20 Jahre Erfahrung | 1000+ Markenpartner | Vollständige Anpassung

Wir haben 20 Jahre Branchenerfahrung, haben mit über 1.000 Marken zusammengearbeitet und unterstützen alle Anpassungsbedürfnisse.

Technical Specifications

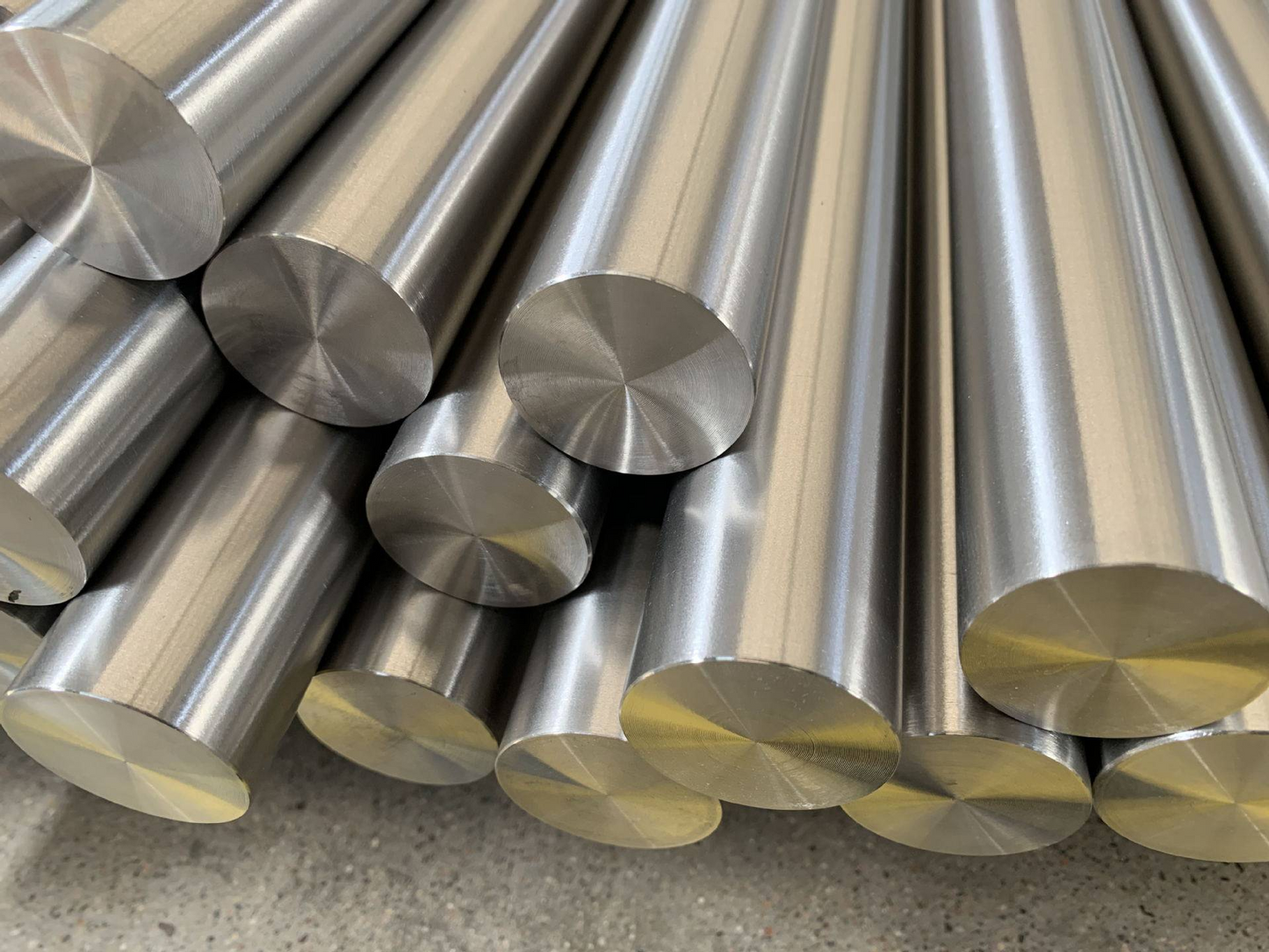

Product Overview

Metallurgische Eigenschaften

Maraging-Stahl verfügt über eine einzigartige, kohlenstoffarme, hochnickelige martensitische Matrix, die während der Lösungsglühbehandlung bei 815-845°C umgewandelt wird. Die Mikrostruktur besteht aus Lamellenmartensit mit feinen, kohärenten Ausscheidungen von Ni3Mo, Ni3Ti und Fe2Mo intermetallischen Verbindungen, die während der Altershärtung gebildet werden. Dieser Ausscheidungshärtungsmechanismus bietet außergewöhnliche Festigkeit bei gleichzeitiger Beibehaltung einer guten Zähigkeit und dimensionalen Stabilität.

Wärmebehandlungsprozess

MetalZenith verwendet einen zweistufigen Wärmebehandlungsprozess: Lösungsglühen bei 820°C, gefolgt von kontrollierter Abkühlung, dann präzise Altershärtung bei 480°C für 3 Stunden. Unsere Vakuumöfen mit Schutzatmosphäre verhindern die Entkohlung und gewährleisten eine gleichmäßige Erwärmung über den Querschnitt, was entscheidend für die Erreichung konsistenter ultra-hochfester Eigenschaften ist.

Exzellenz im Fertigungsprozess

Unser Fertigungsprozess beginnt mit Vakuum-Induktionsschmelzen, um außergewöhnliche Sauberkeit und Homogenität zu gewährleisten. Kontrollierte Schmiede- und Walzvorgänge erhalten die optimale Kornstruktur, gefolgt von präzisen Bearbeitungsmöglichkeiten für komplexe Geometrien. Fortschrittliche Qualitätskontrollen umfassen Ultraschallprüfungen, magnetische Partikelinspektionen und umfassende Verifizierungen der mechanischen Eigenschaften.

