20 Years Experience | 1000+ Brand Partners | Full Customization

We have 20 years of industry experience, have partnered with over 1,000 brands, and support any customization needs.

Technical Specifications

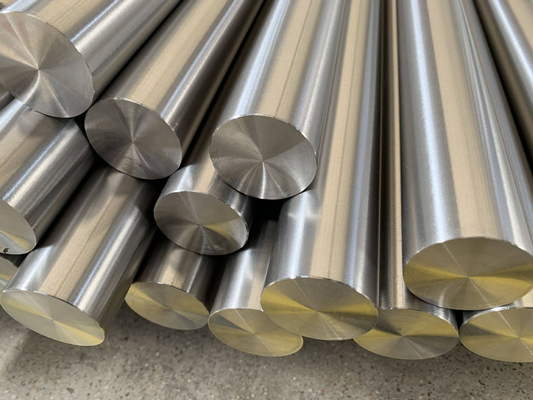

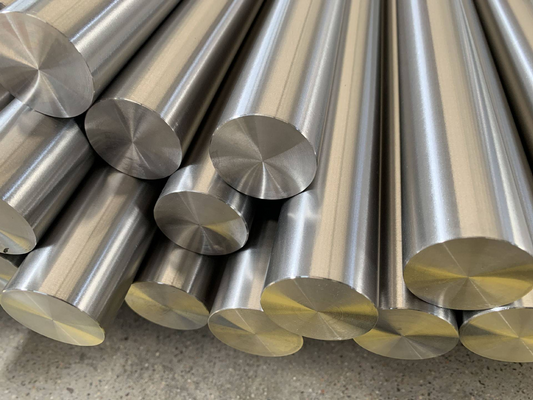

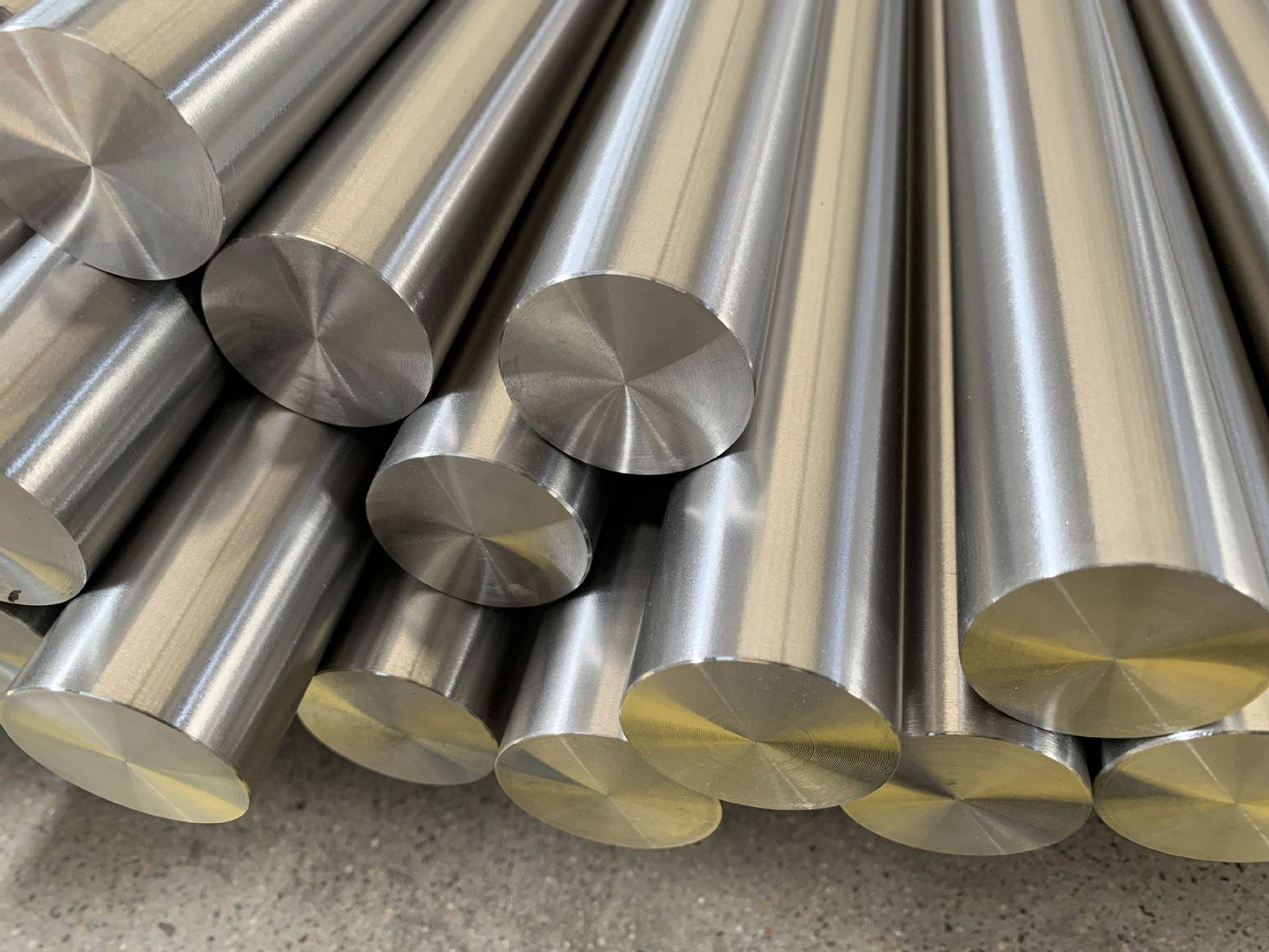

Product Overview

Metallurgical Characteristics

UNS N07040 (Nimonic 75) is a precipitation-hardened nickel-chromium superalloy strengthened by gamma-prime (Ni&sub3;Ti) precipitates. The alloy exhibits exceptional high-temperature strength retention, oxidation resistance, and thermal stability up to 850°C. The microstructure consists of an austenitic matrix with uniformly distributed coherent gamma-prime precipitates that provide superior creep resistance and thermal fatigue properties.

Heat Treatment Process

MetalZenith employs a precise two-stage heat treatment process: Solution annealing at 1080°C for 8 hours followed by air cooling, then precipitation hardening at 700°C for 16 hours with air cooling. This optimized thermal cycle ensures maximum precipitation of strengthening phases while maintaining excellent ductility and toughness. Our computer-controlled furnaces maintain temperature uniformity within ±5°C throughout the treatment cycle.

Manufacturing Process Excellence

MetalZenith utilizes advanced vacuum induction melting (VIM) followed by vacuum arc remelting (VAR) to achieve exceptional cleanliness and homogeneity. Our thermomechanical processing includes controlled hot working at 1000-1150°C with precise strain rates to optimize grain structure and mechanical properties. Cold working operations are performed with intermediate annealing cycles to prevent work hardening and maintain dimensional accuracy.

Quality Standards & Testing

Every UNS N07040 product undergoes comprehensive testing per ASTM B637 and AMS 5382 standards. Our quality protocol includes chemical analysis by optical emission spectroscopy, mechanical testing at room and elevated temperatures, microstructural examination, ultrasonic testing, and dimensional verification. All products are supplied with certified test reports and full traceability documentation meeting aerospace and nuclear industry requirements.

Corrosion Resistance & Environmental Performance

The high chromium content provides excellent oxidation resistance in air up to 950°C and superior resistance to sulfidation and carburization. The alloy demonstrates exceptional performance in reducing atmospheres and shows good resistance to stress corrosion cracking in chloride environments. MetalZenith conducts accelerated corrosion testing to validate long-term performance in specific operating environments.

