20 Jahre Erfahrung | 1000+ Markenpartner | Vollständige Anpassung

Wir haben 20 Jahre Branchenerfahrung, haben mit über 1.000 Marken zusammengearbeitet und unterstützen alle Anpassungsbedürfnisse.

Technical Specifications

Product Overview

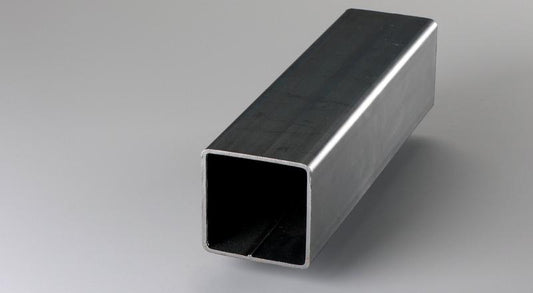

Elektrisch geschweißtes (ERW) Rundstahlrohr wird mit Hilfe von Hochfrequenz-Elektrowiderstandsschweißtechnologie aus hochwertigem Kohlenstahlband hergestellt. Dieser Prozess erzeugt eine starke, kontinuierliche Schweißnaht, die eine hervorragende strukturelle Integrität und eine gleichmäßige Wandstärke über die gesamte Rohrlänge bietet.

Hauptmerkmale:

- Überlegene Maßgenauigkeit und Konsistenz

- Glatte Innen- und Außenoberflächenbeschaffenheit

- Ausgezeichnete Schweißbarkeit und Bearbeitbarkeit

- Kosteneffizienter Herstellungsprozess

- Breite Palette von Größen und Wandstärken verfügbar

Herstellungsprozess: Hochfrequenz-Elektrowiderstandsschweißprozess (ERW), bei dem das Stahlband in Rohrform gebracht und unter Verwendung von elektrischer Widerstandserwärmung geschweißt wird, gefolgt von Größen- und Fertigungsoperationen.

Anwendungen: Strukturale Anwendungen, Maschinenbau, Automobilkomponenten, Möbelherstellung, Bauprojekte, Fluidtransport Systeme und allgemeine Fertigungsarbeiten, die runde Hohlprofile erfordern.

