20 лет опыта | 1000+ партнеров по брендам | Полная настройка

У нас 20 лет опыта в отрасли, мы сотрудничаем с более чем 1,000 брендами и поддерживаем любые потребности в настройке.

Technical Specifications

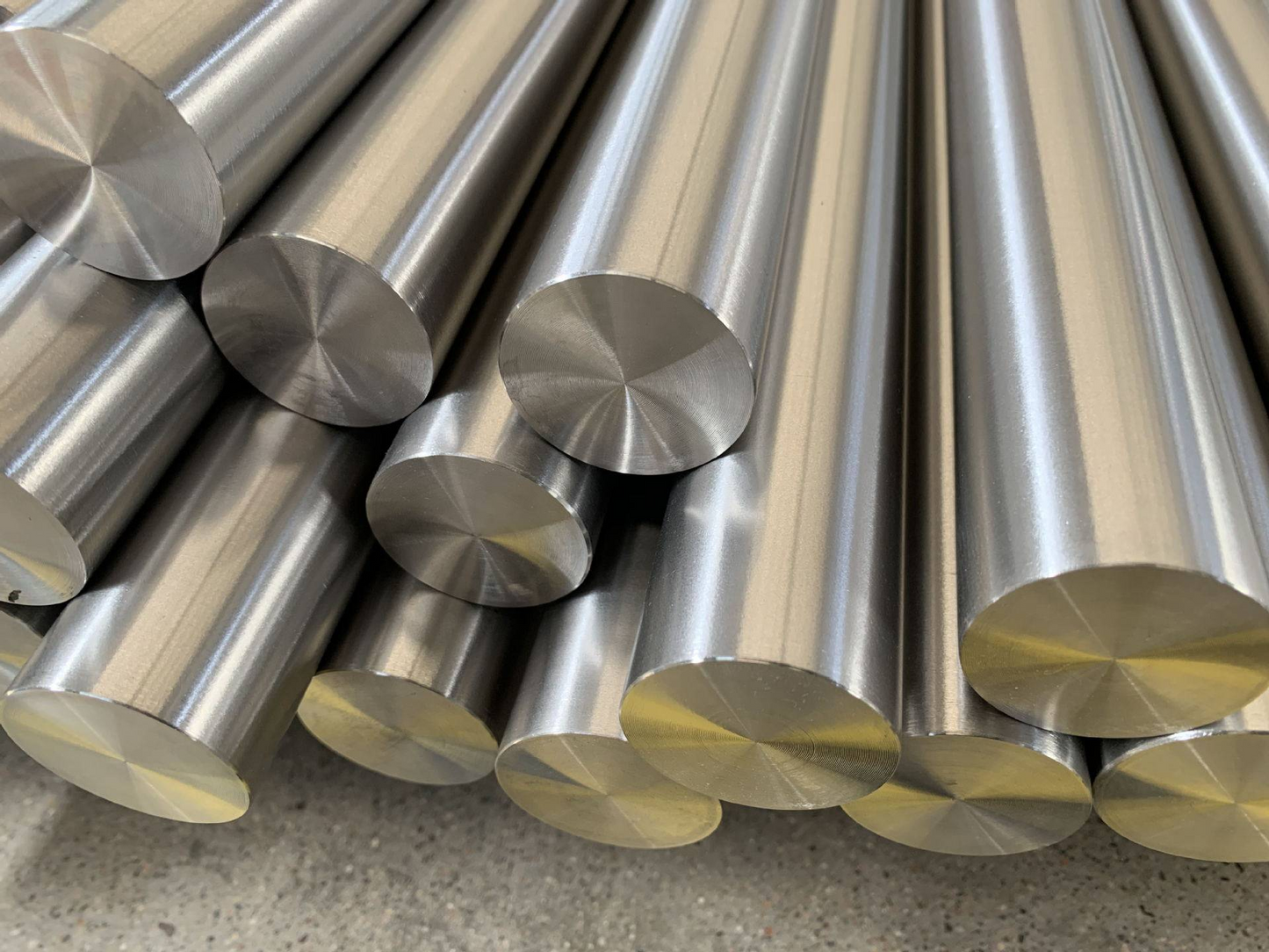

Product Overview

Металлургические характеристики

Q235 - это низкоуглеродная конструкционная сталь с преимущественно ферритно-перлитной микроструктурой. Контролируемое содержание углерода обеспечивает отличную свариваемость при сохранении достаточной прочности для конструкционных приложений. Мелкозернистая структура, достигнутая благодаря контролируемой прокатке, обеспечивает оптимальный баланс между прочностью, пластичностью и ударной вязкостью для общего строительного использования.

Процесс термообработки

MetalZenith использует контролируемую горячую прокатку при температурах от 1050 до 1200°C, за которой следует контролируемое охлаждение для достижения оптимальных механических свойств. Дополнительная нормализация при 860-920°C может быть применена для улучшения зернистости и повышения ударной вязкости, когда это указано для критических конструкционных приложений.

