20 лет опыта | 1000+ партнеров по брендам | Полная настройка

У нас 20 лет опыта в отрасли, мы сотрудничаем с более чем 1,000 брендами и поддерживаем любые потребности в настройке.

Technical Specifications

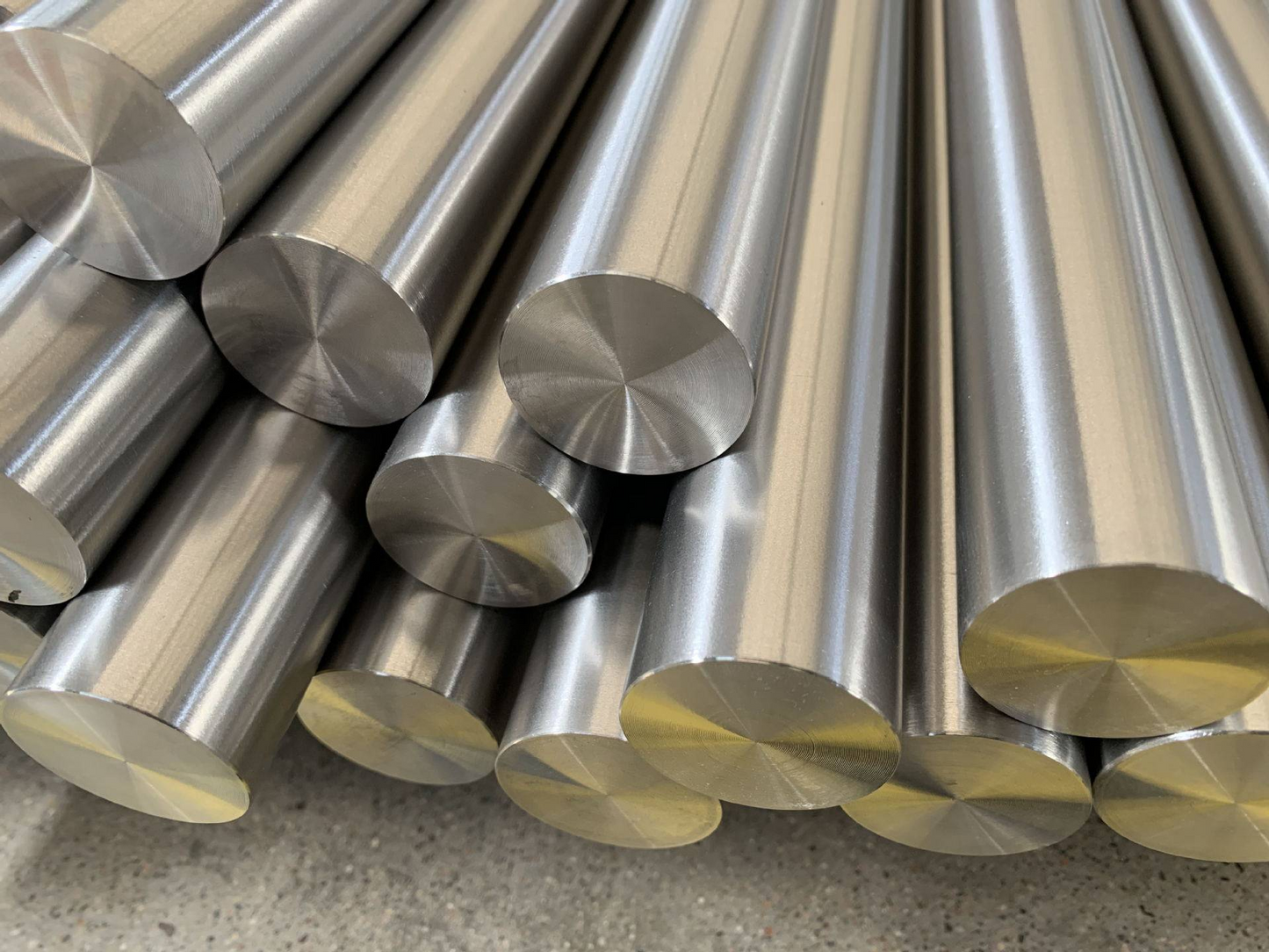

Product Overview

Металлургические характеристики

Сталь EN24 обладает закаленной мартенситной микроструктурой с мелким осаждением карбидов, достигнутой благодаря контролируемым процессам закалки и отжига. Система легирования на основе никеля, хрома и молибдена обеспечивает отличную закаливаемость и прочность, сохраняя при этом высокие уровни прочности, необходимые для конструктивных применений. Сбалансированный состав сплава обеспечивает однородные механические свойства по всей толщине.

Процесс термообработки

MetalZenith использует контролируемое аустенитирование при 850-870°C, за которым следует закалка в масле для достижения оптимальной твердости. Последующий отжиг при 550-650°C развивает необходимый баланс прочности и вязкости. Наш точный контроль температуры и управление скоростью охлаждения обеспечивают стабильные механические свойства и минимизируют остаточные напряжения, критически важные для структурной целостности.