🧪 Chemical Composition

| Element | Min % | Max % | Typisch % | ASTM A513 Anforderung |

|---|---|---|---|---|

| Kohlenstoff (C) | 0.15 | 0.25 | 0.20 | 0.15-0.25 |

| Mangan (Mn) | 0.30 | 0.60 | 0.45 | 0.30-0.60 |

| Phosphor (P) | - | 0.040 | 0.025 | ≤ 0.040 |

| Schwefel (S) | - | 0.050 | 0.030 | ≤ 0.050 |

| Silizium (Si) | 0.15 | 0.35 | 0.25 | 0.15-0.35 |

| Kupfer (Cu) | - | 0.20 | 0.10 | ≤ 0.20 |

| Nickel (Ni) | - | 0.20 | 0.10 | ≤ 0.20 |

| Chrom (Cr) | - | 0.15 | 0.08 | ≤ 0.15 |

| Eisen (Fe) | Rest | Rest | 98.9 | Rest |

⚙️ Mechanical Properties

| Eigenschaft | ASTM-Anforderung | Typischer Wert | Prüfmethode | Temperatur |

|---|---|---|---|---|

| Zugfestigkeit | 400 MPa min | 450 MPa | ASTM A370 | Raumtemperatur |

| Streckgrenze (0,2%) | 220 MPa min | 250 MPa | ASTM A370 | Raumtemperatur |

| Dehnung | 20% min | 25% | ASTM A370 | Raumtemperatur |

| Härte (Brinell) | - | 130 HB | ASTM E10 | Raumtemperatur |

| Härte (Rockwell B) | - | 75 HRB | ASTM E18 | Raumtemperatur |

| Elastizitätsmodul | - | 210 GPa | ASTM E111 | Raumtemperatur |

| Schlagenergie (Charpy V) | - | 80+ J | ASTM E23 | Raumtemperatur |

🔬 Physical Properties

| Eigenschaft | Wert | Einheit | Temperatur | Prüfstandard |

|---|---|---|---|---|

| Dichte | 7.85 | g/cm3 | 20°C | ASTM B311 |

| Schmelzpunkt | 1510-1540 | °C | - | DSC-Analyse |

| Wärmeleitfähigkeit | 50.2 | W/m·K | 100°C | ASTM E1461 |

| Spezifische Wärme | 460 | J/kg·K | 0-100°C | ASTM C351 |

| Lineare Ausdehnung | 11.5 | μm/m·K | 0-100°C | ASTM E228 |

| Elektrische Widerstandsfähigkeit | 170 | n|°¤m | 20°C | ASTM B193 |

| Magnetische Permeabilität | Hoch | μ/μ₀ | Raumtemperatur | ASTM A342 |

| Curie-Temperatur | 770 | °C | - | Ferromagnetisch |

📏 Product Specifications

| Spezifikation | Verfügbarer Bereich | Standardlänge | Benutzerdefiniert verfügbar | Toleranz |

|---|---|---|---|---|

| Außendurchmesser (OD) | 10mm - 508mm | Verschiedene | Ja | ±0.5mm |

| Wandstärke | 1.0mm - 20mm | Verschiedene | Ja | ±10% |

| Länge | 1m - 12m | 6m | Ja | +50mm/-0mm |

| Oberflächenfinish | Schwarz, Verzinkt, Lackiert | Schwarz | Ja | Ra ≤ 6.3μm |

| Schweißtyp | ERW (Elektrischer Widerstand) | ERW | Standard | ASTM-Standard |

| Endverbindung | Glatt, Abgewinkelt, Gewindet | Glatt | Ja | ASME B36.10 |

| Normen-Konformität | ASTM A513, A500, A501 | A513 | Mehrere | Vollständige Konformität |

| Gradoptionen | Grad A, Grad B, Grad C | Grad B | Ja | Gemäß Spezifikation |

| Prüfzertifikat | Mill TC, EN 10204 3.1 | Mill TC | Ja | Standard |

| Verpackung | Bündel, Kisten, Container | Bündel | Benutzerdefiniert | Exportstandard |

Lassen Sie uns Erfolg für Ihr Projekt schaffen

Professionelles Team, Premium-Produkte, Vollständiger Service - Ihr Projekterfolg ist unsere Mission

Our Advantages in Processing Elektrisch geschweißtes (ERW) rundes Stahlrohr

Präzise elektrische Schweißkontrolle

Die fortschrittliche elektrische Widerstandsschweißtechnologie gewährleistet eine konsistente Nahtqualität und überlegene Verbindungsfestigkeit. Computersteuerbare Schweißparameter halten während des Schweißprozesses eine präzise Temperatur und einen präzisen Druck aufrecht, was zu einer zuverlässigen, hochintegren Rohrbildung führt.

Einheitliche Wandstärke

Der ERW-Herstellungsprozess ermöglicht eine außergewöhnliche Kontrolle über die Konsistenz der Wandstärke durch automatisiertes Walzen und Formen. Diese Präzision führt zu Rohren mit minimalen Dickenvariationen, die eine optimale strukturelle Integrität und Leistung gewährleisten.

Effiziente kontinuierliche Produktion

Die elektrisch geschweißte Rohrproduktionslinie arbeitet kontinuierlich und ermöglicht eine hochvolumige Fertigung mit minimalen Ausfallzeiten. Dieser optimierte Prozess senkt die Produktionskosten und gewährleistet gleichzeitig eine gleichbleibende Qualität über lange Produktionsläufe hinweg.

IHR VERTRAUENwürdiger STAHL

HERSTELLUNGSPARTNER

Schnellanfrage

Branchen, die wir bedienen

Professionelle Stahl-Lösungen in wichtigen Branchen

Qualifikationen & Zertifizierungen