20 лет опыта | 1000+ партнеров по брендам | Полная настройка

У нас 20 лет опыта в отрасли, мы сотрудничаем с более чем 1,000 брендами и поддерживаем любые потребности в настройке.

Technical Specifications

Product Overview

Металлургические характеристики

AISI 304H - это аустенитная нержавеющая сталь с кубической кристаллической решеткой с центром на грани. Более высокое содержание углерода (0.04-0.10%) по сравнению со стандартным классом 304 обеспечивает повышенную стойкость к ползучести и улучшенные механические свойства при повышенных температурах. Аустенитная микроструктура стабилизируется сбалансированным составом хрома и никеля, что обеспечивает отличную коррозионную стойкость и формуемость.

Процесс термообработки

MetalZenith использует контролируемый отжиг раствора при температурах от 1040 до 1120°C, за которым следует быстрое охлаждение для достижения оптимальной микроструктуры. Этот процесс растворяет карбиды и обеспечивает однородную аустенитную структуру по всему материалу. Контролируемая скорость охлаждения предотвращает сенсибилизацию и сохраняет свойства коррозионной стойкости.

Совершенство производственного процесса

Наш передовой производственный процесс начинается с тщательно отобранного сырья, расплавленного в электродуговых печах с точным контролем температуры и атмосферы. Вторичные процессы рафинирования, включая AOD (декарбонизация с использованием аргона и кислорода), обеспечивают оптимальный химический состав и чистоту. Горячая прокатка, холодная прокатка и операции прецизионной отделки выполняются под строгим контролем качества для достижения желаемых механических свойств и отделки поверхности.

Стандарты качества и испытания

MetalZenith соблюдает международные стандарты, включая ASTM A240, EN 10088-2 и JIS G4305. Комплексные протоколы испытаний включают химический анализ с использованием оптической эмиссионной спектрометрии, механические испытания в соответствии со стандартами ASTM, испытания на межзерновую коррозию (ASTM A262) и неразрушающий контроль, включая ультразвуковое тестирование и инспекцию с использованием проникающих красителей.

Коррозионная стойкость и производительность

Содержание хрома 18-20% обеспечивает отличную общую коррозионную стойкость, в то время как 8-10.5% никеля гарантирует аустенитную стабильность и повышенную стойкость к коррозионному растрескиванию под напряжением. AISI 304H демонстрирует превосходную производительность в окисляющих средах и сохраняет структурную целостность при температурах до 870°C в непрерывном режиме работы.

