20 Jahre Erfahrung | 1000+ Markenpartner | Vollständige Anpassung

Wir haben 20 Jahre Branchenerfahrung, haben mit über 1.000 Marken zusammengearbeitet und unterstützen alle Anpassungsbedürfnisse.

Technical Specifications

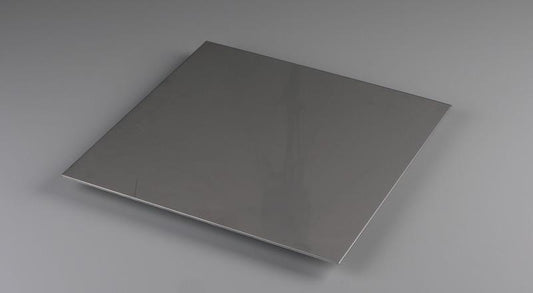

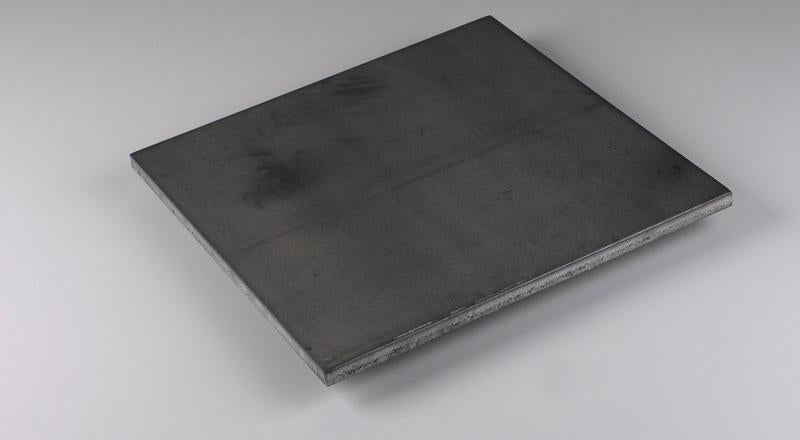

Product Overview

Warmgewalztes Stahlblech wird durch den Warmwalzprozess hergestellt, bei dem Stahl über seine Rekristallisationstemperatur erhitzt und dann gewalzt wird, um die gewünschte Dicke zu erreichen. Dieser Prozess bietet hervorragende mechanische Eigenschaften und eine kosteneffiziente Lösung für strukturelle und allgemeine Ingenieuranwendungen.

Hauptmerkmale:

- Hervorragendes Verhältnis von Festigkeit zu Gewicht

- Gute Schweißbarkeit und Bearbeitbarkeit

- Kosteneffizient für große Struktur-Anwendungen

- Breite Palette an Dicke und Größenverfügbarkeit

- Geeignet für verschiedene Fertigungsprozesse

Herstellungsprozess: Warmgewalzt unter Verwendung von kontrollierter Walztechnologie mit präziser Temperaturkontrolle, die konsistente mechanische Eigenschaften und Maßgenauigkeit über das gesamte Blech gewährleistet.

Anwendungen: Strukturale Konstruktion, Schiffbau, Druckbehälter, allgemeine Fertigung, Maschinenkomponenten, Brücken, Gebäude und Herstellung von schweren Geräten.

