20 Jahre Erfahrung | 1000+ Markenpartner | Vollständige Anpassung

Wir haben 20 Jahre Branchenerfahrung, haben mit über 1.000 Marken zusammengearbeitet und unterstützen alle Anpassungsbedürfnisse.

Technical Specifications

Product Overview

Metallurgische Eigenschaften

Q345-Stahl weist eine feinkörnige ferritisch-perlitische Mikrostruktur auf, die durch kontrolliertes Walzen und optimierte chemische Zusammensetzung erreicht wird. Der ausgewogene Kohlenstoff- und Mangangehalt, kombiniert mit Mikrolegierungselementen, bietet ein hervorragendes Verhältnis von Festigkeit zu Gewicht und überlegene Schweißbarkeit, die für strukturelle Anwendungen unerlässlich sind.

Wärmebehandlungsprozess

MetalZenith verwendet kontrolliertes Walzen bei Temperaturen zwischen 850-950°C, gefolgt von kontrollierter Abkühlung, um optimale mechanische Eigenschaften zu erreichen. Unser thermomechanisch kontrollierter Prozess (TMCP) gewährleistet eine Kornverfeinerung und verbesserte Zähigkeit, während eine hervorragende Formbarkeit für die strukturelle Fertigung erhalten bleibt.

Exzellenz im Fertigungsprozess

Unsere Q345-Produktion nutzt fortschrittliche Lichtbogenofen-Technologie mit präziser Kontrolle der chemischen Zusammensetzung, gefolgt von kontinuierlichem Gießen und kontrolliertem Walzen. Echtzeit-Überwachungssysteme gewährleisten eine konsistente Qualität und mechanische Eigenschaften während des gesamten Produktionsprozesses und erfüllen strenge Anforderungen an Baustahl.

Strukturelle Leistungstests

MetalZenith führt umfassende Testprotokolle durch, die spezifisch für strukturelle Anwendungen sind, einschließlich der Bewertung der Schweißleistung unter Verwendung standardisierter Verfahren, der Bewertung der Kaltumformfähigkeit, der Ermüdungsfestigkeitsprüfung unter zyklischen Belastungsbedingungen und der Prüfung der atmosphärischen Korrosionsbeständigkeit, um die langfristige Haltbarkeit in Bauumgebungen sicherzustellen.

Anwendungsingenieurtechnische Überlegungen

Für den Bau von Gebäuden und Hochhausanwendungen bietet Q345 optimale Verhältnisse von Festigkeit zu Gewicht und hervorragende Schweißbarkeit für komplexe Verbindungsgeometrien. Im Brückenbau gewährleisten die überlegene Ermüdungsbeständigkeit und die Eigenschaften der atmosphärischen Korrosion des Stahls die langfristige strukturelle Integrität. Für die Maschinenbau- und Automobilanwendungen ermöglichen die hervorragende Formbarkeit und die konsistenten mechanischen Eigenschaften eine effiziente Fertigung komplexer Strukturkomponenten.

