20 лет опыта | 1000+ партнеров по брендам | Полная настройка

У нас 20 лет опыта в отрасли, мы сотрудничаем с более чем 1,000 брендами и поддерживаем любые потребности в настройке.

Technical Specifications

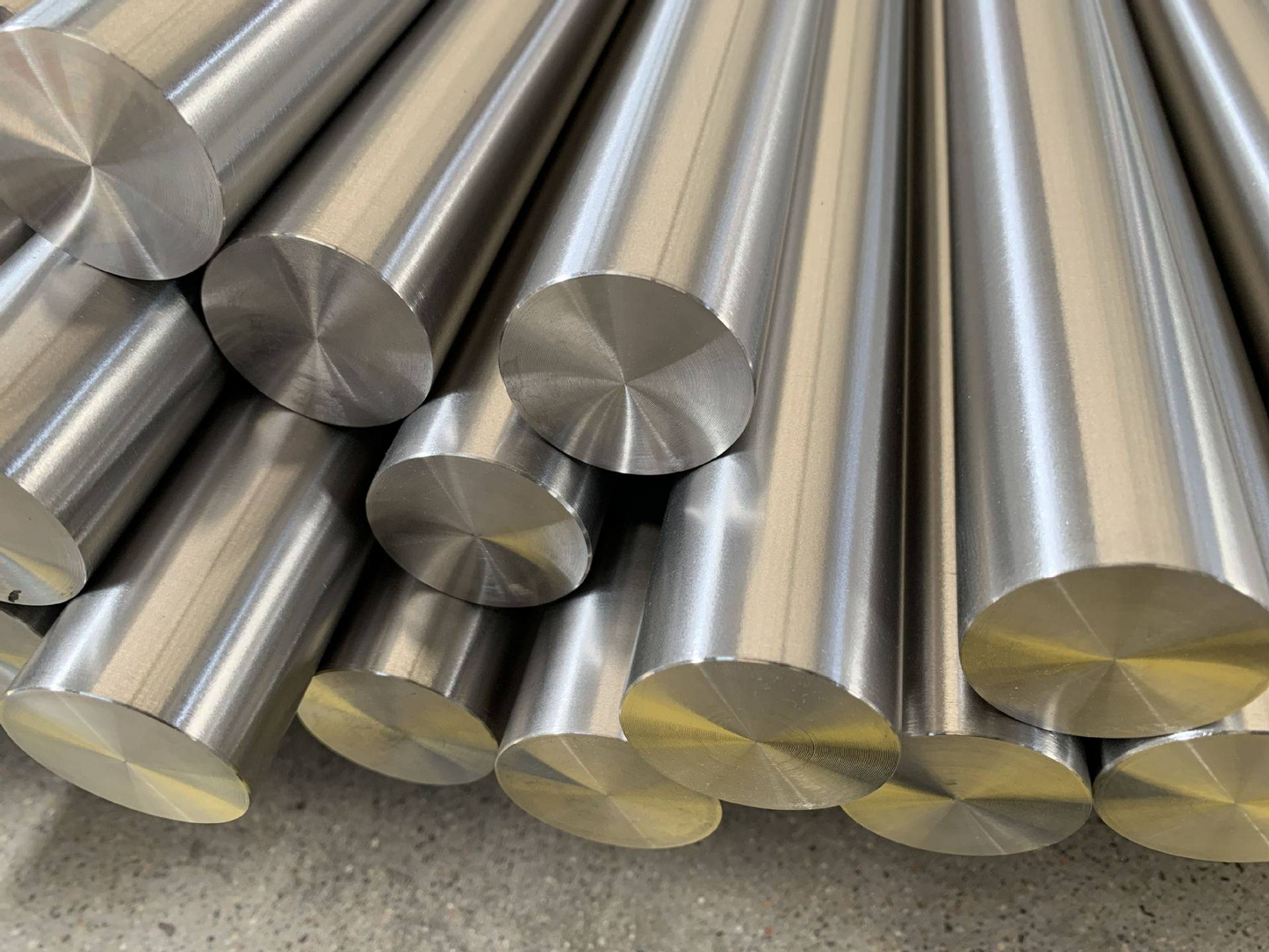

Product Overview

Металлургические характеристики

DILLIDUR 500V - это низколегированная, высокопрочная закаленная и отпущенная сталь с мелкозернистой мартенситной микроструктурой. Тщательно сбалансированный химический состав с контролируемым содержанием углерода и стратегическими легирующими элементами (Cr, Ni, Mo, B) обеспечивает оптимальную закаливаемость и прочность. Добавление бора улучшает закаливаемость, сохраняя характеристики свариваемости.

Процесс термообработки

Производственный процесс MetalZenith включает контролируемую прокатку при температурах от 1100 до 1200°C, за которой следует ускоренное охлаждение (закалка) с 900 до 950°C для достижения мартенситной структуры. Последующее отпускание при 200-300°C оптимизирует баланс между твердостью и прочностью. Весь процесс контролируется с использованием современных пирометров и компьютеризированных систем управления.

