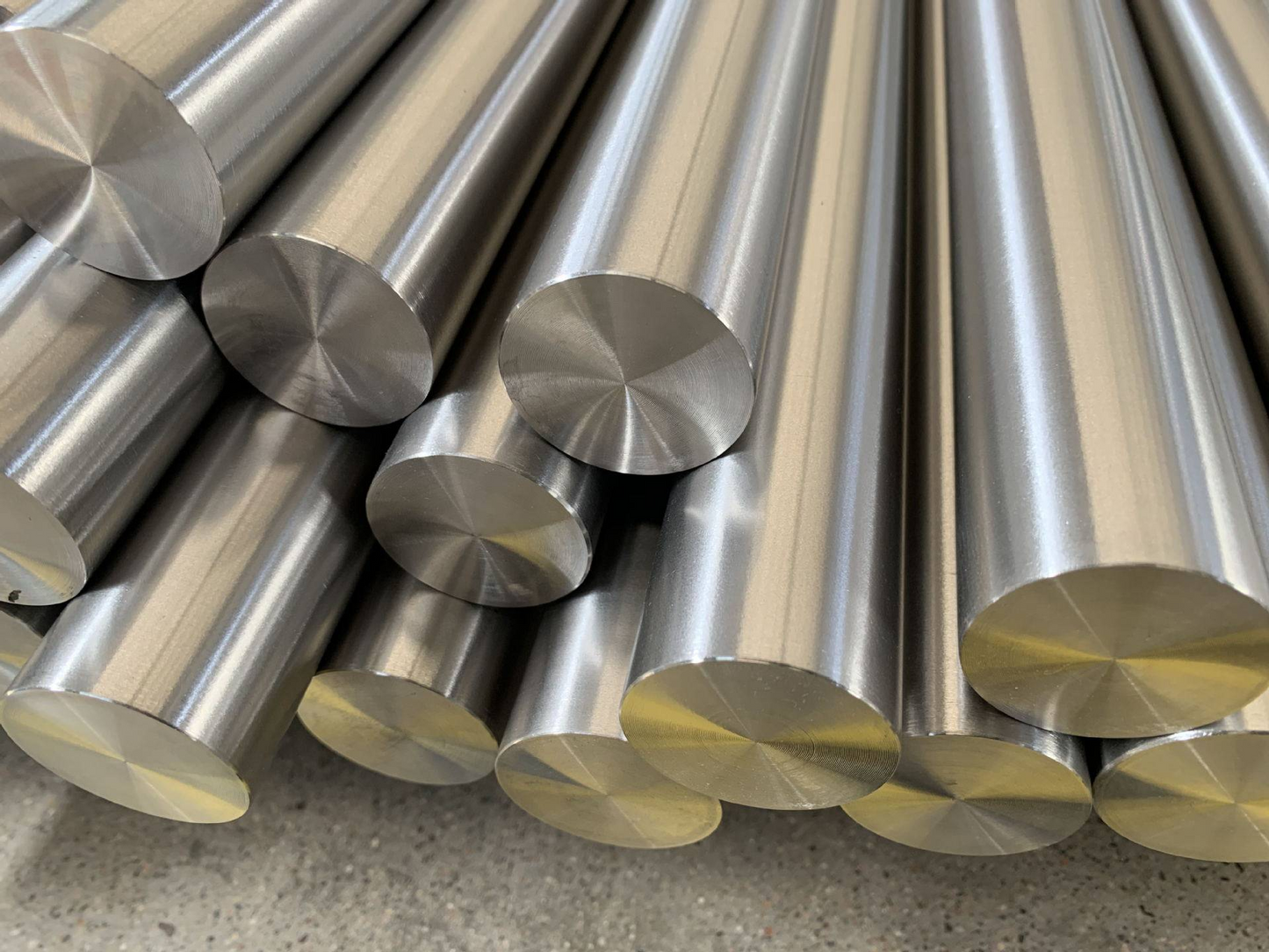

Product Overview

Metallurgische Eigenschaften

S136 ist ein vergüteter und gehärteter legierter Baustahl mit einer feinkörnigen martensitischen Mikrostruktur und temperierten Karbidausfällungen. Die kontrollierte Zugabe von Chrom, Molybdän und Nickel sorgt für eine verbesserte Härtbarkeit und verbesserte mechanische Eigenschaften. Der optimierte Kohlenstoffgehalt gewährleistet ein ausgezeichnetes Verhältnis von Festigkeit zu Gewicht und erhält gleichzeitig eine gute Schweißbarkeit für strukturelle Anwendungen.

Wärmebehandlungsprozess

MetalZenith verwendet präzises Abschrecken von 850-900°C, gefolgt von einer Temperierung bei 580-620°C, um optimale mechanische Eigenschaften im S136-Stahl zu erreichen. Unsere kontrollierten Abkühlraten und Temperaturüberwachung gewährleisten eine gleichmäßige Härteverteilung und Spannungsabbau, was für die strukturelle Integrität in anspruchsvollen Anwendungen entscheidend ist.

Herstellungsprozess

Unsere S136-Produktion nutzt das Schmelzen im Lichtbogenofen mit sekundären Raffinationsprozessen, einschließlich der Behandlung im Pfannenofen und Vakuumentgasung. Die kontinuierliche Gieß- und kontrollierte Walztechnologie von MetalZenith gewährleistet außergewöhnliche Sauberkeit und einheitliche mechanische Eigenschaften im gesamten Materialquerschnitt.

