20 лет опыта | 1000+ партнеров по брендам | Полная настройка

У нас 20 лет опыта в отрасли, мы сотрудничаем с более чем 1,000 брендами и поддерживаем любые потребности в настройке.

Technical Specifications

Product Overview

Металлургические характеристики

R260 - это мелкозернистая конструкционная сталь с преимущественно ферритно-перлитной микроструктурой, оптимизированной для конструкционных приложений. Контролируемое добавление микроалюминирующих элементов, таких как ниобий и титан, способствует упрочнению зерна и осаждению, что приводит к отличному соотношению прочности и веса и превосходной формуемости, необходимой для сложного конструкционного производства.

Процесс термообработки

MetalZenith использует контролируемую прокатку, за которой следует ускоренное охлаждение или нормализация при 880-920°C с контролируемыми скоростями охлаждения для достижения оптимальных механических свойств. Наше термомеханическое обработка обеспечивает однородную микроструктуру и повышенную прочность при сохранении отличной свариваемости для конструкционных приложений.

Отличие в производстве

Наш продвинутый производственный процесс включает мониторинг температуры в реальном времени и контролируемые графики деформации для оптимизации структуры зерна. Современные прокатные станы и установки термообработки MetalZenith обеспечивают постоянные механические свойства и точность размеров, критически важные для приложений конструкционной стали.

Специализированное качество тестирования

R260 проходит комплексное тестирование, включая оценку сварочной производительности с использованием стандартных процедур, оценку формуемости через испытания на изгиб, испытания на усталостную прочность при циклической нагрузке и оценку устойчивости к атмосферной коррозии. Эти специализированные тесты обеспечивают оптимальную производительность в сложных конструкционных условиях.

Инженерия применения

Для строительства зданий и мостов R260 обеспечивает отличное соотношение прочности и веса и превосходную свариваемость. В производстве машин и строительстве транспортных средств его улучшенная формуемость и усталостная стойкость обеспечивают надежную работу. Для общих инженерных приложений сбалансированные механические свойства стали и устойчивость к атмосферной коррозии делают ее идеальной для различных конструкционных требований.