Процесс производства

Наше производство Q235 использует электрошлаковую плавку стали с вторичной переработкой для точного контроля химического состава. Современное непрерывное литье обеспечивает однородную структуру, в то время как наши многопрокатные горячие станы с компьютерным управлением процессом обеспечивают постоянные механические свойства и точность размеров на протяжении всего рулона или листа.

Специализированное качество тестирования

MetalZenith проводит комплексные тестовые протоколы, специфичные для конструкционных приложений, включая тестирование свариваемости по AWS D1.1, испытания на изгиб для оценки формуемости, испытания на усталость вращающейся балки для оценки производительности при циклических нагрузках и испытания на солевом распылении для оценки устойчивости к атмосферной коррозии, обеспечивая оптимальную производительность в различных конструкционных условиях.

Соображения по инженерному применению

Для строительства зданий отличная свариваемость Q235 позволяет эффективно изготавливать сложные конструкционные соединения. В мостостроении усталостная прочность стали и свойства атмосферной коррозии обеспечивают долгосрочную долговечность. Для производства машин формуемость материала позволяет экономически эффективно производить рамы и корпуса. В производстве транспортных средств Q235 обеспечивает оптимальное соотношение прочности и веса для компонентов шасси, в то время как его общая инженерная универсальность делает его идеальным для различных производственных приложений, требующих надежных механических свойств и характеристик обработки.

🧪 Chemical Composition

| Элемент | Состав (%) |

|---|---|

| Углерод (C) | ≤ 0.22 |

| Марганец (Mn) | 0.30 - 0.70 |

| Кремний (Si) | ≤ 0.35 |

| Фосфор (P) | ≤ 0.045 |

| Сера (S) | ≤ 0.050 |

| Железо (Fe) | Остальное |

⚙️ Mechanical Properties

| Свойство | Значение |

|---|---|

| Предельная прочность (МПа) | ≥ 235 |

| Тянущая прочность (МПа) | 370 - 500 |

| Удлинение (%) | ≥ 26 |

| Энергия удара при 20°C (Дж) | ≥ 27 |

| Твердость (HB) | 120 - 160 |

| Выносливость (МПа) | 180 - 220 |

🔬 Physical Properties

| Свойство | Значение |

|---|---|

| Плотность (г/см3) | 7.85 |

| Температура плавления (°C) | 1510 - 1540 |

| Теплопроводность (Вт/м·К) | 49.8 |

| Тепловое расширение (×10??/K) | 12.0 |

| Модуль упругости (ГПа) | 200 - 210 |

| Коэффициент Пуассона | 0.27 - 0.30 |

📏 Product Specifications

| Спецификация | Детали |

|---|---|

| Доступные формы | Пластины, Листы, Бруски, Углы, Каналы, Балки |

| Диапазон толщины | 1.5 - 200мм |

| Диапазон ширины | 600 - 3500мм |

| Диапазон длины | 2000 - 12000мм |

| Соответствие стандартам | GB/T 700, ASTM A36, JIS G3101 SS400 |

| Состояние поверхности | Горячекатаный, Очищенный, Стреляный |

| Условия поставки | Горячекатаный, Нормализованный (по желанию) |

Давайте создадим успех для вашего проекта

Профессиональная команда, премиум-продукты, полный сервис - успех вашего проекта является нашей миссией

Our Advantages in Processing Сталь Q235

Контролируемая технология горячей прокатки

MetalZenith использует передовые технологии контролируемой горячей прокатки с точным мониторингом температуры и контролем скорости охлаждения для достижения оптимального упрочнения зерна и механических свойств. Наши современные прокатные станы обеспечивают постоянную толерантность по толщине и превосходное качество поверхности, улучшая формуемость и свариваемость стали для строительных применений.

Комплексное структурное тестирование

Наш сталь Q235 проходит обширные испытательные протоколы, включая оценку свариваемости в соответствии со стандартами AWS, испытания на изгиб для оценки формуемости, испытания на усталостную прочность при циклической нагрузке и ускоренные испытания на атмосферную коррозию. Эти комплексные испытания обеспечивают оптимальную производительность в сложных структурных условиях.

Услуги по индивидуальному изготовлению

MetalZenith предоставляет полные услуги по индивидуальной обработке, включая точное резание, формование, подготовку к сварке и обработку поверхности. Наша техническая команда предлагает инженерную поддержку для оптимизации структурного дизайна, обеспечивая соответствие спецификациям стали Q235 конкретным требованиям проекта для строительных и производственных приложений.

ВАШ НАДЕЖНЫЙ СТАЛЬ

ПАРТНЕР ПО ПРОИЗВОДСТВУ

Быстрый запрос

Отрасли, которые мы обслуживаем

Профессиональные стальные решения для основных отраслей

Квалификации и сертификаты