20 Jahre Erfahrung | 1000+ Markenpartner | Vollständige Anpassung

Wir haben 20 Jahre Branchenerfahrung, haben mit über 1.000 Marken zusammengearbeitet und unterstützen alle Anpassungsbedürfnisse.

Technical Specifications

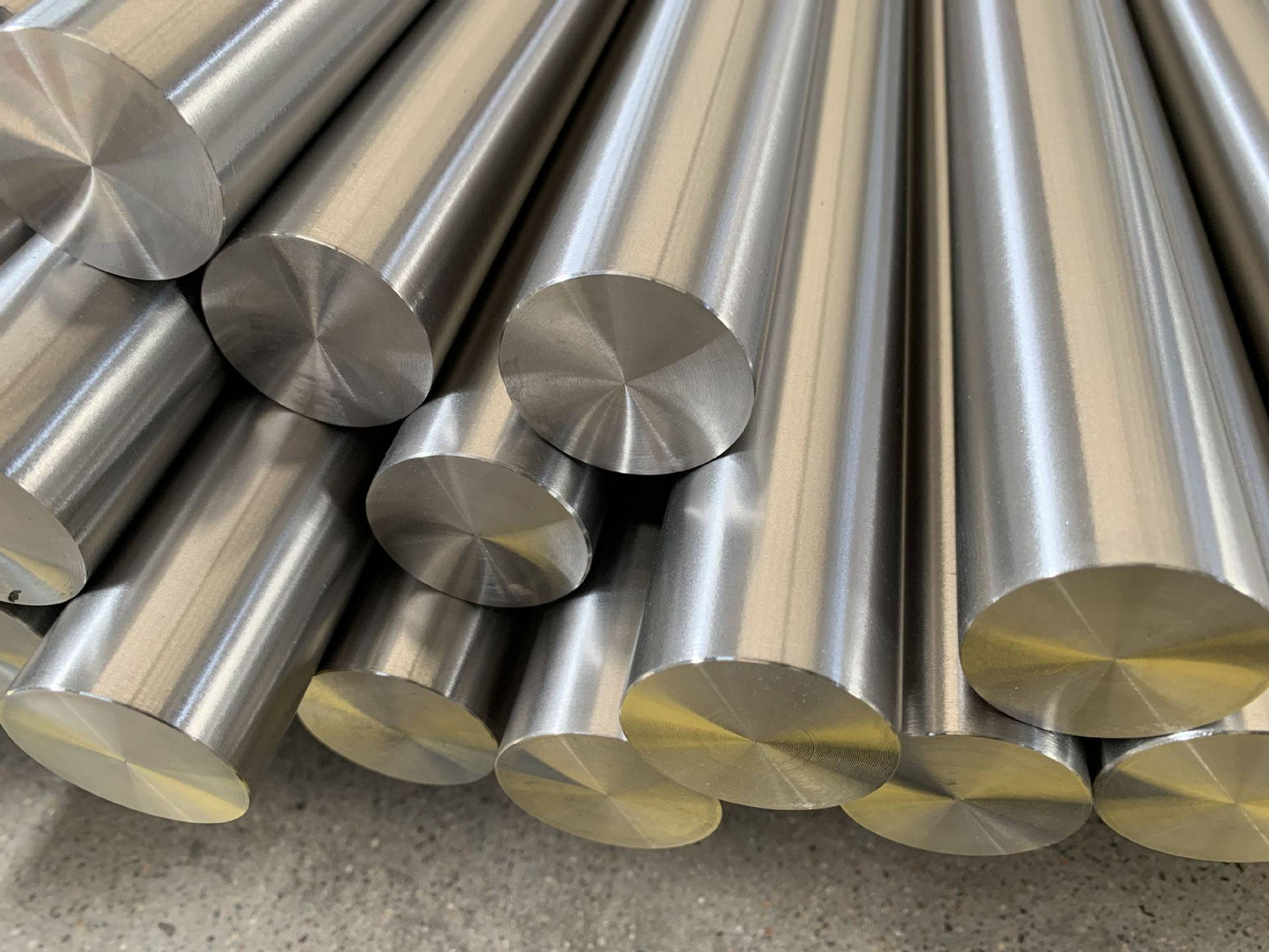

Product Overview

Metallurgische Eigenschaften

EN45 ist ein mittelkohlenstoffhaltiger Baustahl mit einer überwiegend perlitischen Mikrostruktur im normalisierten Zustand. Der kontrollierte Kohlenstoffgehalt bietet hervorragende Festigkeit und Härte, während eine angemessene Duktilität für strukturelle Anwendungen erhalten bleibt. Die feinkörnige Mikrostruktur, die durch kontrolliertes Walzen erreicht wird, verbessert sowohl die Festigkeits- als auch die Zähigkeitseigenschaften.

Wärmebehandlungsprozess

MetalZenith verwendet kontrolliertes Normalisieren bei 850-900°C, gefolgt von Luftkühlung für eine optimale mikrostrukturelle Entwicklung. Für verbesserte Eigenschaften sorgt das Abschrecken von 820-860°C, gefolgt von Anlassen bei 550-650°C für ein überlegenes Festigkeits-Zähigkeits-Verhältnis. Unsere präzise Temperaturkontrolle gewährleistet konsistente mechanische Eigenschaften im gesamten Materialquerschnitt.