🧪 Chemical Composition

| Элемент | Состав (%) |

|---|---|

| Углерод (C) | ≤ 0.20 |

| Марганец (Mn) | 1.20 - 1.70 |

| Кремний (Si) | 0.15 - 0.55 |

| Фосфор (P) | ≤ 0.030 |

| Сера (S) | ≤ 0.025 |

| Алюминий (Al) | ≥ 0.015 |

| Ниобий (Nb) | 0.015 - 0.060 |

| Титан (Ti) | 0.010 - 0.050 |

⚙️ Mechanical Properties

| Свойство | Значение |

|---|---|

| Предельная прочность (МПа) | ≥ 260 |

| Тянущая прочность (МПа) | 370 - 510 |

| Удлинение (%) | ≥ 26 |

| Энергия удара при 0°C (Дж) | ≥ 27 |

| Твердость (HB) | 120 - 160 |

| Прочность на усталость (МПа) | ≥ 180 |

🔬 Physical Properties

| Свойство | Значение |

|---|---|

| Плотность (г/см3) | 7.85 |

| Температура плавления (°C) | 1510 - 1540 |

| Теплопроводность (Вт/м·К) | 50.2 |

| Тепловое расширение (×10??/К) | 11.8 |

| Модуль упругости (ГПа) | 210 |

| Коэффициент Пуассона | 0.30 |

📏 Product Specifications

| Спецификация | Детали |

|---|---|

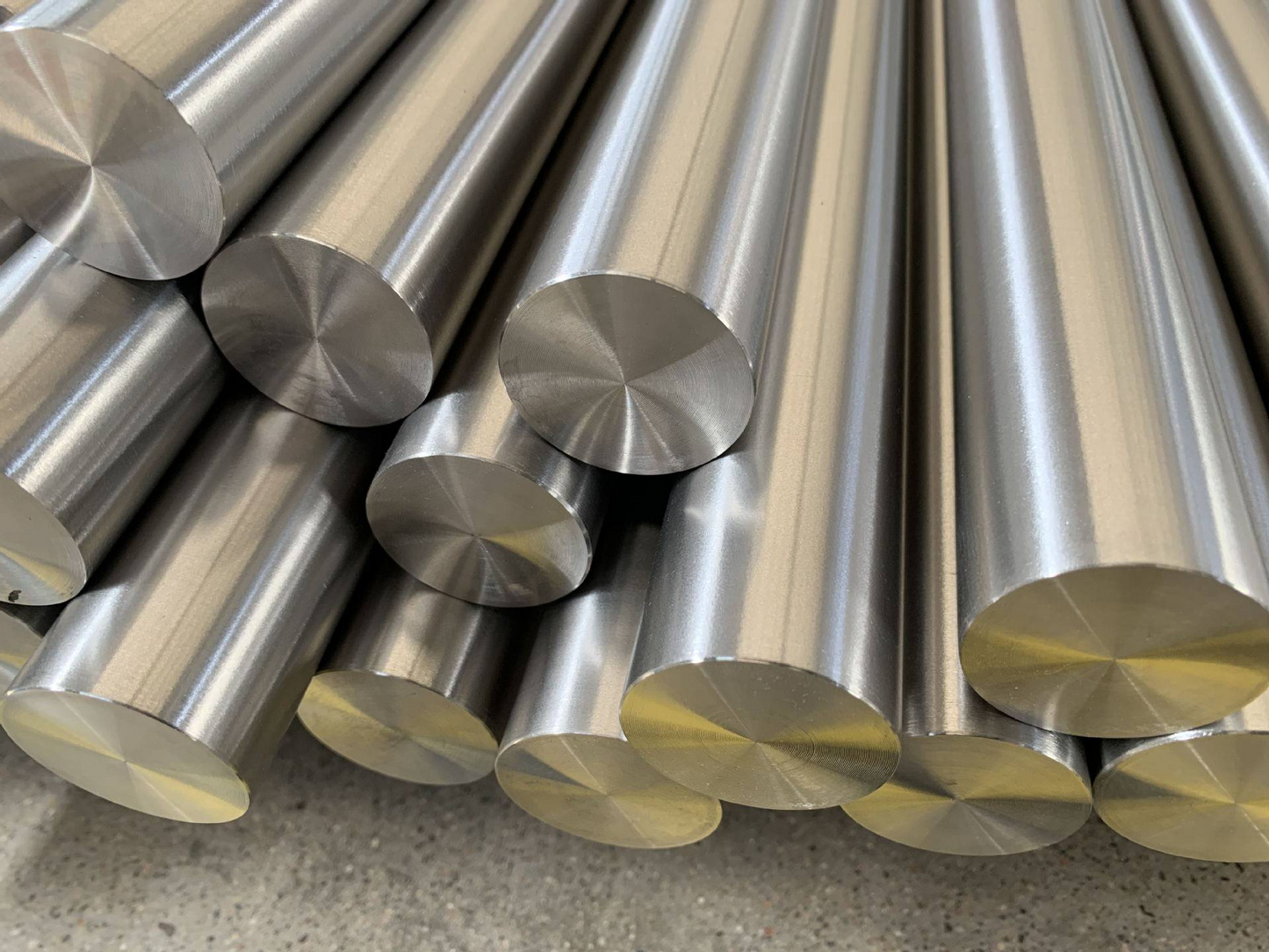

| Доступные формы | Пластины, Листы, Балки, Каналы, Уголки, Бруски |

| Диапазон толщины | 3 - 80мм |

| Диапазон ширины | 1000 - 3500мм |

| Диапазон длины | 6000 - 15000мм |

| Соответствие стандартам | ASTM A572, EN 10025-2, JIS G3106 |

| Условия термообработки | Горячекатаный или Нормализованный |

| Поверхностная отделка | Мельничный масштаб, Кислотная обработка, Стрельба по песку |

Давайте создадим успех для вашего проекта

Профессиональная команда, премиум-продукты, полный сервис - успех вашего проекта является нашей миссией

Our Advantages in Processing Сталь R260

Продвинутая термомеханическая обработка

MetalZenith использует контролируемую прокатку и точную термомеханическую обработку с мониторингом микроструктуры в реальном времени для достижения оптимальной зернистой структуры и улучшенных механических свойств. Наша передовая обработка обеспечивает превосходное соотношение прочности к весу и отличную формуемость на протяжении всей толщины материала.

Комплексное структурное тестирование

Наш сталь R260 проходит обширные испытания, включая оценку сварочной производительности, оценку формуемости, испытания на усталостную прочность и анализ устойчивости к атмосферной коррозии. Эти комплексные испытания обеспечивают оптимальную производительность в требовательных структурных приложениях.

Пользовательские решения по изготовлению

MetalZenith предоставляет полные услуги по индивидуальной обработке, включая точное резание, формование и оптимизацию термической обработки. Наша техническая команда предлагает экспертные консультации по требованиям к структурному дизайну и проблемам производства.

ВАШ НАДЕЖНЫЙ СТАЛЬ

ПАРТНЕР ПО ПРОИЗВОДСТВУ

Быстрый запрос

Отрасли, которые мы обслуживаем

Профессиональные стальные решения для основных отраслей

Квалификации и сертификаты