🧪 Chemical Composition

| Element | Zusammensetzung (%) |

|---|---|

| Kohlenstoff (C) | ≤ 0.20 |

| Mangan (Mn) | 1.00 - 1.60 |

| Silizium (Si) | 0.20 - 0.55 |

| Phosphor (P) | ≤ 0.035 |

| Schwefel (S) | ≤ 0.035 |

| Chrom (Cr) | ≤ 0.30 |

| Nickel (Ni) | ≤ 0.50 |

| Kupfer (Cu) | ≤ 0.30 |

⚙️ Mechanical Properties

| Eigenschaft | Wert |

|---|---|

| Streckgrenze (MPa) | ≥ 345 |

| Zugfestigkeit (MPa) | 470 - 630 |

| Dehnung (%) | ≥ 21 |

| Schlagenergie bei 20°C (J) | ≥ 34 |

| Härte (HB) | ≤ 229 |

| Ermüdungsfestigkeit (MPa) | 160 - 180 |

🔬 Physical Properties

| Eigenschaft | Wert |

|---|---|

| Dichte (g/cm3) | 7.85 |

| Schmelzpunkt (°C) | 1500 - 1540 |

| Wärmeleitfähigkeit (W/m·K) | 51.9 |

| Wärmeausdehnung (×10??/K) | 12.5 |

| Elastizitätsmodul (GPa) | 206 |

| Poisson-Zahl | 0.26 |

📏 Product Specifications

| Spezifikation | Details |

|---|---|

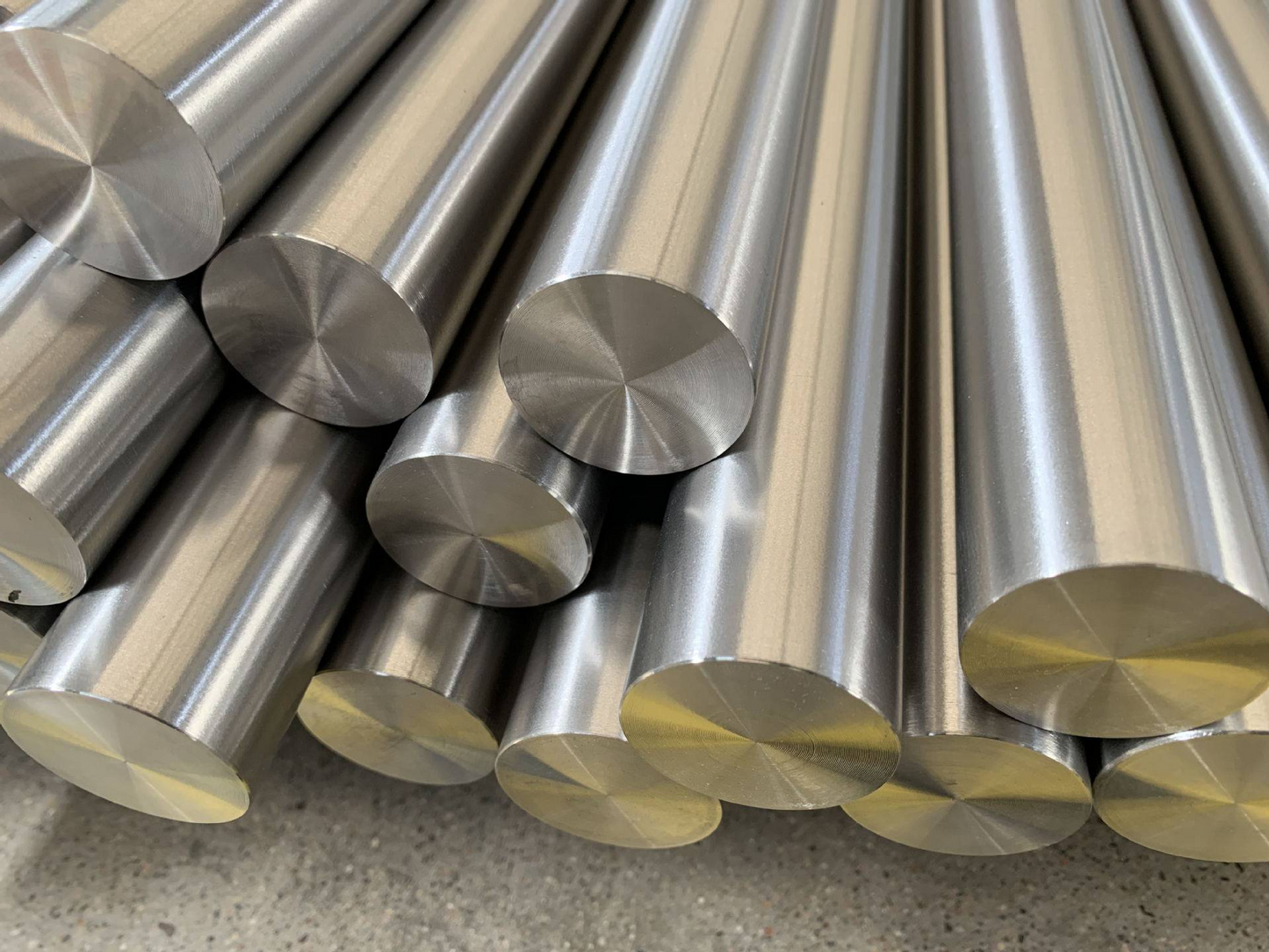

| Verfügbare Formen | Platten, Bleche, Träger, Kanäle, Winkel, Stangen |

| Dickenbereich | 3 - 150mm |

| Breitenbereich | 1000 - 4200mm |

| Längenbereich | 6000 - 18000mm |

| Einhaltung von Standards | GB/T 1591, ASTM A572, EN 10025-2 |

| Wärmebehandlungszustand | Warmgewalzt, Normalisiert, TMCP |

| Oberflächenfinish | Walzhaut, Strahlgebläßt, Beizend |

Lassen Sie uns Erfolg für Ihr Projekt schaffen

Professionelles Team, Premium-Produkte, Vollständiger Service - Ihr Projekterfolg ist unsere Mission

Our Advantages in Processing Q345 Stahl

Fortgeschrittene kontrollierte Walztechnologie

MetalZenith nutzt hochmoderne kontrollierte Walzprozesse mit präziser Temperaturkontrolle und optimierten Reduktionsplänen, um eine überlegene Kornverfeinerung im Q345-Stahl zu erreichen. Unser fortschrittliches thermomechanisches Verfahren gewährleistet konsistente mechanische Eigenschaften und verbesserte strukturelle Leistung über den gesamten Querschnitt des Materials.

Umfassende strukturelle Leistungsprüfung

Unser Q345-Stahl unterliegt umfangreichen Testprotokollen, einschließlich der Bewertung der Schweißleistung, der Beurteilung der Kaltumformfähigkeit, der Ermüdungsfestigkeitsprüfung unter zyklischer Belastung und der Prüfung der atmosphärischen Korrosionsbeständigkeit. Diese umfassenden Tests gewährleisten eine optimale Leistung in anspruchsvollen strukturellen Anwendungen.

Maßgeschneiderte Fertigung und Ingenieurdienstleistungen

MetalZenith bietet umfassende maßgeschneiderte Bearbeitungsdienste, einschließlich präziser Schneid-, Form-, Schweißvorbereitung und Oberflächenbehandlung. Unser technisches Team bietet umfassende Ingenieurdienstleistungen zur Optimierung des strukturellen Designs und zur materialgerechten Auswahl für spezifische Anwendungen, um den einzigartigen Projektanforderungen gerecht zu werden.

IHR VERTRAUENwürdiger STAHL

HERSTELLUNGSPARTNER

Schnellanfrage

Branchen, die wir bedienen

Professionelle Stahl-Lösungen in wichtigen Branchen

Qualifikationen & Zertifizierungen