20 лет опыта | 1000+ партнеров по брендам | Полная настройка

У нас 20 лет опыта в отрасли, мы сотрудничаем с более чем 1,000 брендами и поддерживаем любые потребности в настройке.

Technical Specifications

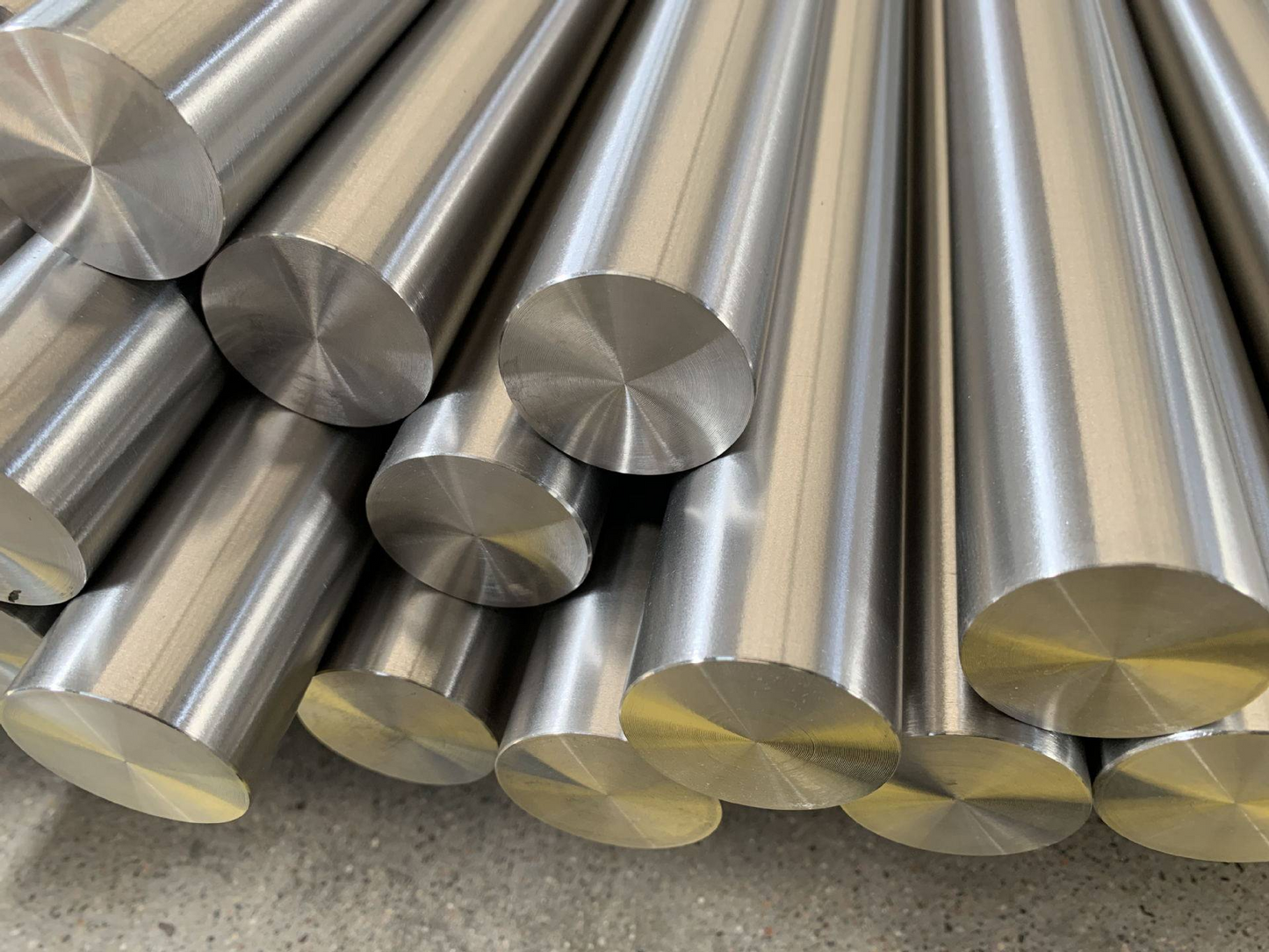

Product Overview

Металлургические характеристики

EN L485 - это микроалюминированная сталь с мелкозернистой микроструктурой феррит-цементит, достигнутой благодаря контролируемой прокатке и ускоренному охлаждению. Добавление ниобия и ванадия обеспечивает упрочнение за счет осаждения и улучшение зернистости, что приводит к отличному сочетанию прочности и ударной вязкости. Низкий эквивалент углерода (CE ≤ 0.43%) обеспечивает превосходную свариваемость без необходимости предварительного подогрева.

Процесс производства

MetalZenith использует передовую технологию термомеханической контролируемой переработки (TMCP), сочетая контролируемую прокатку в области рекристаллизации аустенита и не рекристаллизованной области, за которой следует ускоренное охлаждение. Этот процесс оптимизирует превращение аустенита в феррит, достигая мелких размеров зерен (ASTM 10-12) и однородных механических свойств. Наши установки непрерывного литья и горячей прокатки обеспечивают постоянный химический состав и однородность микроструктуры.

Варианты термообработки

Стандартное состояние поставки - нормализованное или TMCP. Дополнительные термообработки включают снятие напряжений при 580-650°C для улучшения размерной стабильности, а также закалку и отпуск для повышения прочностных свойств. Термообработка после сварки (PWHT) при 580-620°C может быть применена для снятия напряжений в сварных конструкциях.

