20 Tahun Pengalaman | 1000+ Mitra Merek | Kustomisasi Penuh

Kami memiliki 20 tahun pengalaman industri, telah bermitra dengan lebih dari 1.000 merek, dan mendukung kebutuhan kustomisasi apa pun.

Technical Specifications

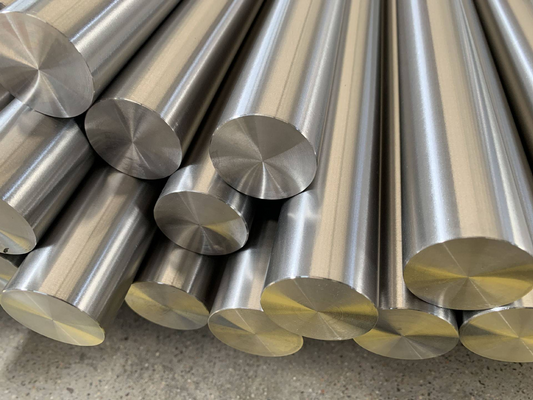

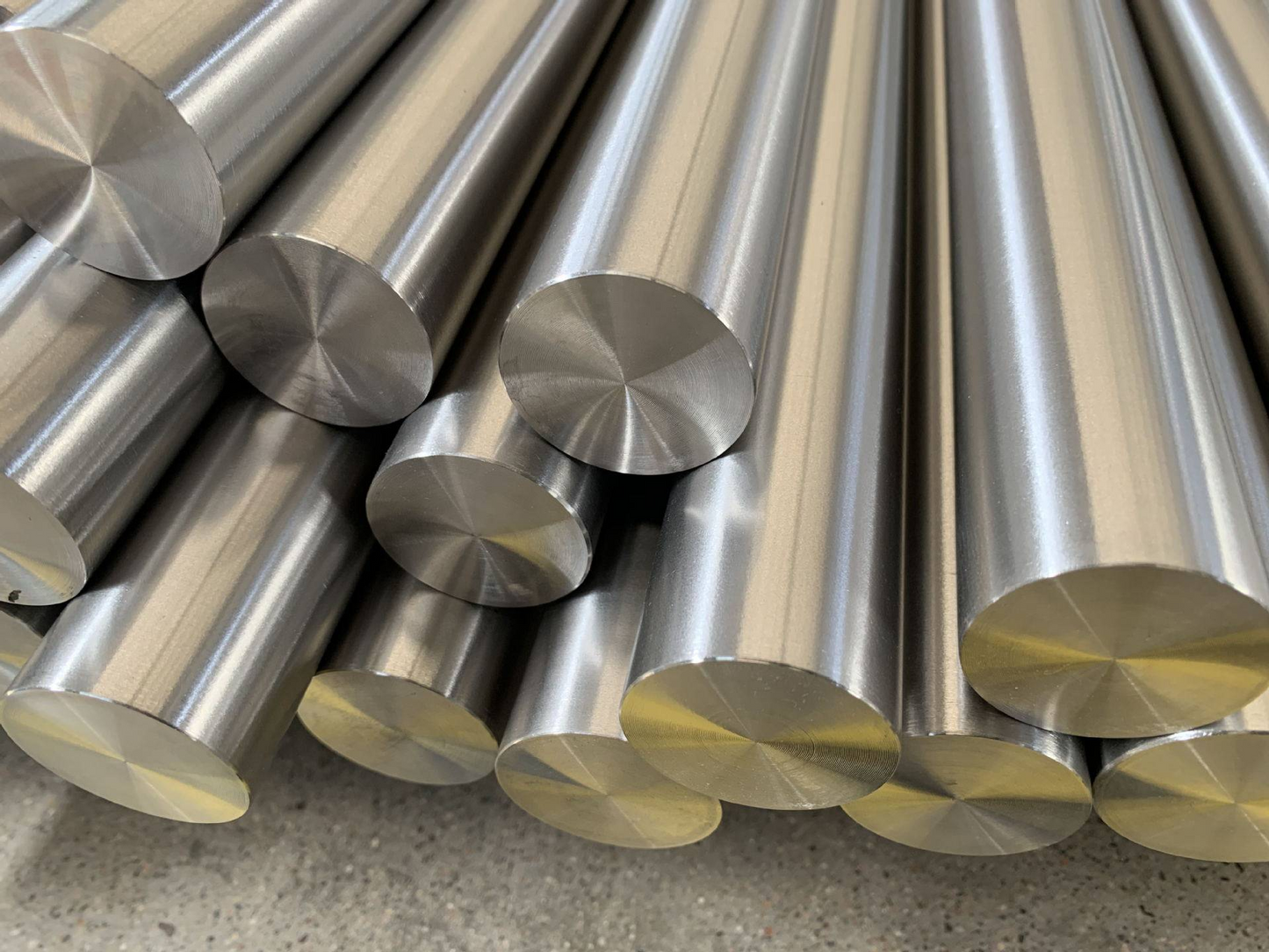

Product Overview

Karakteristik Metalurgi

EN 100CrMo7 adalah baja bantalan yang dapat dikeraskan secara menyeluruh dengan kemampuan pengerasan yang luar biasa karena kandungan kromium dan molibdenumnya. Kandungan karbon yang tinggi (0,95-1,05%) memberikan kekerasan yang diperlukan untuk aplikasi bantalan, sementara kromium (1,35-1,65%) meningkatkan ketahanan aus dan kemampuan pengerasan. Molibdenum (0,15-0,25%) meningkatkan ketangguhan dan mengurangi kerapuhan temper, menjadikan baja ini ideal untuk aplikasi bantalan dengan stres tinggi.

Proses Perlakuan Panas

Proses perlakuan panas proprietary MetalZenith dimulai dengan annealing spheroidizing pada 750-780°C untuk mengoptimalkan kemampuan mesin. Pengerasan dilakukan pada 820-860°C diikuti dengan pendinginan minyak untuk mencapai struktur martensitik. Tempering pada 150-200°C memberikan keseimbangan optimal antara kekerasan (60-64 HRC) dan ketangguhan. Laju pendinginan yang terkontrol dan manajemen atmosfer memastikan distorsi minimal dan mikrostruktur yang optimal.

Proses Manufaktur

Produksi dimulai dengan peleburan furnace busur listrik diikuti dengan metalurgi ladle untuk kontrol kimia yang tepat. Penghilangan vakum menghilangkan hidrogen dan mengurangi kandungan inklusi. Penuangan kontinu atau penuangan ingot diikuti dengan penggulungan panas atau penempaan untuk mencapai dimensi yang diinginkan. Proses pendinginan dan perlakuan panas yang terkontrol oleh MetalZenith memastikan sifat yang konsisten di seluruh penampang material.

Standar Kualitas & Pengujian

Semua produk EN 100CrMo7 menjalani pengujian komprehensif termasuk analisis kimia, verifikasi sifat mekanik, inspeksi ultrasonik, dan penilaian kebersihan sesuai ASTM E45. Pengujian kelelahan memvalidasi kinerja umur bantalan. MetalZenith mempertahankan jejak penuh dari bahan baku hingga inspeksi akhir, dengan sertifikat kepatuhan yang disediakan untuk semua pengiriman. Sistem manajemen kualitas kami memastikan kinerja yang konsisten memenuhi standar industri bantalan internasional.

