20年の経験 | 1000以上のブランドパートナー | 完全なカスタマイズ

私たちは20年の業界経験があり、1,000以上のブランドと提携し、あらゆるカスタマイズニーズをサポートしています。

Technical Specifications

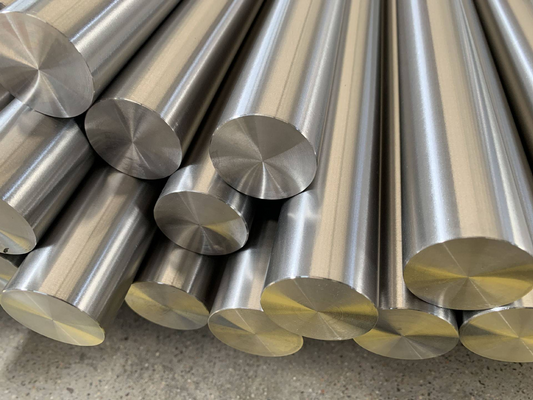

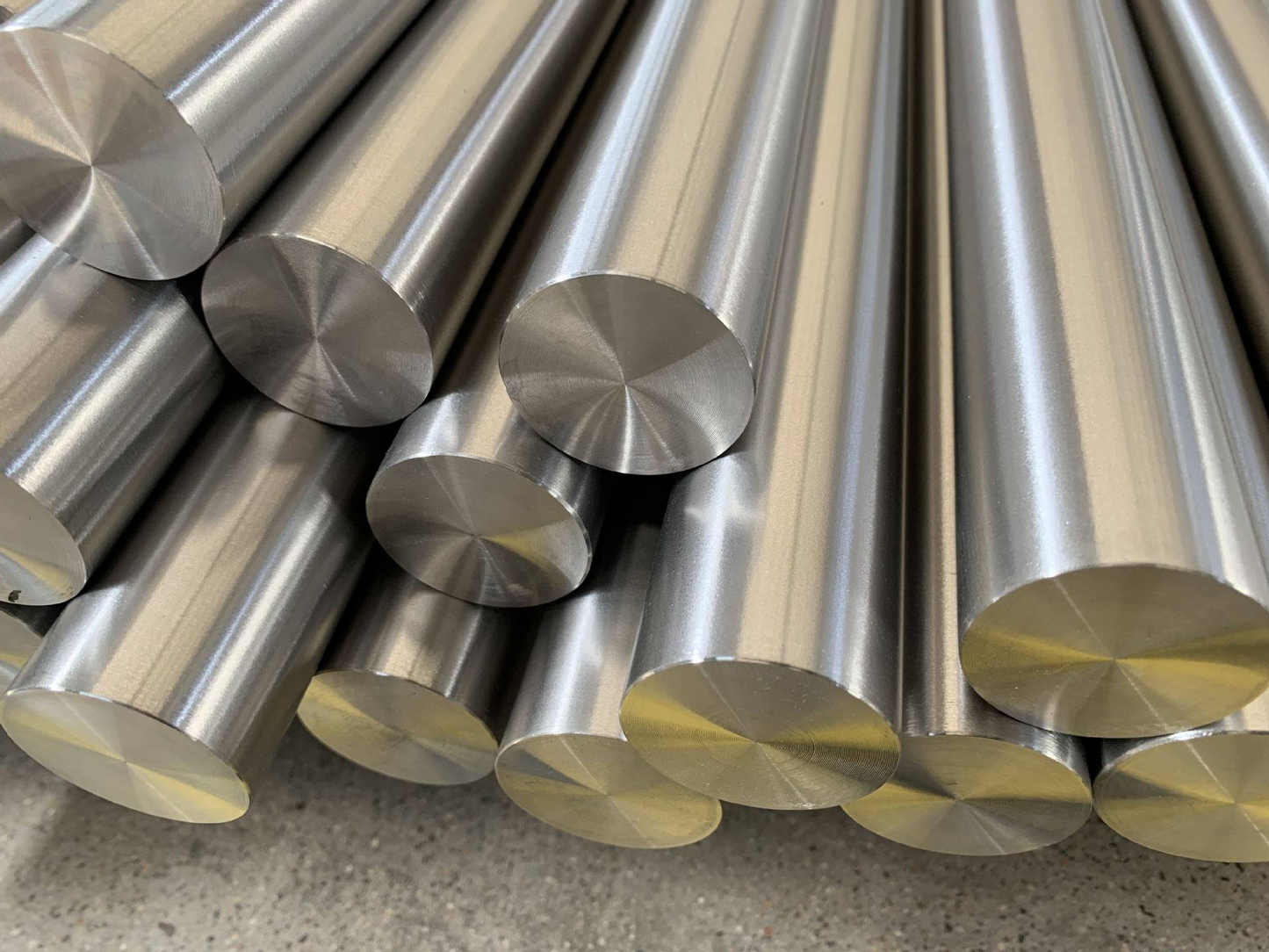

Product Overview

冶金特性

EN31鋼は、硬化後にマルテンサイト微細構造を示し、均一に分布したクロムカーバイドが優れた耐摩耗性と寸法安定性を提供します。高炭素含有量により深い硬化能力が可能で、クロムの添加は硬化性と耐腐食性を向上させます。MetalZenithの制御されたカーバイド形態は、構造用途における硬さと靭性の最適なバランスを確保します。

