20 лет опыта | 1000+ партнеров по брендам | Полная настройка

У нас 20 лет опыта в отрасли, мы сотрудничаем с более чем 1,000 брендами и поддерживаем любые потребности в настройке.

Technical Specifications

Product Overview

Металлургические характеристики

S450 - это высокопрочная низколегированная (HSLA) конструкционная сталь с утонченной ферритно-бейнитной микроструктурой. Контролируемое добавление микроалюминиевых элементов, включая ниобий и ванадий, способствует упрочнению зерна и осаждению, что приводит к оптимальному сочетанию прочности, ударной вязкости и свариваемости, необходимых для конструкционных приложений.

Процесс термообработки

MetalZenith использует термомеханическую контролируемую переработку (TMCP) с контролируемыми температурами прокатки от 850 до 950°C, за которыми следует ускоренное охлаждение. Альтернативная термообработка включает закалку при 900-950°C с последующим отпуском при 580-650°C для достижения оптимального баланса прочности и ударной вязкости для конструкционных приложений.

Совершенство производственного процесса

Современный производственный процесс MetalZenith включает непрерывную литье, контролируемую прокатку с точным мониторингом температуры и оптимизированные стратегии охлаждения. Наши современные предприятия обеспечивают постоянный химический состав и механические свойства по всему сечению материала, что критически важно для структурной целостности.

Специализированное качество тестирования

Комплексные протоколы тестирования включают оценку производительности сварки с использованием стандартизированных процедур, оценку формуемости через испытания на изгиб, определение прочности на усталость при циклических нагрузках и испытания на атмосферную коррозию в смоделированных экологических условиях. Эти специализированные тесты обеспечивают соответствие стали S450 строгим требованиям конструкционных приложений.

Технические соображения, специфичные для применения

Для строительства зданий S450 обеспечивает отличное соотношение прочности и веса, позволяя создавать более легкие конструктивные решения. В мостостроении превосходная усталостная стойкость обеспечивает долговечность при динамических нагрузках. Для производства машин исключительная свариваемость облегчает сложные процессы изготовления. В строительстве транспортных средств высокая прочность позволяет снизить вес при соблюдении стандартов безопасности. Для общих инженерных приложений постоянные механические свойства обеспечивают надежную работу в различных условиях эксплуатации.