🧪 Chemical Composition

| Elemen | Komposisi (%) |

|---|---|

| Karbon (C) | 0.95 - 1.05 |

| Silikon (Si) | 0.15 - 0.35 |

| Mangan (Mn) | 0.25 - 0.45 |

| Fosfor (P) | ≤ 0.025 |

| Belerang (S) | ≤ 0.015 |

| Krom (Cr) | 1.35 - 1.65 |

| Molybdenum (Mo) | 0.15 - 0.25 |

| Nikel (Ni) | ≤ 0.30 |

| Tembaga (Cu) | ≤ 0.25 |

| Aluminium (Al) | ≤ 0.050 |

⚙️ Mechanical Properties

| Properti | Nilai |

|---|---|

| Kekuatan Tarik (Ditempa) | 750 - 950 MPa |

| Kekuatan Luluh (Ditempa) | ≥ 450 MPa |

| Panjang Regangan (Ditempa) | ≥ 10% |

| Pengurangan Luas (Ditempa) | ≥ 35% |

| Kekerasan (Ditempa) | ≤ 255 HB |

| Kekerasan (Dikeraskan & Ditempa) | 60 - 64 HRC |

| Energi Impak (Ditempa, 20°C) | ≥ 25 J |

| Batas Kelelahan (Patah Putar) | 450 - 550 MPa |

| Modulus Young | 210 GPa |

| Rasio Poisson | 0.27 - 0.30 |

🔬 Physical Properties

| Properti | Nilai |

|---|---|

| Kepadatan | 7.85 g/cm³ |

| Titik Leleh | 1420 - 1460°C |

| Konduktivitas Termal (20°C) | 42 W/m·K |

| Koefisien Ekspansi Termal (20-100°C) | 11.5×10-6/K |

| Koefisien Ekspansi Termal (20-200°C) | 12.1×10-6/K |

| Kapasitas Panas Spesifik | 460 J/kg·K |

| Resistivitas Listrik (20°C) | 0.25 µΩ·m |

| Permeabilitas Magnetik | Ferromagnetik |

| Suhu Curie | ~760°C |

| Difusivitas Termal | 11.6 mm²/s |

📏 Product Specifications

| Spesifikasi | Detail |

|---|---|

| Bentuk yang Tersedia | Batang bulat, batang persegi, batang datar, cincin tempa, tabung, kawat |

| Diameter Batang Bulat | 10 - 500 mm |

| Ukuran Batang Persegi | 10×10 - 200×200 mm |

| Dimensi Batang Datar | Ketebalan: 5-100 mm, Lebar: 20-300 mm |

| Diameter Kawat | 0.5 - 20 mm |

| Panjang | Hingga 12 meter (standar), panjang kustom tersedia |

| Finishing Permukaan | Hitam, dibubut, digiling, dipoles |

| Toleransi Dimensi | h9 hingga h11 (standar), h6 hingga h8 (presisi) |

| Kepatuhan Standar | EN 10132-4, ASTM A295, JIS G4805, DIN 17230 |

| Kondisi Perlakuan Panas | Diannealing, spheroidized, hardened & tempered |

Mari Kita Ciptakan Kesuksesan untuk Proyek Anda

Tim Profesional, Produk Premium, Layanan Lengkap - Keberhasilan Proyek Anda adalah Misi Kami

Our Advantages in Processing 100CrMo7

Teknologi Peleburan Vakum Lanjutan

MetalZenith menggunakan proses peleburan induksi vakum (VIM) dan peleburan busur vakum (VAR) yang canggih untuk memproduksi EN 100CrMo7 dengan kebersihan dan homogenitas yang luar biasa. Peleburan atmosfer terkendali kami menghilangkan inklusi dan memastikan distribusi karbida yang optimal untuk kinerja bantalan yang superior.

Kontrol Perlakuan Panas Presisi

Fasilitas perlakuan panas yang dikendalikan komputer kami dilengkapi dengan tungku multi-zona dengan pemantauan suhu yang tepat dan kontrol atmosfer. Proses pendinginan dan penempaan milik MetalZenith mencapai profil kekerasan yang konsisten dan mikrostruktur optimal untuk umur lelah maksimum dan stabilitas dimensi.

Pengujian Komprehensif & Kustomisasi

MetalZenith menyediakan karakterisasi material lengkap termasuk penilaian kebersihan, analisis ukuran butir, dan pengujian kelelahan. Kami menawarkan modifikasi kimia kustom, perlakuan panas khusus, dan layanan pemesinan presisi untuk memenuhi persyaratan aplikasi tertentu dengan dokumentasi jejak penuh.

ANDA YANG DIPERCAYA BAJA

MITRA MANUFAKTUR

Pertanyaan Cepat

Industri yang Kami Layani

Solusi baja profesional di berbagai industri

Kualifikasi & Sertifikasi