熱処理プロセス

MetalZenithは、加工性を向上させるために750-780°Cでの球状化アニーリングを含む正確な熱処理サイクルを採用し、その後820-860°Cでの硬化を行い、油または塩浴での制御された急冷を行います。150-200°Cでの焼戻しにより、最適な硬度保持を達成し、内部応力を緩和します。私たちのコンピュータ制御の炉は、プロセス全体で均一な加熱と正確な温度制御を保証します。

製造の卓越性

私たちの高度な製造プロセスは、水素含有量と不純物形成を最小限に抑えるために真空脱ガスを取り入れています。制御された鍛造および圧延操作は、結晶の流れを最適化し、内部欠陥を排除します。MetalZenithの品質システムには、重要な用途のための構造的完全性を保証するために100%の超音波検査と磁気粒子検査が含まれています。

専門的な品質テスト

EN31鋼は、耐久限界を評価するための回転ビーム疲労試験、熱サイクル下での寸法安定性分析、専門的なベアリング寿命試験を含む包括的なテストを受けます。私たちの研究所では、一貫した性能を確保するために、徹底的な硬化性研究、残留応力測定、微細構造分析を行います。

エンジニアリング用途

機械製造用途において、EN31は高負荷ベアリングシステムや精密機械部品において優れた耐摩耗性を提供します。車両製造においては、その優れた疲労強度により、駆動系部品やサスペンション要素に最適です。この鋼の寸法安定性と硬度保持は、長寿命と最小限のメンテナンスを必要とする一般的なエンジニアリング用途において信頼性のある性能を保証します。

🧪 Chemical Composition

| 元素 | 組成 (%) |

|---|---|

| 炭素 (C) | 0.95 - 1.10 |

| クロム (Cr) | 1.30 - 1.60 |

| マンガン (Mn) | 0.25 - 0.45 |

| シリコン (Si) | 0.15 - 0.35 |

| リン (P) | ≤ 0.025 |

| 硫黄 (S) | ≤ 0.025 |

| ニッケル (Ni) | ≤ 0.30 |

| 銅 (Cu) | ≤ 0.25 |

⚙️ Mechanical Properties

| プロパティ | 値 |

|---|---|

| 降伏強度 (MPa) | ≥ 1900 |

| 引張強度 (MPa) | 2100 - 2400 |

| 伸び (%) | ≥ 8 |

| 20°Cでの衝撃エネルギー (J) | ≥ 15 |

| 硬度 (HRC) | 60 - 67 |

| 疲労強度 (MPa) | ≥ 900 |

🔬 Physical Properties

| プロパティ | 値 |

|---|---|

| 密度 (g/cm3) | 7.81 |

| 融点 (°C) | 1420 - 1460 |

| 熱伝導率 (W/m·K) | 42.7 |

| 熱膨張 (×10??/K) | 12.3 |

| 弾性係数 (GPa) | 210 |

| ポアソン比 | 0.27 - 0.30 |

📏 Product Specifications

| 仕様 | 詳細 |

|---|---|

| 利用可能な形状 | バー、ロッド、チューブ、鍛造品、精密研削材 |

| 直径範囲 | 10 - 300mm |

| 長さ範囲 | 1000 - 6000mm |

| 表面仕上げ | 熱間圧延、冷間引抜、研削、研磨 |

| 規格適合 | ASTM A295, ISO 683-17, EN 10084, JIS G4805 |

| 熱処理条件 | 焼鈍、硬化および焼戻し、球状化 |

| 公差クラス | h9, h11 (冷間引抜), ±0.5mm (熱間圧延) |

あなたのプロジェクトの成功を共に創りましょう

プロフェッショナルチーム、プレミアム製品、完全なサービス - あなたのプロジェクトの成功は私たちの使命です

Our Advantages in Processing EN31鋼(52100)

高度な真空溶融技術

MetalZenithは、真空誘導溶解および電気スラグ再溶解プロセスを利用して、最小限の不純物を含む超クリーンな鋼を実現します。私たちの制御された雰囲気処理は、最適なカーバイド分布と疲労寿命の向上を保証し、卓越した信頼性を必要とする高性能構造用途にとって重要です。

包括的なパフォーマンステスト

私たちのEN31鋼は、シャルピー衝撃試験、回転ビーム疲労分析、特別なベアリング寿命評価を含む広範な試験を受けます。私たちは、要求される構造環境での最適な性能を確保するために、硬化性、寸法安定性、および残留応力パターンの徹底的な評価を行います。

精密熱処理サービス

MetalZenithは、コンピュータ制御の炉を使用した、通過硬化、表面硬化、精密焼戻しを含むカスタマイズされた熱処理ソリューションを提供します。私たちの冶金の専門知識は、特定の構造用途に対する最適な微細構造の発展と機械的特性の最適化を保証します。

あなたの信頼できる 鋼

製造パートナー

クイックお問い合わせ

私たちが提供する業界

主要産業向けのプロフェッショナルな鋼ソリューション

資格と認証