20 лет опыта | 1000+ партнеров по брендам | Полная настройка

У нас 20 лет опыта в отрасли, мы сотрудничаем с более чем 1,000 брендами и поддерживаем любые потребности в настройке.

Technical Specifications

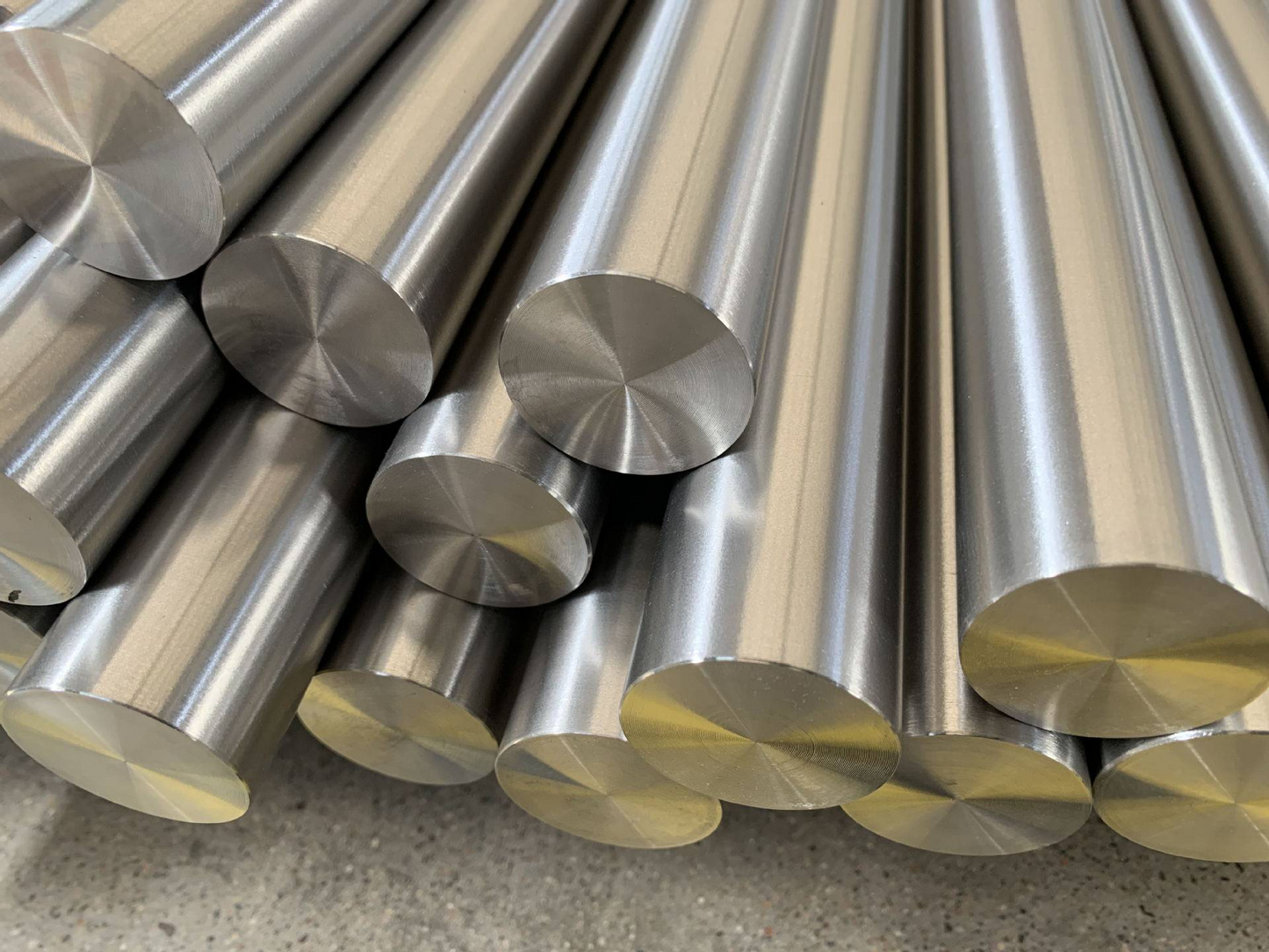

Product Overview

Металлургические характеристики

EN 1.4541 - это аустенитная нержавеющая сталь, стабилизированная титаном для предотвращения межкристаллической коррозии в температурном диапазоне 425-815°C. Содержание титана образует стабильные карбиды (TiC), которые предотвращают осаждение хромового карбида на границах зерен, сохраняя коррозионную стойкость даже после сварки или воздействия высоких температур. Аустенитная микроструктура обеспечивает отличную пластичность и прочность в широком температурном диапазоне.

Процесс термообработки

MetalZenith использует контролируемую атмосферу для решения отжига при 1050-1100°C с последующим быстрым охлаждением для достижения оптимальных свойств. Наши современные термообрабатывающие установки оснащены точным контролем температуры (±5°C) и системами защитной атмосферы для предотвращения окисления и декарбонизации. После отжига может быть применено снятие напряжений при 850-900°C для конкретных применений, требующих размерной стабильности.