🧪 Chemical Composition

| Элемент | Состав (%) |

|---|---|

| Углерод (C) | 0.04 - 0.10 |

| Марганец (Mn) | ≤ 2.00 |

| Кремний (Si) | ≤ 0.75 |

| Фосфор (P) | ≤ 0.045 |

| Сера (S) | ≤ 0.030 |

| Хром (Cr) | 18.0 - 20.0 |

| Никель (Ni) | 8.0 - 10.5 |

| Азот (N) | ≤ 0.10 |

| Железо (Fe) | Баланс |

⚙️ Mechanical Properties

| Свойство | Значение |

|---|---|

| Предельная прочность на растяжение (мин) | 515 MPa |

| Предельная прочность 0.2% смещения (мин) | 205 MPa |

| Удлинение на 50 мм (мин) | 40% |

| Снижение площади (мин) | 50% |

| Твердость (Бринелль) | ≤ 201 HB |

| Твердость (Роквелл B) | ≤ 92 HRB |

| Энергия удара (Шарпи V-образный надрез при 20°C) | ≥ 120 J |

| Предельная усталостная прочность (10^7 циклов) | 240 MPa |

| Модуль упругости | 200 GPa |

🔬 Physical Properties

| Свойство | Значение |

|---|---|

| Плотность | 8.00 g/cm³ |

| Температура плавления | 1400-1450°C |

| Теплопроводность (при 100°C) | 16.2 W/m·K |

| Коэффициент теплового расширения (20-100°C) | 17.2×10-6/K |

| Удельная теплоемкость | 500 J/kg·K |

| Электрическое сопротивление (при 20°C) | 0.72 µΩ·m |

| Магнитная проницаемость | 1.02 (Немагнитный) |

| Тепловая диффузия | 4.2×10-6 m²/s |

| Температура Кюри | N/A (Аустенитный) |

📏 Product Specifications

| Спецификация | Доступные варианты |

|---|---|

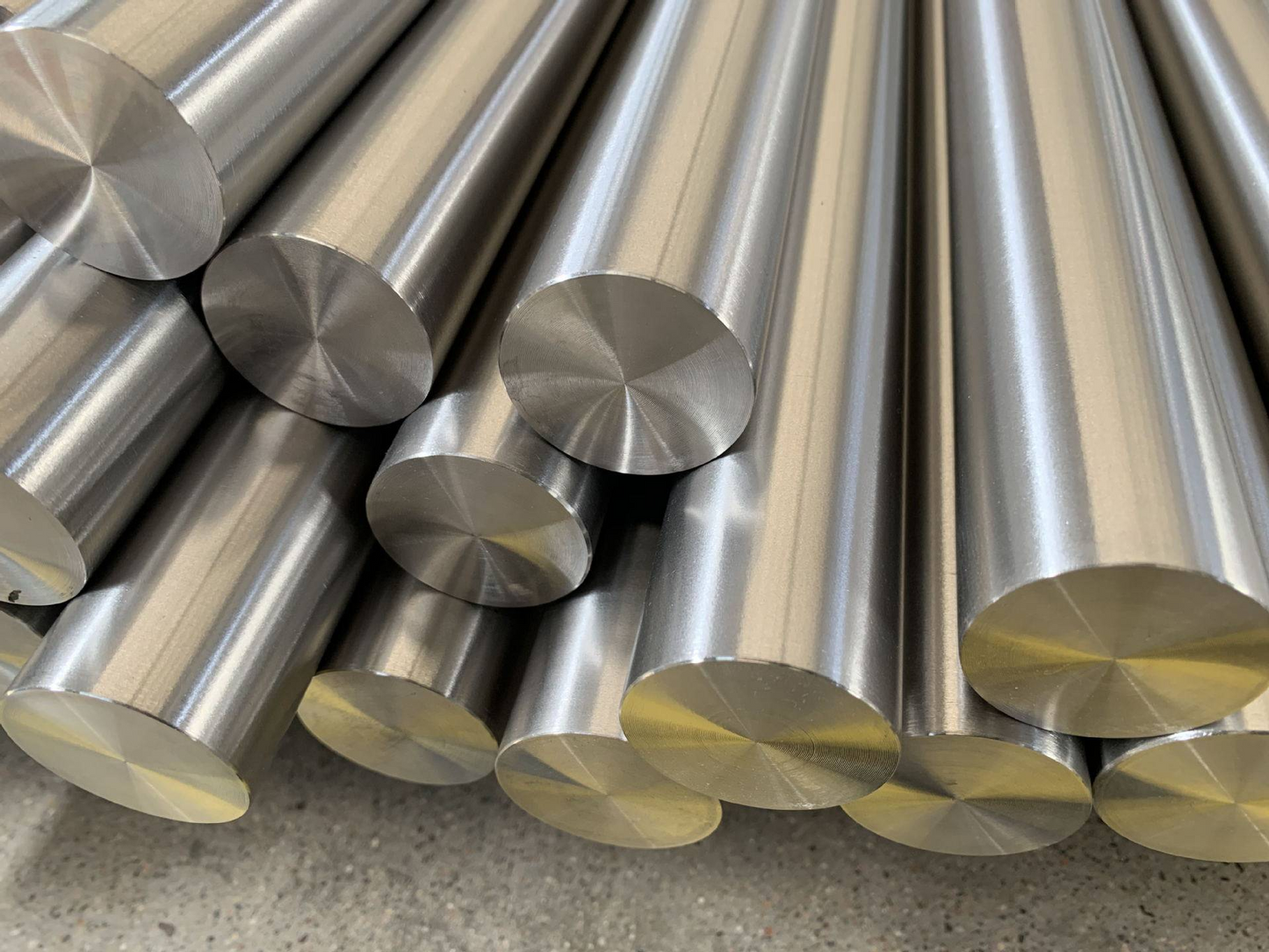

| Формы продукта | Пластины, Листы, Катушки, Бруски, Стержни, Трубки, Трубы, Ковки |

| Толщина пластины | 6mm - 200mm |

| Толщина листа | 0.4mm - 6mm |

| Диаметр бруска | 6mm - 300mm |

| Внешний диаметр трубки | 6mm - 610mm |

| Стандарты | ASTM A240, A479, A312, EN 10088-2, JIS G4305, GB/T 3280 |

| Обработка поверхности | 2B, BA, No.4, HL (Hairline), Зеркало, Кислотная |

| Допуск | ±0.1mm (толщина), ±3mm (ширина), ±6mm (длина) |

| Состояние края | Мельничный край, Резанный край, Обрезанный край |

| Термическая обработка | Отжиг в растворе (1040-1120°C) |

Давайте создадим успех для вашего проекта

Профессиональная команда, премиум-продукты, полный сервис - успех вашего проекта является нашей миссией

Our Advantages in Processing AISI 304H

Современные технологии электродуговых печей

MetalZenith использует передовые технологии электродуговых печей с точным контролем температуры и современными процессами рафинирования для достижения оптимального содержания углерода (0.04-0.10%) в AISI 304H, обеспечивая превосходное сопротивление ползучести при высоких температурах и механические свойства.

Комплексная система контроля качества

Наша современная испытательная лаборатория оснащена передовыми спектрометрами, универсальными испытательными машинами и металлографическим оборудованием. Каждая партия проходит строгий химический анализ, механическое испытание и микроструктурное исследование для обеспечения соответствия международным стандартам.

Индивидуальная обработка и глобальное распределение

MetalZenith предлагает обширные возможности настройки, включая точную резку, отделку поверхности и услуги термообработки. Наша глобальная сеть распределения обеспечивает своевременную доставку по всему миру с комплексной технической поддержкой и консультационными услугами в области инженерии.

ВАШ НАДЕЖНЫЙ СТАЛЬ

ПАРТНЕР ПО ПРОИЗВОДСТВУ

Быстрый запрос

Отрасли, которые мы обслуживаем

Профессиональные стальные решения для основных отраслей

Квалификации и сертификаты