🧪 Chemical Composition

| Element | Min % | Max % | Typisch % | ASTM A36 Anforderung |

|---|---|---|---|---|

| Kohlenstoff (C) | - | 0.26 | 0.18 | ≤ 0.26 |

| Mangan (Mn) | 0.80 | 1.20 | 0.95 | 0.80-1.20 |

| Silizium (Si) | 0.15 | 0.40 | 0.25 | 0.15-0.40 |

| Phosphor (P) | - | 0.040 | 0.025 | ≤ 0.040 |

| Schwefel (S) | - | 0.050 | 0.030 | ≤ 0.050 |

| Kupfer (Cu) | - | 0.20 | 0.12 | ≤ 0.20 |

| Nickel (Ni) | - | 0.20 | 0.08 | ≤ 0.20 |

| Chrom (Cr) | - | 0.20 | 0.10 | ≤ 0.20 |

| Eisen (Fe) | Rest | Rest | 98.2 | Rest |

⚙️ Mechanical Properties

| Eigenschaft | ASTM-Anforderung | Typischer Wert | Prüfmethode | Temperatur |

|---|---|---|---|---|

| Zugfestigkeit | 400-550 MPa | 485 MPa | ASTM A370 | Raumtemperatur |

| Streckgrenze | 250 MPa min | 275 MPa | ASTM A370 | Raumtemperatur |

| Dehnung | 20% min | 26% | ASTM A370 | Raumtemperatur |

| Härte (Brinell) | - | 140-180 HB | ASTM E10 | Raumtemperatur |

| Härte (Rockwell B) | - | 75-85 HRB | ASTM E18 | Raumtemperatur |

| Elastizitätsmodul | - | 200 GPa | ASTM E111 | Raumtemperatur |

| Schlagenergie (Charpy V) | - | 80-120 J | ASTM E23 | Raumtemperatur |

🔬 Physical Properties

| Eigenschaft | Wert | Einheit | Temperatur | Prüfstandard |

|---|---|---|---|---|

| Dichte | 7.85 | g/cm3 | 20°C | ASTM B311 |

| Schmelzpunkt | 1510-1540 | °C | - | DSC-Analyse |

| Wärmeleitfähigkeit | 50-60 | W/m·K | 100°C | ASTM E1461 |

| Spezifische Wärme | 460 | J/kg·K | 0-100°C | ASTM C351 |

| Lineare Ausdehnung | 11.7 | μm/m·K | 0-100°C | ASTM E228 |

| Elektrische Widerstandsfähigkeit | 170-200 | n|°¤m | 20°C | ASTM B193 |

| Magnetische Permeabilität | Hoch | μ/μ₀ | Raumtemperatur | ASTM A342 |

| Curie-Temperatur | 770 | °C | - | Ferromagnetisch |

📏 Product Specifications

| Spezifikation | Verfügbarer Bereich | Standardgröße | Benutzerdefiniert verfügbar | Toleranz |

|---|---|---|---|---|

| Dicke | 3mm - 200mm | 6-50mm | Ja | ±0.3mm |

| Breite | 1000mm - 3500mm | 1500-2000mm | Ja | ±5mm |

| Länge | 2000mm - 12000mm | 6000mm | Ja | +50mm/-0mm |

| Oberflächenfinish | Walzhaut, Entzundert, Strahlbehandlung | Walzhaut | Ja | Ra ≤ 12.5μm |

| Kantenzustand | Walzkante, Geschnitten, Brennschneiden | Walzkante | Ja | ASTM-Standard |

| Planheit | Klasse A, B, C | Klasse B | Ja | ASTM A6 |

| Normenkonformität | ASTM A36, A572, A514 | A36 | Mehrere | Vollständige Konformität |

| Wärmebehandlung | Wie gewalzt, Normalisiert | Wie gewalzt | Ja | ASTM A6 |

| Prüfzertifikat | Walz TC, EN 10204 3.1 | Walz TC | Ja | Standard |

| Verpackung | Bündel, Kisten, Lose | Bündel | Benutzerdefiniert | Exportstandard |

Lassen Sie uns Erfolg für Ihr Projekt schaffen

Professionelles Team, Premium-Produkte, Vollständiger Service - Ihr Projekterfolg ist unsere Mission

Our Advantages in Processing Warmgewalztes Stahlblech

Hochtemperaturverarbeitung

Das Walzen von Stahl bei Temperaturen über 1700°F ermöglicht eine optimale Verformbarkeit und Formbarkeit, wodurch eine effiziente Formgebung großer Platten bei gleichbleibenden Materialeigenschaften im gesamten Stück gewährleistet wird. Dieser Hochtemperaturprozess reduziert die für die Verformung erforderliche Energie.

Effiziente Ein-Pass-Formation

Das Warmwalzen ermöglicht eine erhebliche Größenreduzierung in einem einzigen Durchgang, wodurch es möglich ist, große Stahlabschnitte schnell und effizient zu bearbeiten. Dies führt zu höheren Produktionsraten und niedrigeren Herstellungskosten im Vergleich zu Kaltwalzprozessen.

Verbesserte Materialstärke

Der Warmwalzprozess verfeinert die Kornstruktur des Stahls während der Rekristallisation, was zu verbesserten mechanischen Eigenschaften und einer gleichmäßigen Festigkeitsverteilung über die Platte führt. Dies resultiert in einer besseren strukturellen Integrität für Anwendungen im Schwerlastbereich.

IHR VERTRAUENwürdiger STAHL

HERSTELLUNGSPARTNER

Schnellanfrage

Branchen, die wir bedienen

Professionelle Stahl-Lösungen in wichtigen Branchen

Qualifikationen & Zertifizierungen