Производственное совершенство

Наше производство EN24 использует плавку в электродуговой печи с последующими процессами рафинирования, включая металлургию в ковше и вакуумное дегазирование. Контролируемые операции ковки с оптимизированными коэффициентами уменьшения обеспечивают отличную зернистую структуру и однородность механических свойств. Современные методы неразрушающего контроля, включая ультразвуковую инспекцию, гарантируют внутреннюю целостность.

Тестирование структурной производительности

MetalZenith проводит комплексные протоколы тестирования, включая испытания на ударную вязкость по Шарпи с V-образным вырезом при различных температурах, испытания на усталостную прочность с вращающейся балкой, оценку свариваемости с использованием стандартных процедур и ускоренное тестирование атмосферной коррозии. Наша оценка производительности формовки включает испытания на изгиб и оценки холодной обработки для обеспечения пригодности для процессов конструктивного производства.

Инженерные приложения

Исключительное соотношение прочности к весу EN24 делает его идеальным для строительства конструктивных каркасов, требующих высокой несущей способности. В мостостроении его усталостная прочность обеспечивает долговечность при циклических нагрузках. Для автомобильных приложений прочность и обрабатываемость материала позволяют создавать сложные геометрии компонентов. В тяжелом оборудовании EN24 обеспечивает надежную работу при экстремальных эксплуатационных нагрузках, сохраняя при этом размерную стабильность.

🧪 Chemical Composition

| Элемент | Состав (%) |

|---|---|

| Углерод (C) | 0.36 - 0.44 |

| Марганец (Mn) | 0.45 - 0.70 |

| Кремний (Si) | 0.10 - 0.40 |

| Фосфор (P) | ≤ 0.035 |

| Сера (S) | ≤ 0.040 |

| Никель (Ni) | 1.30 - 1.70 |

| Хром (Cr) | 1.00 - 1.40 |

| Молибден (Mo) | 0.20 - 0.35 |

⚙️ Mechanical Properties

| Свойство | Значение |

|---|---|

| Предельная прочность (МПа) | ≥ 775 |

| Тянущая прочность (МПа) | 925 - 1175 |

| Удлинение (%) | ≥ 12 |

| Энергия удара при 20°C (Дж) | ≥ 47 |

| Твердость (HB) | 280 - 340 |

| Прочность на усталость (МПа) | 450 - 500 |

🔬 Physical Properties

| Свойство | Значение |

|---|---|

| Плотность (г/см3) | 7.85 |

| Температура плавления (°C) | 1420 - 1460 |

| Теплопроводность (Вт/м·К) | 42.7 |

| Тепловое расширение (×10??/К) | 12.3 |

| Модуль упругости (ГПа) | 210 |

| Коэффициент Пуассона | 0.27 - 0.30 |

📏 Product Specifications

| Спецификация | Детали |

|---|---|

| Доступные формы | Круглые прутки, Квадратные прутки, Плоские прутки, Плиты, Ковка |

| Диапазон диаметра | 10 - 500мм |

| Диапазон толщины | 5 - 200мм |

| Диапазон длины | 1000 - 12000мм |

| Соответствие стандартам | BS 970 Grade 817M40, ASTM A322, DIN 1.6511 |

| Условия термообработки | Закаленный и отпущенный |

| Обработка поверхности | Черный, Обработанный, Шлифованный, Полированный |

Давайте создадим успех для вашего проекта

Профессиональная команда, премиум-продукты, полный сервис - успех вашего проекта является нашей миссией

Our Advantages in Processing Сталь EN24

Технология прецизионной термической обработки

MetalZenith использует современные печи с контролируемой атмосферой, с точным мониторингом температуры и автоматизированными системами закалки для достижения оптимального распределения твердости в стали EN24. Наш запатентованный процесс отпускания обеспечивает постоянные механические свойства и повышенную структурную целостность по всей толщине материала.

Комплексное структурное тестирование

Наш сталь EN24 проходит обширные испытания, включая испытания на ударную вязкость по Шарпи, оценку прочности на усталость, оценку сварочной производительности и испытания на атмосферную коррозионную стойкость. Передовые протоколы испытаний MetalZenith обеспечивают превосходные характеристики в структурных приложениях с документированным соответствием международным стандартам.

Пользовательские инженерные решения

MetalZenith предлагает индивидуальные решения из стали EN24 с учетом специфики термической обработки, услуги прецизионной механической обработки и всестороннюю техническую поддержку. Наша инженерная команда сотрудничает с клиентами для оптимизации свойств материалов для конкретных структурных приложений и требований к производительности.

ВАШ НАДЕЖНЫЙ СТАЛЬ

ПАРТНЕР ПО ПРОИЗВОДСТВУ

Быстрый запрос

Отрасли, которые мы обслуживаем

Профессиональные стальные решения для основных отраслей

Квалификации и сертификаты