Herstellungsprozess

Unser fortschrittlicher Herstellungsprozess umfasst das Schmelzen im Lichtbogenofen, die Pfannenverfeinerung zur genauen Chemiekontrolle und das kontinuierliche Gießen zur Verbesserung der Homogenität. Kontrolliertes Walzen mit optimierten Reduktionsplänen sorgt für eine feinkörnige Struktur und verbesserte mechanische Eigenschaften. Die Wärmebehandlung nach dem Walzen wird sorgfältig kontrolliert, um die Zielwerte zu erreichen.

Prüfung der strukturellen Qualität

EN45 unterliegt umfassenden Tests, einschließlich der Bewertung der Schweißleistung nach Standardverfahren, der Beurteilung der Formfähigkeit durch Biegetests, der Ermüdungsfestigkeitsprüfung unter zyklischer Belastung und der Bewertung der atmosphärischen Korrosionsbeständigkeit. Diese spezialisierten Tests gewährleisten eine optimale Leistung in strukturellen Anwendungen, bei denen Zuverlässigkeit entscheidend ist.

Ingenieurtechnische Überlegungen zur Anwendung

Für den Bau von Gebäuden bietet EN45 eine hervorragende Tragfähigkeit und Erdbebenresistenz. Im Brückenbau gewährleisten seine Ermüdungsbeständigkeit und Witterungseigenschaften eine langfristige Haltbarkeit. Für die Maschinenherstellung ermöglicht die Kombination aus Festigkeit und Bearbeitbarkeit die Herstellung komplexer Komponenten. Im Fahrzeugbau optimiert das Verhältnis von Festigkeit zu Gewicht die strukturelle Effizienz und erfüllt gleichzeitig die Sicherheitsstandards.

🧪 Chemical Composition

| Element | Zusammensetzung (%) |

|---|---|

| Kohlenstoff (C) | 0.42 - 0.50 |

| Mangan (Mn) | 0.50 - 0.80 |

| Silizium (Si) | 0.10 - 0.40 |

| Phosphor (P) | ≤ 0.035 |

| Schwefel (S) | ≤ 0.035 |

| Chrom (Cr) | 0.15 - 0.35 |

| Nickel (Ni) | ≤ 0.30 |

| Molybdän (Mo) | ≤ 0.10 |

⚙️ Mechanical Properties

| Eigenschaft | Wert |

|---|---|

| Streckgrenze (MPa) | ≥ 355 |

| Zugfestigkeit (MPa) | 630 - 780 |

| Dehnung (%) | ≥ 16 |

| Schlagenergie bei 20°C (J) | ≥ 35 |

| Härte (HB) | 180 - 230 |

| Ermüdungsfestigkeit (MPa) | 280 - 320 |

🔬 Physical Properties

| Eigenschaft | Wert |

|---|---|

| Dichte (g/cm3) | 7.85 |

| Schmelzpunkt (°C) | 1460 - 1520 |

| Wärmeleitfähigkeit (W/m·K) | 42.6 |

| Wärmeausdehnung (×10??/K) | 11.5 |

| Elastizitätsmodul (GPa) | 210 |

| Poisson-Zahl | 0.27 - 0.30 |

📏 Product Specifications

| Spezifikation | Einzelheiten |

|---|---|

| Verfügbare Formen | Platten, Bleche, Stangen, Träger, Profile, Winkel |

| Dickenbereich | 3 - 150mm |

| Breitenbereich | 500 - 3000mm |

| Längenbereich | 3000 - 12000mm |

| Einhaltung von Standards | EN 10083-2, ASTM A29, JIS G4051 |

| Wärmebehandlungszustand | Normalisiert, Vergütet & Temperiert |

| Oberflächenfinish | Warmgewalzt, Kaltgezogen, Bearbeitet |

Lassen Sie uns Erfolg für Ihr Projekt schaffen

Professionelles Team, Premium-Produkte, Vollständiger Service - Ihr Projekterfolg ist unsere Mission

Our Advantages in Processing EN45 Stahl

Fortgeschrittene Wärmebehandlungsverarbeitung

MetalZenith verwendet kontrollierte Abschreck- und Anlasprozesse mit präziser Temperaturüberwachung, um optimale Härte- und Festigkeitsverteilung zu erreichen. Unsere fortschrittliche Wärmebehandlung gewährleistet konsistente mechanische Eigenschaften über den gesamten Querschnitt des Materials und maximiert die strukturelle Leistung.

Umfassende strukturelle Tests

Unser EN45-Stahl unterliegt strengen Tests, einschließlich der Bewertung der Schweißleistung, der Beurteilung der Formfähigkeit, der Ermüdungsfestigkeitsprüfung und der Analyse der atmosphärischen Korrosionsbeständigkeit. Diese umfassenden Tests gewährleisten eine optimale Leistung in strukturellen Anwendungen.

Maßgeschneiderte Fertigungsdienstleistungen

MetalZenith bietet umfassende maßgeschneiderte Bearbeitungsdienste, einschließlich Schneiden, Bearbeiten, Wärmebehandlung und Oberflächenveredelung. Unser technisches Team bietet fachkundige Beratung zur Optimierung des strukturellen Designs und zur Auswahl von Materialien.

IHR VERTRAUENwürdiger STAHL

HERSTELLUNGSPARTNER

Schnellanfrage

Branchen, die wir bedienen

Professionelle Stahl-Lösungen in wichtigen Branchen

Qualifikationen & Zertifizierungen