Spezialisierte Qualitätsprüfung

MetalZenith führt umfangreiche Tests durch, die spezifisch für strukturelle Anwendungen sind: TIG- und Elektronenstrahlschweißbarkeitseinschätzung mit Optimierung der Nachschweißwärmebehandlung, Formgrenzenanalyse für komplexe Strukturformen, Hochzyklusermüdungstests unter variabler Amplitudenbelastung und Bewertung der atmosphärischen Korrosionsbeständigkeit in industriellen Umgebungen. Diese Tests gewährleisten eine zuverlässige Leistung in kritischen strukturellen Anwendungen.

Ingenieurwesen für strukturelle Anwendungen

Für den Bau von Strukturen bietet unser Maraging-Stahl außergewöhnliche Festigkeits-zu-Gewicht-Verhältnisse, die innovative architektonische Designs ermöglichen. Im Brückenbau gewährleisten die Ermüdungsbeständigkeit und die dimensionale Stabilität des Materials die langfristige strukturelle Integrität unter dynamischer Belastung. Für die Maschinenbauindustrie ermöglicht die Kombination aus hoher Festigkeit und Bearbeitbarkeit präzise Komponenten mit engen Toleranzen. In der Fahrzeugherstellung ermöglicht das Material leichte, aber ultra-starke Sicherheitsstrukturen, während allgemeine Ingenieuranwendungen von der Vielseitigkeit und Zuverlässigkeit des Materials in hochbelasteten Umgebungen profitieren.

🧪 Chemical Composition

| Element | Zusammensetzung (%) |

|---|---|

| Kohlenstoff (C) | ≤ 0.03 |

| Nickel (Ni) | 17.0 - 19.0 |

| Kobalt (Co) | 8.0 - 12.0 |

| Molybdän (Mo) | 4.6 - 5.2 |

| Titan (Ti) | 0.6 - 0.8 |

| Aluminium (Al) | 0.05 - 0.15 |

| Silizium (Si) | ≤ 0.10 |

| Eisen (Fe) | Rest |

⚙️ Mechanical Properties

| Eigenschaft | Wert |

|---|---|

| Streckgrenze (MPa) | ≥ 1720 |

| Zugfestigkeit (MPa) | 1860 - 2070 |

| Dehnung (%) | ≥ 8 |

| Schlagenergie bei RT (J) | ≥ 20 |

| Härte (HRC) | 50 - 55 |

| Wechselfestigkeit (MPa) | ≥ 690 |

🔬 Physical Properties

| Eigenschaft | Wert |

|---|---|

| Dichte (g/cm3) | 8.00 |

| Schmelzpunkt (°C) | 1413 - 1440 |

| Wärmeleitfähigkeit (W/m·K) | 17.4 |

| Wärmeausdehnung (×10??/K) | 10.1 |

| Elastizitätsmodul (GPa) | 186 |

| Poisson-Zahl | 0.31 |

📏 Product Specifications

| Spezifikation | Einzelheiten |

|---|---|

| Verfügbare Formen | Platten, Stangen, Schmiedeteile, Präzisionsbearbeitete Komponenten |

| Dickenbereich | 3 - 200mm |

| Breitenbereich | 100 - 2000mm |

| Längenbereich | 500 - 6000mm |

| Einhaltung von Standards | ASTM A538, AMS 6514, AMS 6521 |

| Wärmebehandlungszustand | Lösungsgeglüht + Alterungshärtung |

| Oberflächenfinish | Warmgewalzt, Kaltbearbeitet, Präzisionsgeschliffen |

Lassen Sie uns Erfolg für Ihr Projekt schaffen

Professionelles Team, Premium-Produkte, Vollständiger Service - Ihr Projekterfolg ist unsere Mission

Our Advantages in Processing Maraging-Stahl

Präzisions-Alterungstechnologie

MetalZenith nutzt fortschrittliches Vakuum-Induktionsschmelzen, gefolgt von präzise gesteuerten Alterungs-Härtungsprozessen bei 480-500°C. Unsere computersteuerbaren Öfen mit einer Temperaturgenauigkeit von ±3°C gewährleisten eine optimale Ausfällung von Ni3Mo, Ni3Ti und Fe2Mo intermetallischen Verbindungen und erreichen konsistente ultra-hochfeste Eigenschaften.

Umfassende strukturelle Tests

Unsere spezialisierten Testprotokolle umfassen fortgeschrittene Schweißbarkeitsbewertungen unter Verwendung kontrollierter thermischer Schweregradtests, Formgrenzenanalysen für komplexe Geometrien, Hochzyklusermüdungstests bis zu 10^7 Zyklen und beschleunigte atmosphärische Korrosionstests. Diese gewährleisten eine optimale Leistung in anspruchsvollen strukturellen Anwendungen.

Maßgeschneiderte Ingenieurlösungen

MetalZenith bietet maßgeschneiderte Alterungshärtungsbehandlungen, präzise Bearbeitungsdienste und umfassende technische Unterstützung für strukturelle Anwendungen. Unsere metallurgischen Ingenieure arbeiten eng mit den Kunden zusammen, um die Materialeigenschaften für spezifische Lastanforderungen und Umweltbedingungen zu optimieren.

IHR VERTRAUENwürdiger STAHL

HERSTELLUNGSPARTNER

Schnellanfrage

Branchen, die wir bedienen

Professionelle Stahl-Lösungen in wichtigen Branchen

Qualifikationen & Zertifizierungen