🧪 Chemical Composition

| Element | Composition (%) |

|---|---|

| Nickel (Ni) | Balance (76.0 min) |

| Chromium (Cr) | 18.0 - 21.0 |

| Titanium (Ti) | 0.20 - 0.60 |

| Carbon (C) | 0.08 - 0.15 |

| Iron (Fe) | ≤ 5.0 |

| Manganese (Mn) | ≤ 1.0 |

| Silicon (Si) | ≤ 1.0 |

| Sulfur (S) | ≤ 0.015 |

| Phosphorus (P) | ≤ 0.030 |

| Copper (Cu) | ≤ 0.20 |

⚙️ Mechanical Properties

| Property | Value | Test Temperature |

|---|---|---|

| Tensile Strength | 850 - 1050 MPa | Room Temperature |

| Yield Strength (0.2% Offset) | ≥ 480 MPa | Room Temperature |

| Elongation | ≥ 20% | Room Temperature |

| Reduction of Area | ≥ 25% | Room Temperature |

| Hardness (HRC) | 28 - 35 | Room Temperature |

| Young's Modulus | 210 GPa | Room Temperature |

| Tensile Strength | 620 MPa | 700°C |

| Yield Strength | 380 MPa | 700°C |

| Impact Energy (Charpy V-notch) | ≥ 40 J | Room Temperature |

| Fatigue Strength (10&sup7; cycles) | 400 MPa | Room Temperature |

🔬 Physical Properties

| Property | Value | Temperature Range |

|---|---|---|

| Density | 8.19 g/cm³ | 20°C |

| Melting Point | 1390 - 1425°C | - |

| Thermal Conductivity | 11.2 W/m·K | 20°C |

| Thermal Conductivity | 18.5 W/m·K | 500°C |

| Specific Heat Capacity | 460 J/kg·K | 20°C |

| Thermal Expansion Coefficient | 12.8×10-6/K | 20-100°C |

| Thermal Expansion Coefficient | 15.2×10-6/K | 20-700°C |

| Electrical Resistivity | 1.18 µΩ·m | 20°C |

| Magnetic Permeability | Paramagnetic | Room Temperature |

| Curie Temperature | Not Applicable | - |

📏 Product Specifications

| Specification | Available Options |

|---|---|

| Product Forms | Round Bar, Flat Bar, Sheet, Plate, Strip, Wire, Tube, Pipe, Forging Stock |

| Round Bar Diameter | 6mm - 300mm (±0.1mm tolerance) |

| Sheet Thickness | 0.5mm - 6mm (±0.05mm tolerance) |

| Plate Thickness | 6mm - 100mm (±0.1mm tolerance) |

| Wire Diameter | 0.1mm - 10mm (±0.02mm tolerance) |

| Tube Outer Diameter | 6mm - 200mm (wall thickness 0.5-20mm) |

| International Standards | ASTM B637, AMS 5382, BS HR 6, DIN 17742, EN 2.4630 |

| Surface Finish | Hot Rolled, Cold Drawn, Bright Annealed, Pickled, Ground, Polished |

| Heat Treatment Condition | Solution Annealed, Precipitation Hardened, Stress Relieved |

| Length Options | Standard: 3m, 6m; Custom lengths available up to 12m |

| Packaging | Wooden Crates, Steel Bundles, Protective Wrapping, Export Packaging |

Let Us Create Success for Your Project

Professional Team, Premium Products, Complete Service - Your Project Success is Our Mission

Our Advantages in Processing UNS N07040

Advanced Vacuum Melting Technology

MetalZenith utilizes cutting-edge vacuum induction melting (VIM) and vacuum arc remelting (VAR) processes to produce ultra-clean UNS N07040 with minimal inclusions and superior metallurgical homogeneity, ensuring exceptional high-temperature performance and reliability.

Precision Heat Treatment Control

Our state-of-the-art heat treatment facilities feature computer-controlled atmosphere furnaces with precise temperature uniformity (±5°C) and atmosphere control, optimizing precipitation hardening for maximum strength and consistent mechanical properties throughout the material.

Complete Supply Chain Integration

MetalZenith offers comprehensive customization from raw material to finished components, including precision machining, surface treatments, and packaging. Our global logistics network ensures timely delivery with full traceability and certification documentation for aerospace and critical applications.

YOUR TRUSTED STEEL

MANUFACTURING PARTNER

Quick Inquiry

Industries We Serve

Professional steel solutions across major industries

Qualifications & Certifications