20 Years Experience | 1000+ Brand Partners | Full Customization

We have 20 years of industry experience, have partnered with over 1,000 brands, and support any customization needs.

Technical Specifications

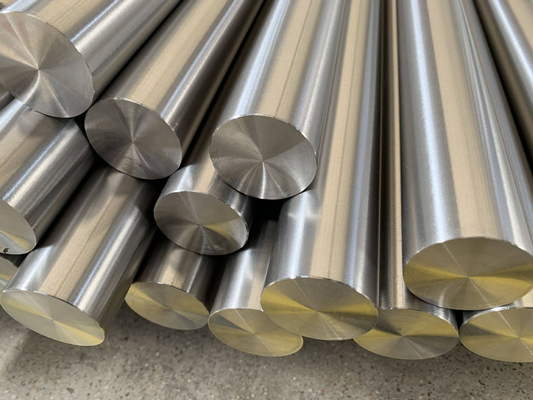

Product Overview

Metallurgical Characteristics

UNS N04400 (Monel 400) is a single-phase, solid-solution nickel-copper alloy with exceptional corrosion resistance in marine environments and reducing conditions. The alloy's face-centered cubic crystal structure provides excellent ductility and formability while maintaining strength across a wide temperature range.

Manufacturing Process

MetalZenith employs vacuum induction melting (VIM) followed by electroslag remelting (ESR) to achieve superior chemical homogeneity and cleanliness. The ingots undergo controlled hot working at 1000-1150°C, followed by intermediate annealing and cold working to achieve desired mechanical properties. Final annealing is performed at 870-980°C in controlled atmosphere furnaces.

Heat Treatment Procedures

Solution annealing is conducted at 870-980°C followed by rapid cooling to prevent precipitation of secondary phases. Cold working can increase strength significantly, with work hardening rates of 300-400 MPa per 10% reduction. Stress relief annealing at 540-650°C may be applied to reduce residual stresses without significant softening.

Quality Standards & Certifications

All UNS N04400 products manufactured by MetalZenith comply with ASTM B127, ASME SB-127, AMS 4674/4675, and EN 2.4360 specifications. Our quality management system is certified to ISO 9001:2015, AS9100D for aerospace applications, and NORSOK M-650 for offshore applications. Comprehensive testing includes chemical analysis by ICP-OES, mechanical testing per ASTM standards, ultrasonic testing, and corrosion testing in simulated service environments.

🧪 Chemical Composition

| Element | Composition (%) |

|---|---|

| Nickel (Ni) | 63.0 - 70.0 |

| Copper (Cu) | Remainder |

| Iron (Fe) | ≤ 2.50 |

| Manganese (Mn) | ≤ 2.00 |

| Carbon (C) | ≤ 0.30 |

| Silicon (Si) | ≤ 0.50 |

| Sulfur (S) | ≤ 0.024 |

⚙️ Mechanical Properties

| Property | Annealed Condition | Cold Worked |

|---|---|---|

| Tensile Strength | 550-750 MPa | 700-1100 MPa |

| Yield Strength (0.2% offset) | 240-350 MPa | 550-900 MPa |

| Elongation in 50mm | ≥ 35% | 15-25% |

| Hardness (Brinell) | 110-150 HB | 200-300 HB |

| Young's Modulus | 179 GPa | 179 GPa |

| Impact Energy (Charpy V-notch) | ≥ 200 J | 100-150 J |

| Fatigue Limit (10&sup7; cycles) | 240 MPa | 350 MPa |

🔬 Physical Properties

| Property | Value |

|---|---|

| Density | 8.83 g/cm³ |

| Melting Point | 1300-1350°C |

| Thermal Conductivity (20°C) | 21.8 W/m·K |

| Thermal Expansion Coefficient (20-100°C) | 13.9×10-6/K |

| Specific Heat Capacity | 427 J/kg·K |

| Electrical Resistivity (20°C) | 0.547 µΩ·m |

| Magnetic Permeability | Non-magnetic |

| Curie Temperature | Not applicable |

📏 Product Specifications

| Product Form | Available Sizes | Standards |

|---|---|---|

| Round Bars | 6mm - 300mm diameter | ASTM B127, AMS 4674 |

| Flat Bars | 10-100mm thick, up to 300mm wide | ASTM B127, ASME SB-127 |

| Sheets & Plates | 0.5-50mm thick, up to 2000mm wide | ASTM B127, EN 2.4360 |

| Seamless Tubes | 6-200mm OD, 1-20mm wall | ASTM B165, ASME SB-165 |

| Welded Tubes | 10-300mm OD, 1-15mm wall | ASTM B165, ASME SB-165 |

| Wire | 0.1-10mm diameter | ASTM B164, AMS 4675 |

| Surface Finish | Hot rolled, cold drawn, annealed, pickled | Ra 0.8-6.3 µm |

| Tolerance | Standard: ±0.1mm, Precision: ±0.05mm | ISO 2768, DIN 7168 |

Let Us Create Success for Your Project

Professional Team, Premium Products, Complete Service - Your Project Success is Our Mission

Our Advantages in Processing UNS N04400

Advanced Vacuum Melting Technology

MetalZenith employs state-of-the-art vacuum induction melting (VIM) and electroslag remelting (ESR) processes to produce UNS N04400 with superior chemical homogeneity, reduced inclusions, and enhanced mechanical properties for critical applications.

Comprehensive Quality Control Systems

Our integrated quality management system features real-time process monitoring, advanced spectroscopic analysis, mechanical testing laboratories, and non-destructive testing capabilities ensuring consistent product quality and full traceability.

Custom Processing & Global Supply

MetalZenith offers extensive customization capabilities including specialized heat treatments, precision machining, and custom dimensions. Our global distribution network ensures reliable delivery worldwide with comprehensive technical support.

YOUR TRUSTED STEEL

MANUFACTURING PARTNER

Quick Inquiry

Industries We Serve

Professional steel solutions across major industries

Qualifications & Certifications