Контроль качества производства

Каждая производственная партия проходит комплексное тестирование, включая спектроскопический химический анализ, испытания на растяжение, испытания на ударную вязкость по Шарпи при различных температурах и измерение твердости по Бринеллю в нескольких местах. Ультразвуковое тестирование обеспечивает внутреннюю целостность, в то время как измерение размеров проверяет геометрические допуски. Все испытания проводятся в наших лабораториях, аккредитованных NADCAP.

Руководство по сварке и обработке

DILLIDUR 500V демонстрирует хорошую свариваемость при соблюдении правильных процедур. Рекомендуется предварительный подогрев до 100-150°C для толщин более 20 мм. Следует использовать низкогидрогеновые электроды (E7018 или эквивалент) с температурой между проходами, не превышающей 250°C. После сварки может потребоваться снятие напряжений для критических приложений.

Стандарты качества и сертификаты

MetalZenith поддерживает сертификаты ISO 9001:2015, ISO 14001:2015 и OHSAS 18001. Наши производственные мощности одобрены крупнейшими классификационными обществами, включая Lloyd's Register, DNV GL и ABS. Все продукты поставляются с сертификатами испытаний EN 10204-3.1 и полной документацией по отслеживаемости материалов.

🧪 Chemical Composition

| Элемент | Содержание (%) |

|---|---|

| Углерод (C) | ≤ 0.26 |

| Марганец (Mn) | 1.60 |

| Кремний (Si) | 0.70 |

| Фосфор (P) | ≤ 0.025 |

| Сера (S) | ≤ 0.010 |

| Хром (Cr) | 1.40 |

| Никель (Ni) | 1.00 |

| Молибден (Mo) | 0.60 |

| Бор (B) | 0.005 |

| Алюминий (Al) | ≥ 0.015 |

⚙️ Mechanical Properties

| Свойство | Значение |

|---|---|

| Твердость (HBW) | 500 ± 30 |

| Устойчивость к растяжению (Rm) | 1550-1750 MPa |

| Предельная прочность (Rp0.2) | ≥ 1300 MPa |

| Удлинение (A5) | ≥ 8% |

| Энергия удара (KV) при -40°C | ≥ 30 J |

| Энергия удара (KV) при -60°C | ≥ 20 J |

| Модуль Юнга | 210 GPa |

| Предельная усталостная прочность | 550 MPa |

| Коэффициент Пуассона | 0.30 |

🔬 Physical Properties

| Свойство | Значение |

|---|---|

| Плотность | 7.85 g/cm³ |

| Температура плавления | 1450-1520°C |

| Теплопроводность (20°C) | 42 W/m·K |

| Коэффициент теплового расширения (20-100°C) | 12×10-6/K |

| Удельная теплоемкость | 460 J/kg·K |

| Электрическое сопротивление (20°C) | 0.20 µΩ·m |

| Магнитная проницаемость | Ферромагнитный |

| Температура Кюри | 770°C |

📏 Product Specifications

| Спецификация | Детали |

|---|---|

| Доступные формы | Пластины, Листы, Изделия по размеру |

| Диапазон толщины | 4-80 мм |

| Диапазон ширины | 1000-3200 мм |

| Диапазон длины | 2000-12000 мм |

| Обработка поверхности | Горячекатаный, Пескоструйный, Кислотный |

| Состояние кромки | Мельничная кромка, Плазменная резка, Огонь резка |

| Допуск по толщине | ± 0.3 мм (t ≤ 20мм), ± 0.5 мм (t > 20мм) |

| Допуск по ширине | +0/-5 мм |

| Допуск по длине | +10/-0 мм |

| Соответствие стандартам | EN 10204-3.1, ASTM A514, JIS G3128 |

Давайте создадим успех для вашего проекта

Профессиональная команда, премиум-продукты, полный сервис - успех вашего проекта является нашей миссией

Our Advantages in Processing DILLIDUR 500V

Современные технологии закалки и отпуска

MetalZenith использует современные системы закалки и отпуска с компьютерным контролем температуры и технологией равномерного охлаждения, обеспечивая равномерное распределение твердости и оптимальную микроструктуру по всей толщине пластины для превосходной износостойкости.

Комплексная система контроля качества

Наша интегрированная система управления качеством включает в себя мониторинг химического состава в реальном времени, автоматизированное механическое тестирование, ультразвуковую инспекцию и проверку размеров. Каждая плита проходит строгие испытания с полной прослеживаемостью и сертификатом испытаний на заводе для гарантии стабильного качества.

Пользовательская обработка и глобальная цепочка поставок

MetalZenith предлагает обширные возможности настройки, включая точную резку, механическую обработку, формование и услуги по обработке поверхности. Наша глобальная сеть распределения обеспечивает надежную доставку по всему миру с гибкими логистическими решениями и технической поддержкой для конкретных требований применения.

ВАШ НАДЕЖНЫЙ СТАЛЬ

ПАРТНЕР ПО ПРОИЗВОДСТВУ

Быстрый запрос

Отрасли, которые мы обслуживаем

Профессиональные стальные решения для основных отраслей

Квалификации и сертификаты