Spezialisierte Qualitätsprüfung

S136-Stahl unterliegt umfassenden Tests, einschließlich der Bewertung der Schweißbarkeit gemäß AWS-Standards, der Bewertung der Umformleistung, der Ermüdungsfestigkeitsprüfung unter zyklischer Belastung und der Analyse der atmosphärischen Korrosionsbeständigkeit. Unsere Qualitätskontrolle umfasst Ultraschallinspektion, Makro-Ätztests und Kornanalyse, um die strukturelle Zuverlässigkeit sicherzustellen.

Überlegungen zu strukturellen Anwendungen

Für den Bau bietet S136 eine hervorragende Tragfähigkeit mit überlegener Erdbebenresistenz. Im Brückenbau gewährleisten die Ermüdungsfestigkeit und die atmosphärische Korrosionsbeständigkeit des Materials eine langfristige Haltbarkeit. Für die Maschinenbauindustrie ermöglicht die Kombination aus hoher Festigkeit und guter Bearbeitbarkeit komplexe Strukturkomponenten. In der Fahrzeugherstellung bietet S136 ein optimales Verhältnis von Festigkeit zu Gewicht für Chassis- und Rahmenanwendungen, während der allgemeine Maschinenbau von seinen vielseitigen Umform- und Schweißeigenschaften profitiert.

🧪 Chemical Composition

| Element | Zusammensetzung (%) |

|---|---|

| Kohlenstoff (C) | 0.35 - 0.42 |

| Mangan (Mn) | 1.35 - 1.65 |

| Silizium (Si) | 0.80 - 1.20 |

| Chrom (Cr) | 1.00 - 1.50 |

| Molybdän (Mo) | 0.15 - 0.30 |

| Phosphor (P) | ≤ 0.030 |

| Schwefel (S) | ≤ 0.030 |

| Nickel (Ni) | 0.25 - 0.45 |

⚙️ Mechanical Properties

| Eigenschaft | Wert |

|---|---|

| Streckgrenze (MPa) | 1030 - 1180 |

| Zugfestigkeit (MPa) | 1150 - 1300 |

| Dehnung (%) | ≥ 12 |

| Schlagenergie bei 20°C (J) | ≥ 35 |

| Härte (HRC) | 36 - 40 |

| Wechselfestigkeit (MPa) | 450 - 520 |

🔬 Physical Properties

| Eigenschaft | Wert |

|---|---|

| Dichte (g/cm3) | 7.80 |

| Schmelzpunkt (°C) | 1420 - 1460 |

| Wärmeleitfähigkeit (W/m·K) | 42.5 |

| Wärmeausdehnung (×10??/K) | 11.8 |

| Elastizitätsmodul (GPa) | 210 |

| Poisson-Zahl | 0.28 |

📏 Product Specifications

| Spezifikation | Details |

|---|---|

| Verfügbare Formen | Platten, Bleche, Stangen, Träger, Profile, Winkel |

| Dickenbereich | 3 - 200mm |

| Breitenbereich | 1000 - 3000mm |

| Längenbereich | 6000 - 12000mm |

| Einhaltung von Standards | ASTM A514, EN 10025, JIS G3106 |

| Wärmebehandlungszustand | Abgeschreckt und Anlassen |

| Oberflächenfinish | Warmgewalzt, Entzundert, Strahlgebläßt |

Lassen Sie uns Erfolg für Ihr Projekt schaffen

Professionelles Team, Premium-Produkte, Vollständiger Service - Ihr Projekterfolg ist unsere Mission

Our Advantages in Processing S136 Stahl

Fortgeschrittene thermomechanische Verarbeitung

MetalZenith nutzt kontrollierte Walztechnologie mit präziser Temperaturkontrolle und optimierten Abkühlraten, um eine überlegene Kornverfeinerung im S136-Stahl zu erreichen. Unser fortschrittlicher Prozess gewährleistet konsistente mechanische Eigenschaften über die gesamte Materialdicke hinweg und verbessert die strukturelle Integrität sowie die Schweißbarkeit für kritische Bauanwendungen.

Umfassende strukturelle Tests

Unser S136-Stahl unterliegt umfangreichen Testprotokollen, einschließlich der Bewertung der Schweißbarkeit, der Bewertung der Formbarkeit, der Prüfung der Ermüdungsfestigkeit und der Analyse der atmosphärischen Korrosionsbeständigkeit. Die Qualitätssicherung von MetalZenith gewährleistet eine optimale Leistung in strukturellen Anwendungen mit verifiziertem Schlagzähigkeit und langfristiger Haltbarkeit.

Maßgeschneiderte Struktur Lösungen

MetalZenith bietet umfassende Anpassungsdienste für S136-Stahl, einschließlich präziser Schneid-, Form-, Schweißvorbereitungs- und Oberflächenbehandlungsdienste. Unser technisches Team bietet fachkundige Beratung zur Optimierung des strukturellen Designs und zur Materialauswahl, um eine optimale Leistung in Bau-, Brücken- und Maschinenanwendungen zu gewährleisten.

IHR VERTRAUENwürdiger STAHL

HERSTELLUNGSPARTNER

Schnellanfrage

Branchen, die wir bedienen

Professionelle Stahl-Lösungen in wichtigen Branchen

Qualifikationen & Zertifizierungen