🧪 Chemical Composition

| Элемент | Состав (%) |

|---|---|

| Углерод (C) | ≤ 0.20 |

| Марганец (Mn) | 1.20 - 1.70 |

| Кремний (Si) | 0.15 - 0.60 |

| Фосфор (P) | ≤ 0.030 |

| Сера (S) | ≤ 0.025 |

| Алюминий (Al) | ≥ 0.015 |

| Ниобий (Nb) | 0.015 - 0.060 |

| Ванадий (V) | 0.02 - 0.12 |

⚙️ Mechanical Properties

| Свойство | Значение |

|---|---|

| Предельная прочность (МПа) | ≥ 450 |

| Тянущая прочность (МПа) | 550 - 720 |

| Удлинение (%) | ≥ 17 |

| Энергия удара при -20°C (Дж) | ≥ 27 |

| Твердость (HB) | 160 - 220 |

| Выносливость (МПа) | ≥ 225 |

🔬 Physical Properties

| Свойство | Значение |

|---|---|

| Плотность (г/см3) | 7.85 |

| Температура плавления (°C) | 1510 - 1540 |

| Теплопроводность (Вт/м·К) | 50.2 |

| Тепловое расширение (×10??/К) | 11.8 |

| Модуль упругости (ГПа) | 210 |

| Коэффициент Пуассона | 0.30 |

📏 Product Specifications

| Спецификация | Детали |

|---|---|

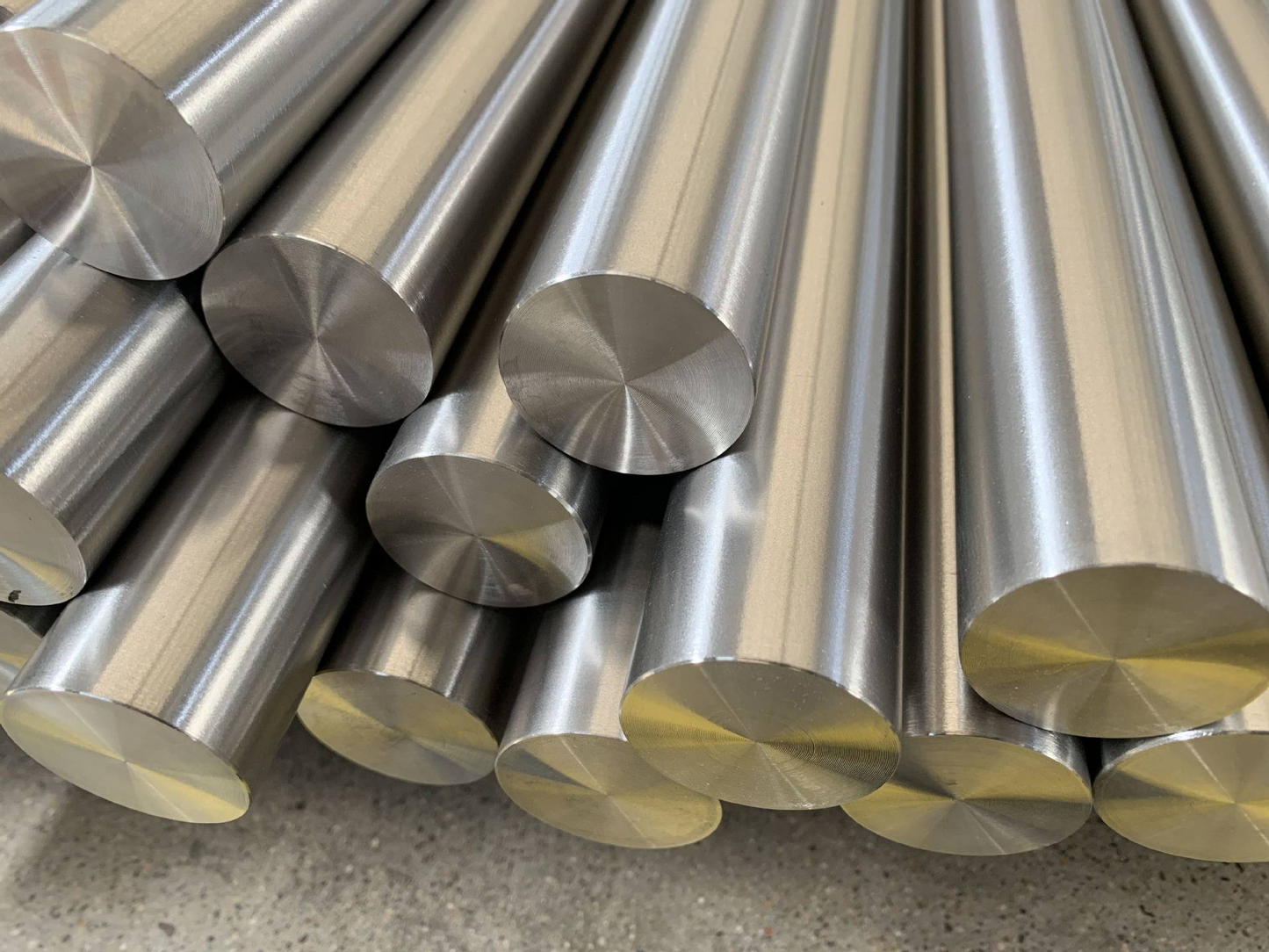

| Доступные формы | Плиты, Балки, Каналы, Углы, Штанги, Трубы |

| Диапазон толщины | 3 - 80мм |

| Диапазон ширины | 1000 - 3200мм |

| Диапазон длины | 6000 - 15000мм |

| Соответствие стандартам | EN 10025-4, ASTM A572 Grade 65, JIS G3106 |

| Условия термообработки | TMCP, Закаленный и отпущенный, Нормализованный |

| Поверхностная отделка | Горячекатаный, Стреляный, Кислотный и масляный |

Давайте создадим успех для вашего проекта

Профессиональная команда, премиум-продукты, полный сервис - успех вашего проекта является нашей миссией

Our Advantages in Processing S450 Сталь

Продвинутая термомеханическая обработка

MetalZenith использует современную технологию TMCP с контролируемой прокаткой и точными скоростями охлаждения для достижения оптимальной микроструктуры и улучшенных механических свойств. Наши передовые процессы обеспечивают постоянную прочность и вязкость по всему сечению материала, обеспечивая превосходные структурные характеристики.

Комплексное структурное тестирование

MetalZenith проводит обширные испытательные протоколы, включая оценку производительности сварки, оценку формовочных возможностей, испытания на усталостную прочность и анализ устойчивости к атмосферной коррозии. Наша строгая система обеспечения качества гарантирует, что сталь S450 соответствует строгим требованиям конструктивных приложений.

Пользовательские инженерные решения

MetalZenith предоставляет комплексные услуги по индивидуальной обработке, включая точное резание, формование, подготовку сварки и оптимизацию термической обработки. Наша команда технической поддержки тесно сотрудничает со строительными инженерами, чтобы предоставить индивидуальные решения для конкретных строительных и инженерных требований.

ВАШ НАДЕЖНЫЙ СТАЛЬ

ПАРТНЕР ПО ПРОИЗВОДСТВУ

Быстрый запрос

Отрасли, которые мы обслуживаем

Профессиональные стальные решения для основных отраслей

Квалификации и сертификаты