20 лет опыта | 1000+ партнеров по брендам | Полная настройка

У нас 20 лет опыта в отрасли, мы сотрудничаем с более чем 1,000 брендами и поддерживаем любые потребности в настройке.

Technical Specifications

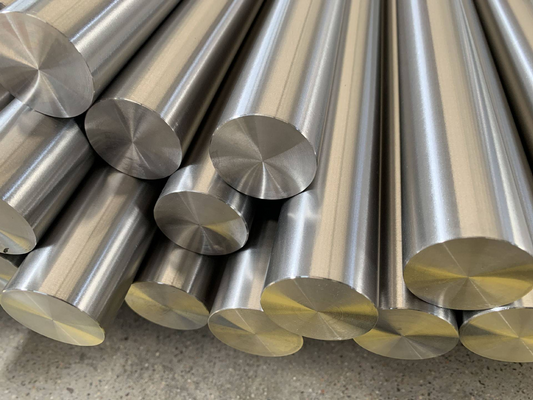

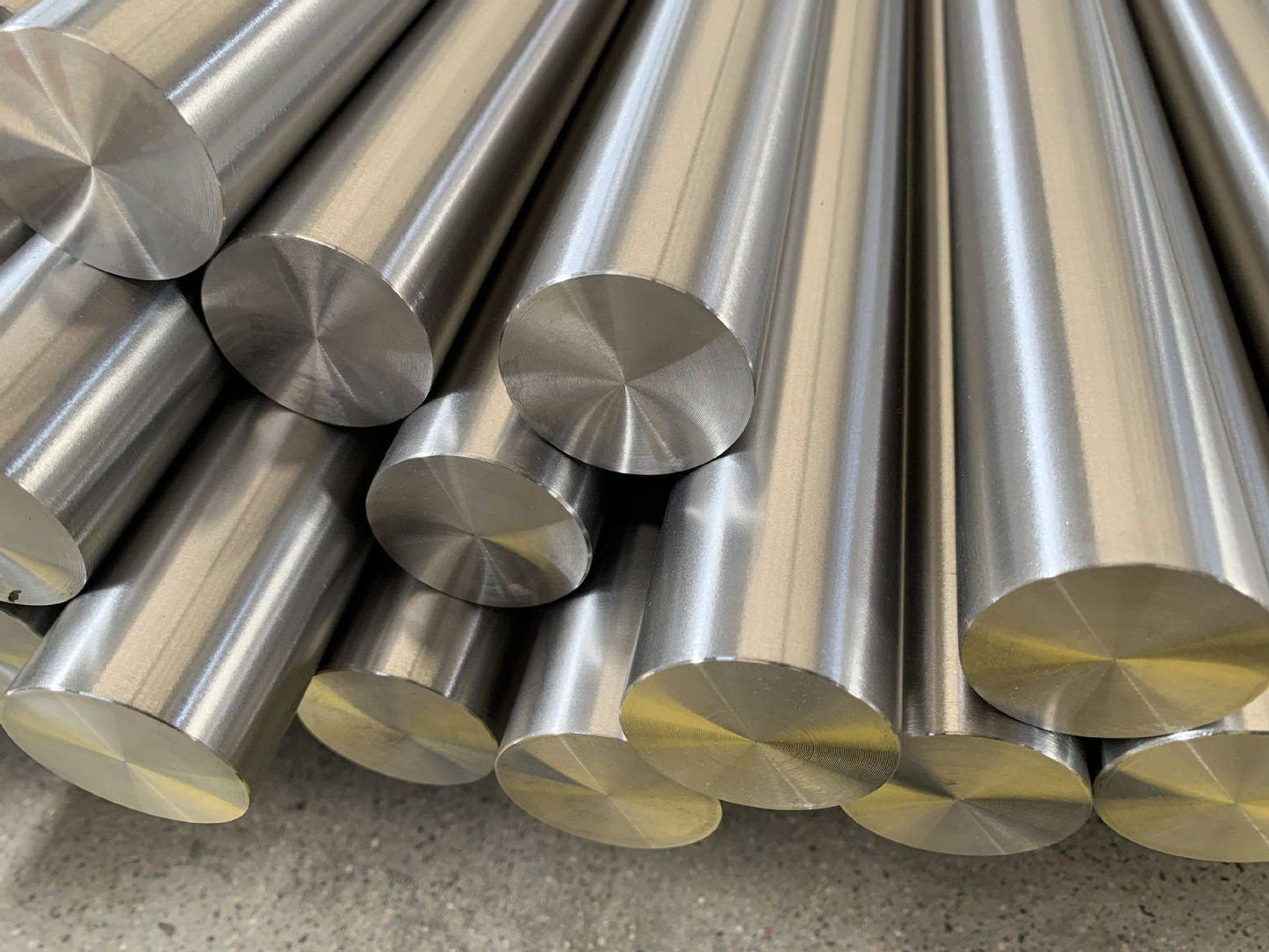

Product Overview

Металлургические характеристики

Сталь трубопровода GB L245 имеет мелкозернистую микроструктуру феррит-перлита, достигнутую благодаря контролируемой прокатке и ускоренному охлаждению. Низкое содержание углерода (≤ 0.28%) обеспечивает отличную свариваемость при сохранении адекватного уровня прочности. Микролегирующие элементы, такие как ванадий и ниобий, обеспечивают упрочнение зерна и осаждение, улучшая как прочностные, так и ударные свойства.