Совершенство производственного процесса

Наш интегрированный производственный процесс начинается с плавки в электродуговой печи, за которой следует рафинирование AOD для точного контроля состава. Непрерывная литье обеспечивает однородную структуру, в то время как наши многопрокатные горячекатаные станы с компьютерным управлением процессом обеспечивают стабильные механические свойства. Возможности холодной обработки включают точное прокатывание, вытяжку и формовку с промежуточными циклами отжига для поддержания оптимальной микроструктуры.

Стандарты качества и испытания

Все продукты EN 1.4541 проходят комплексные испытания, включая оптическую эмиссионную спектроскопию для химического анализа, испытания на растяжение по ASTM A370, испытания на межкристаллическую коррозию по ASTM A262 Практика A и ультразвуковую инспекцию для проверки внутренней целостности. Наша система управления качеством обеспечивает соответствие требованиям сертификации EN 10204 3.1, обеспечивая полную прослеживаемость материалов от сырья до готовой продукции. Продвинутое металлографическое исследование подтверждает размер зерна, содержание включений и распределение фаз в соответствии со стандартами ASTM E112 и E45.

🧪 Chemical Composition

| Элемент | Состав (%) |

|---|---|

| Углерод (C) | ≤ 0.08 |

| Кремний (Si) | ≤ 1.00 |

| Марганец (Mn) | ≤ 2.00 |

| Фосфор (P) | ≤ 0.045 |

| Сера (S) | ≤ 0.030 |

| Хром (Cr) | 17.0 - 19.0 |

| Никель (Ni) | 9.0 - 12.0 |

| Титан (Ti) | 5×C - 0.70 |

| Азот (N) | ≤ 0.10 |

| Железо (Fe) | Баланс |

⚙️ Mechanical Properties

| Свойство | Значение |

|---|---|

| Устойчивость к растяжению (Rm) | 520 - 720 MPa |

| Предел текучести (Rp0.2) | ≥ 205 MPa |

| Удлинение (A5) | ≥ 40% |

| Твердость (HB) | ≤ 215 |

| Энергия удара (KV) | ≥ 60 J (при 20°C) |

| Модуль Юнга | 200 GPa |

| Предел усталости | 240 MPa (107 циклов) |

| Коэффициент Пуассона | 0.30 |

🔬 Physical Properties

| Свойство | Значение |

|---|---|

| Плотность | 7.90 g/cm³ |

| Температура плавления | 1400 - 1425°C |

| Теплопроводность (20°C) | 16.2 W/m·K |

| Тепловое расширение (20-100°C) | 16.6×10-6/K |

| Удельная теплоемкость | 500 J/kg·K |

| Электрическое сопротивление (20°C) | 0.72 µΩ·m |

| Магнитная проницаемость | 1.02 (немагнитный) |

| Тепловая диффузия | 4.1×10-6 m²/s |

📏 Product Specifications

| Спецификация | Доступные варианты |

|---|---|

| Формы продукта | Круглые прутки, плоские прутки, листы, пластины, трубы, трубы, проволока, кованые изделия |

| Диаметр круглого прутка | 6mm - 300mm |

| Размеры плоского прутка | 10×3mm - 150×50mm |

| Толщина листа | 0.4mm - 6.0mm |

| Толщина пластины | 6mm - 100mm |

| Внешний диаметр трубы | 6mm - 219mm |

| Стандарты | EN 10088, ASTM A240, A276, A312, JIS G4303, G4304 |

| Отделка поверхности | Горячекатаный, холоднокатаный, ярко отожженный, травленный, полированный |

| Класс допуска | h9, h11 (прутки), ±0.1mm (лист/пластины) |

Давайте создадим успех для вашего проекта

Профессиональная команда, премиум-продукты, полный сервис - успех вашего проекта является нашей миссией

Our Advantages in Processing EN 1.4541

Совершенная технология вакуумного плавления

MetalZenith использует современные процессы вакуумного индукционного плавления (VIM) и электрошлакового переплавления (ESR) для производства EN 1.4541 с исключительной чистотой и однородностью. Наша передовая технология плавления обеспечивает точный контроль стабилизации титана, что приводит к превосходным свойствам при высоких температурах и повышенной стойкости к межкристаллитной коррозии.

Комплексная система контроля качества

Наша интегрированная система управления качеством включает в себя современный спектроскопический анализ, автоматизированное механическое тестирование и мониторинг процессов в реальном времени. Каждая партия EN 1.4541 проходит строгие испытания, включая проверку химического состава, валидацию механических свойств и микроструктурное исследование, чтобы обеспечить стабильное качество и соответствие международным стандартам.

Пользовательская обработка и глобальная цепочка поставок

MetalZenith предлагает обширные возможности настройки, включая точную механическую обработку, специализированные термические обработки и индивидуальные размеры. Наша глобальная сеть поставок с стратегически расположенными складами обеспечивает быструю доставку по всему миру, в то время как наша команда технической поддержки предоставляет инженерную помощь для специфических требований приложений и оптимизации материалов.

ВАШ НАДЕЖНЫЙ СТАЛЬ

ПАРТНЕР ПО ПРОИЗВОДСТВУ

Быстрый запрос

Отрасли, которые мы обслуживаем

Профессиональные стальные решения для основных отраслей

Квалификации и сертификаты