20 Jahre Erfahrung | 1000+ Markenpartner | Vollständige Anpassung

Wir haben 20 Jahre Branchenerfahrung, haben mit über 1.000 Marken zusammengearbeitet und unterstützen alle Anpassungsbedürfnisse.

Technical Specifications

Product Overview

Metallurgische Eigenschaften

ETD 150 weist eine feinkörnige, vergütete martensitische Mikrostruktur auf, die durch kontrolliertes Abschrecken und Anlassen erreicht wird. Die optimierte Legierungszusammensetzung mit Zusätzen von Chrom, Nickel und Molybdän bietet eine verbesserte Härtbarkeit und verbesserte mechanische Eigenschaften. Die verfeinerte Kornstruktur gewährleistet ein ausgezeichnetes Verhältnis von Festigkeit zu Zähigkeit, das für strukturelle Anwendungen unerlässlich ist.

Wärmebehandlungsprozess

MetalZenith verwendet kontrolliertes Austenitisieren bei 850-900°C, gefolgt von Wasserabschrecken und Anlassen bei 580-620°C. Dieser präzise Wärmebehandlungszyklus gewährleistet optimale mechanische Eigenschaften und erhält gleichzeitig hervorragende Schweißbarkeit und Formbarkeit, die für die strukturelle Fertigung erforderlich sind.

Fertigungsprozess

Unsere ETD 150-Produktion nutzt das Schmelzen im Lichtbogenofen mit sekundärer Raffination, kontinuierlichem Gießen und kontrollierten Walzprozessen. Die fortschrittliche Qualitätskontrolle umfasst die Echtzeit-Temperaturüberwachung, Ultraschallprüfung und umfassende Verifizierung der mechanischen Eigenschaften, um eine konsistente strukturelle Leistung sicherzustellen.

Strukturelle Qualitätsprüfung

MetalZenith führt umfangreiche Tests durch, die spezifisch für strukturelle Anwendungen sind, einschließlich der Bewertung der Schweißbarkeit gemäß AWS D1.1, der Bewertung der Formleistung, der Ermüdungsfestigkeitsprüfung unter zyklischer Belastung und der Prüfung der atmosphärischen Korrosionsbeständigkeit. Diese spezialisierten Tests gewährleisten optimale Leistung in Bau- und Ingenieurumgebungen.

Anwendungsengineering

Für den Bau bietet ETD 150 ein ausgezeichnetes Verhältnis von Festigkeit zu Gewicht, das leichtere strukturelle Designs ermöglicht. Im Brückenbau gewährleistet die überlegene Ermüdungsbeständigkeit eine langfristige Haltbarkeit unter dynamischer Belastung. Für die Maschinenbauindustrie erleichtern hervorragende Bearbeitbarkeit und Schweißbarkeit die komplexe Fertigung. Im Fahrzeugbau ermöglicht die hohe Festigkeit eine Gewichtsreduzierung bei gleichzeitiger Einhaltung der Sicherheitsstandards. Allgemeine Ingenieuranwendungen profitieren von vielseitigen Formfähigkeiten und zuverlässigen mechanischen Eigenschaften.