Стандарты качества и испытания

Производство EN L485 компанией MetalZenith соответствует строгим протоколам контроля качества, включая 100% ультразвуковое тестирование на внутреннюю прочность, механические испытания по EN 10002-1 и испытания на ударную вязкость по Шарпи с заданными температурами. Химический анализ выполняется с использованием оптической эмиссионной спектроскопии с точностью ±0.005%. Все продукты поставляются с сертификатами испытаний EN 10204 типа 3.1 и возможной проверкой третьей стороной.

Учет сварки

EN L485 обладает отличной свариваемостью с низким эквивалентом углерода и контролируемым содержанием серы. Рекомендуемые процессы сварки включают SMAW, GMAW, SAW и FCAW. Требования к температуре предварительного подогрева минимальны (обычно 50-100°C) в зависимости от толщины и условий окружающей среды. Термообработка после сварки может быть указана для критических приложений для оптимизации свойств HAZ.

🧪 Chemical Composition

| Элемент | Состав (%) |

|---|---|

| Углерод (C) | ≤ 0.18 |

| Марганец (Mn) | 1.40 - 1.65 |

| Кремний (Si) | 0.15 - 0.45 |

| Фосфор (P) | ≤ 0.025 |

| Сера (S) | ≤ 0.015 |

| Хром (Cr) | ≤ 0.30 |

| Никель (Ni) | ≤ 0.30 |

| Молибден (Mo) | ≤ 0.15 |

| Медь (Cu) | ≤ 0.35 |

| Ниобий (Nb) | 0.02 - 0.05 |

| Ванадий (V) | ≤ 0.06 |

| Титан (Ti) | ≤ 0.04 |

| Алюминий (Al) | ≥ 0.015 |

| Азот (N) | ≤ 0.012 |

⚙️ Mechanical Properties

| Свойство | Значение |

|---|---|

| Предел текучести (Rp0.2) | 485 - 635 МПа |

| Предел прочности (Rm) | 570 - 760 МПа |

| Удлинение (A) | ≥ 18% |

| Соотношение предела текучести к пределу прочности | ≤ 0.93 |

| Энергия удара по Шарпи с V-образным вырезом (0°C) | ≥ 40 Дж |

| Энергия удара по Шарпи с V-образным вырезом (-20°C) | ≥ 27 Дж |

| Энергия удара по Шарпи с V-образным вырезом (-40°C) | ≥ 20 Дж |

| Твердость (HV10) | 200 - 280 |

| Модуль Юнга | 210 ГПа |

| Коэффициент Пуассона | 0.30 |

| Предел усталости (107 циклов) | 240 МПа |

| Критерий прочности (KIC) | 150 - 200 МПа·m1/2 |

🔬 Physical Properties

| Свойство | Значение |

|---|---|

| Плотность | 7.85 g/cm³ |

| Температура плавления | 1510 - 1540°C |

| Теплопроводность (20°C) | 54 W/m·K |

| Коэффициент теплового расширения (20-100°C) | 12×10-6/K |

| Удельная теплоемкость | 500 J/kg·K |

| Электрическое сопротивление (20°C) | 0.16 µΩ·m |

| Магнитная проницаемость | Ферромагнитный |

| Температура Кюри | 770°C |

| Тепловая диффузия | 13.7 mm²/s |

| Коэффициент линейного расширения (0-100°C) | 11.5×10-6/K |

| Эмиссия (окисленная поверхность) | 0.85 |

📏 Product Specifications

| Спецификация | Детали |

|---|---|

| Доступные формы | Пластины, Листы, Трубы, Трубки, Бруски, Катушки |

| Диапазон толщины пластин | 6 - 100 мм |

| Диапазон толщины листов | 2 - 6 мм |

| Диапазон диаметра труб | 168.3 - 1422 мм |

| Толщина стенки трубы | 6 - 40 мм |

| Стандартные ширины | 1500, 2000, 2500, 3000 мм |

| Стандартные длины | 6000, 9000, 12000 мм |

| Обработка поверхности | Горячекатаный, Нормализованный, Пескоструйный |

| Допуск по размерам | ±0.5% (толщина), ±5мм (ширина/длина) |

| Применимые стандарты | EN 10208-2, API 5L, ISO 3183, ASTM A333 |

| Условия поставки | Нормализованный, TMCP, Закаленный и Отпущенный |

| Состояние кромки | Мельничная кромка, Резаная кромка, Плазменная резка |

Давайте создадим успех для вашего проекта

Профессиональная команда, премиум-продукты, полный сервис - успех вашего проекта является нашей миссией

Our Advantages in Processing EN L485

Передовая технология TMCP

MetalZenith использует передовую термомеханическую контролируемую обработку (TMCP) с точным контролем температуры и ускоренными системами охлаждения, обеспечивая оптимальное уточнение микроструктуры и превосходные механические свойства в производстве стали EN L485.

Комплексный контроль качества

Наши современные испытательные лаборатории включают автоматизированный ультразвуковой контроль, испытания на ударный изгиб по Шарпи с V-образным вырезом при -40°C и системы химического анализа в реальном времени, что гарантирует стабильное качество и соответствие международным стандартам трубопроводов.

Пользовательские возможности обработки

MetalZenith предлагает обширные возможности настройки, включая специализированные термические обработки, точные размерные допуски и индивидуальные механические свойства для удовлетворения конкретных требований проекта и условий эксплуатации.

ВАШ НАДЕЖНЫЙ СТАЛЬ

ПАРТНЕР ПО ПРОИЗВОДСТВУ

Быстрый запрос

Отрасли, которые мы обслуживаем

Профессиональные стальные решения для основных отраслей

Квалификации и сертификаты