Термическая обработка и переработка

MetalZenith использует термомеханическую контролируемую переработку (TMCP) для производства GB L245, включая контролируемую прокатку в области рекристаллизации аустенита и нерекристаллизованных областях, за которой следует ускоренное охлаждение. Этот процесс устраняет необходимость в последующей термической обработке, достигая превосходных механических свойств. Нормализация при 900-950°C может быть применена для снятия напряжений при необходимости.

Совершенство производственного процесса

Наш интегрированный завод по производству стали использует электросталеплавильное производство с рафинированием в ковше и вакуумным дегазацией для достижения точного контроля химического состава. Непрерывная литье обеспечивает равномерную затвердевание и минимальную сегрегацию. Горячая прокатка выполняется с использованием компьютеризированных прокатных станов с точным контролем температуры и деформации для оптимизации развития микроструктуры.

Стандарты качества и сертификаты

Все продукты GB L245, произведенные MetalZenith, соответствуют стандартам GB/T 9711, API 5L PSL1/PSL2 и EN 10208. Наша система управления качеством сертифицирована по ISO 9001:2015, ISO 14001:2015 и OHSAS 18001. Каждая партия продукта включает в себя полные сертификаты испытаний на заводе с полной документацией по прослеживаемости, отчетами о химическом анализе и результатами проверки механических свойств.

🧪 Chemical Composition

| Элемент | Состав (%) |

|---|---|

| Углерод (C) | ≤ 0.28 |

| Марганец (Mn) | ≤ 1.20 |

| Кремний (Si) | ≤ 0.40 |

| Фосфор (P) | ≤ 0.030 |

| Сера (S) | ≤ 0.030 |

| Хром (Cr) | ≤ 0.30 |

| Никель (Ni) | ≤ 0.30 |

| Молибден (Mo) | ≤ 0.15 |

| Медь (Cu) | ≤ 0.50 |

| Ванадий (V) | ≤ 0.06 |

| Ниобий (Nb) | ≤ 0.05 |

| Титан (Ti) | ≤ 0.04 |

⚙️ Mechanical Properties

| Свойство | Значение |

|---|---|

| Предельная прочность (Rp0.2) | 245-450 MPa |

| Тянущая прочность (Rm) | 415-565 MPa |

| Удлинение (A) | ≥ 22% |

| Соотношение предельной к тянущей прочности | ≤ 0.93 |

| Твердость (HB) | 120-180 |

| Энергия удара (KV2) при 0°C | ≥ 27 J |

| Энергия удара (KV2) при -20°C | ≥ 20 J |

| Предельная усталостная прочность (10^7 циклов) | 180-220 MPa |

| Модуль упругости | 210 GPa |

| Коэффициент Пуассона | 0.27-0.30 |

| Сдвиговой модуль | 80 GPa |

🔬 Physical Properties

| Свойство | Значение |

|---|---|

| Плотность | 7.85 g/cm³ |

| Температура плавления | 1510-1540°C |

| Теплопроводность (20°C) | 54 W/m·K |

| Коэффициент теплового расширения (20-100°C) | 12×10-6/K |

| Удельная теплоемкость | 500 J/kg·K |

| Электрическое сопротивление (20°C) | 0.16 µΩ·m |

| Магнитная проницаемость | Ферромагнитный |

| Температура Кюри | 770°C |

| Тепловая диффузия | 13.7 mm²/s |

| Эмиссия (окисленная поверхность) | 0.79 |

📏 Product Specifications

| Спецификация | Детали |

|---|---|

| Доступные формы | Бесшовные трубы, Сварные трубы, Плиты, Листы, Катушки, Бруски |

| Диапазон диаметра трубы | 21.3mm - 1422mm (0.84' - 56') |

| Толщина стенки | 2.0mm - 80mm |

| Толщина плиты | 6mm - 200mm |

| Диапазон ширины | 1000mm - 4000mm |

| Диапазон длины | 6000mm - 18000mm |

| Соответствие стандартам | GB/T 9711, API 5L, EN 10208, ISO 3183 |

| Обработка поверхности | Черный, Кислотный, Масляный, Гальванизированный, Эпоксидное покрытие |

| Подготовка концов | Прямой конец, Скошенный конец, Резьбовой |

| Допуск по размерам | ±0.5% (Диаметр), ±10% (Толщина стенки) |

| Требования к испытаниям | Гидростатическое испытание, Неразрушающий контроль, Химический анализ, Механические испытания |

Давайте создадим успех для вашего проекта

Профессиональная команда, премиум-продукты, полный сервис - успех вашего проекта является нашей миссией

Our Advantages in Processing GB L245

Продвинутая термомеханическая обработка

MetalZenith использует современные технологии контролируемой прокатки и ускоренного охлаждения для достижения оптимального упрочнения зерна и улучшенных механических свойств стали GB L245, обеспечивая превосходную прочность и однородную микроструктуру по всей толщине материала.

Комплексная система контроля качества

Наша интегрированная система управления качеством включает в себя мониторинг химического состава в реальном времени, автоматизированное механическое тестирование и современные методы неразрушающего контроля, включая ультразвуковое тестирование и магнитно-частицкий контроль, чтобы гарантировать стабильное качество и надежность продукции.

Гибкая настройка и глобальная поставка

MetalZenith предлагает обширные возможности настройки, включая специализированные термические обработки, точную механическую обработку и индивидуальные размеры. Наша глобальная логистическая сеть обеспечивает своевременную доставку по всему миру с комплексной технической поддержкой и услугами инженерного консультирования.

ВАШ НАДЕЖНЫЙ СТАЛЬ

ПАРТНЕР ПО ПРОИЗВОДСТВУ

Быстрый запрос

Отрасли, которые мы обслуживаем

Профессиональные стальные решения для основных отраслей

Квалификации и сертификаты