🧪 Chemical Composition

| Element | Zusammensetzung (%) |

|---|---|

| Kohlenstoff (C) | 0.15 - 0.23 |

| Mangan (Mn) | 1.20 - 1.65 |

| Silizium (Si) | 0.15 - 0.40 |

| Phosphor (P) | ≤ 0.030 |

| Schwefel (S) | ≤ 0.030 |

| Chrom (Cr) | 0.30 - 0.65 |

| Nickel (Ni) | 0.25 - 0.50 |

| Molybdän (Mo) | 0.15 - 0.25 |

⚙️ Mechanical Properties

| Eigenschaft | Wert |

|---|---|

| Streckgrenze (MPa) | ≥ 550 |

| Zugfestigkeit (MPa) | 650 - 850 |

| Dehnung (%) | ≥ 18 |

| Schlagenergie bei 0°C (J) | ≥ 35 |

| Härte (HB) | 180 - 250 |

| Wechselfestigkeit (MPa) | 280 - 320 |

🔬 Physical Properties

| Eigenschaft | Wert |

|---|---|

| Dichte (g/cm3) | 7.85 |

| Schmelzpunkt (°C) | 1480 - 1520 |

| Wärmeleitfähigkeit (W/m·K) | 42.5 |

| Wärmeausdehnung (×10??/K) | 11.8 |

| Elastizitätsmodul (GPa) | 210 |

| Poisson-Zahl | 0.27 - 0.30 |

📏 Product Specifications

| Spezifikation | Einzelheiten |

|---|---|

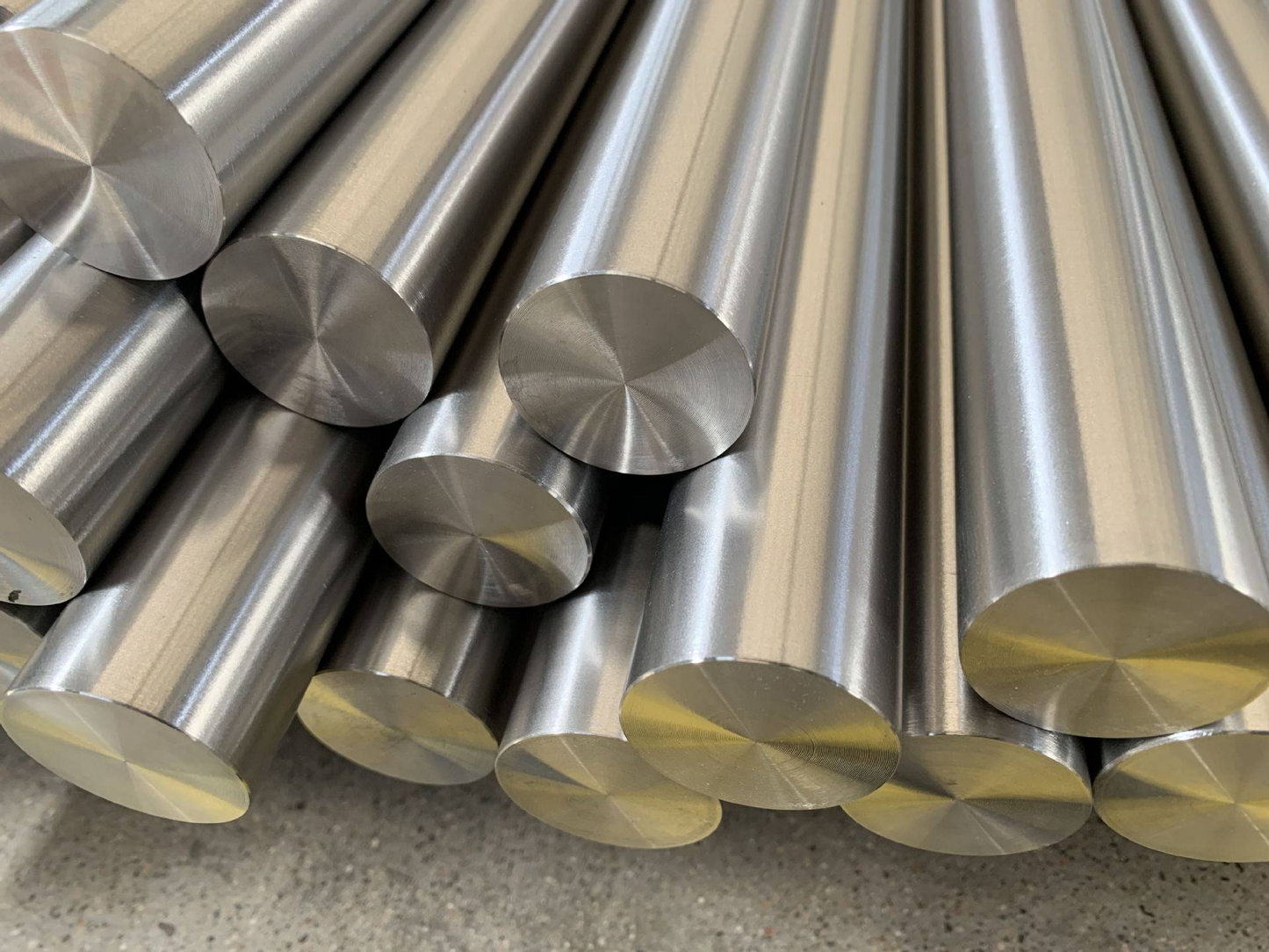

| Verfügbare Formen | Platten, Träger, Kanäle, Winkel, Stangen, Rohre |

| Dickenbereich | 8 - 150mm |

| Breitenbereich | 1200 - 3500mm |

| Längenbereich | 6000 - 15000mm |

| Einhaltung von Standards | ASTM A572, EN 10025-6, JIS G3106 |

| Wärmebehandlungszustand | Abgeschreckt und Anlassen (Q&T) |

| Oberflächenfinish | Warmgewalzt, Entzundert, Strahlgebläßt |

Lassen Sie uns Erfolg für Ihr Projekt schaffen

Professionelles Team, Premium-Produkte, Vollständiger Service - Ihr Projekterfolg ist unsere Mission

Our Advantages in Processing ETD 150 Stahl

Fortgeschrittene thermomechanische Verarbeitung

MetalZenith nutzt kontrolliertes Walzen mit präziser Temperaturkontrolle, gefolgt von beschleunigter Abkühlung, um eine optimale Mikrostruktur im ETD 150-Stahl zu erreichen. Unsere fortschrittliche Verarbeitungstechnologie gewährleistet eine gleichmäßige Kornverfeinerung und verbesserte mechanische Eigenschaften, die überlegene Festigkeit und Zähigkeit für strukturelle Anwendungen bieten.

Umfassende strukturelle Tests

Unser ETD 150 Stahl unterliegt umfangreichen Tests, einschließlich der Bewertung der Schweißbarkeit, der Bewertung der Formbarkeit, der Prüfung der Ermüdungsfestigkeit und der Analyse der atmosphärischen Korrosionsbeständigkeit. Das Qualitätsmanagementprogramm von MetalZenith gewährleistet eine optimale Leistung in strukturellen Anwendungen mit nachgewiesener langfristiger Haltbarkeit.

Maßgeschneiderte Struktur Lösungen

MetalZenith bietet umfassende Anpassungsdienste für Stahl ETD 150 an, einschließlich präziser Zuschnitte, Formgebung, Optimierung der Wärmebehandlung und Oberflächenvorbereitung. Unser technisches Support-Team arbeitet eng mit Bauingenieuren zusammen, um maßgeschneiderte Lösungen für spezifische Bau- und Ingenieuranforderungen zu liefern.

IHR VERTRAUENwürdiger STAHL

HERSTELLUNGSPARTNER

Schnellanfrage

Branchen, die wir bedienen

Professionelle Stahl-Lösungen in wichtigen Branchen

Qualifikationen & Zertifizierungen