20 Jahre Erfahrung | 1000+ Markenpartner | Vollständige Anpassung

Wir haben 20 Jahre Branchenerfahrung, haben mit über 1.000 Marken zusammengearbeitet und unterstützen alle Anpassungsbedürfnisse.

Technical Specifications

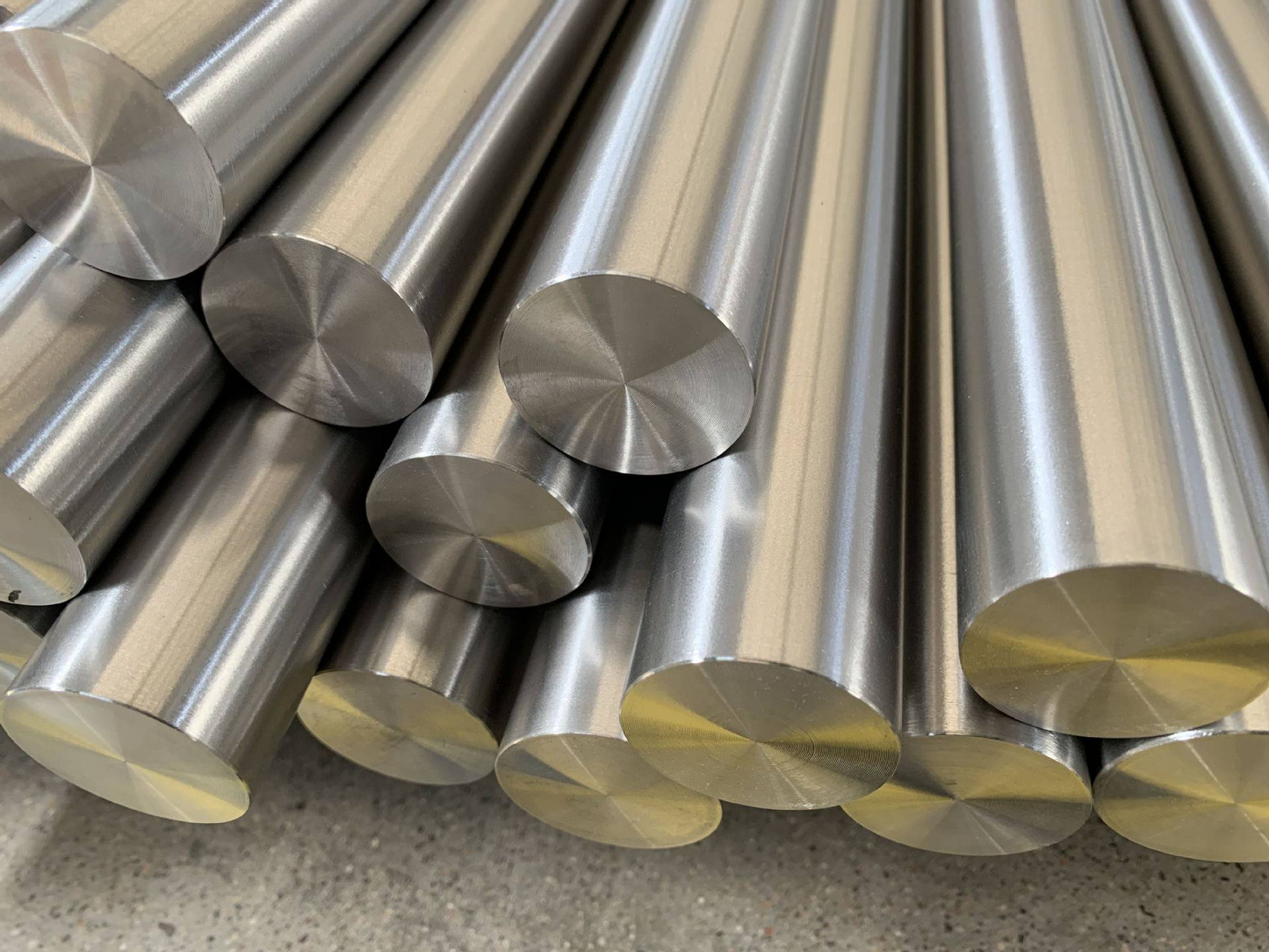

Product Overview

Metallurgische Eigenschaften

S7 ist ein schockbeständiger Werkzeugstahl aus Chrom-Wolfram-Molybdän, der für Anwendungen entwickelt wurde, die außergewöhnliche Zähigkeit und Schlagfestigkeit erfordern. Die einzigartige Zusammensetzung der Legierung schafft eine feinkörnige martensitische Struktur mit gut verteilten Karbiden, die hervorragende Stoßdämpfungseigenschaften bieten und gleichzeitig eine gute Verschleißfestigkeit aufrechterhalten.

Wärmebehandlungsprozess

Die optimierte Wärmebehandlung von MetalZenith umfasst das Vorheizen auf 650-700°C, gefolgt von Austenitisierung bei 940-980°C in schützender Atmosphäre. Das Abschrecken erfolgt in Öl oder Luft, abhängig von der Querschnittsgröße, gefolgt von Anlassen bei 150-650°C, um die gewünschten Härtegrade zu erreichen. Unsere kontrollierten Abkühlraten gewährleisten minimale Verzerrungen und eine optimale Mikrostruktur.

Herstellungsprozess

Die Produktion beginnt mit dem Schmelzen im Lichtbogenofen unter Verwendung von hochwertigen Rohmaterialien, gefolgt von der Pfannenverfeinerung und Vakuumentgasung. Der Stahl wird einer Elektroschlacke-Umschmelzung (ESR) unterzogen, um die Reinheit und Homogenität zu verbessern. Warmumformung und kontrollierte Abkühlung optimieren die Kornstruktur, während präzise Bearbeitung und Oberflächenbehandlungen die genauen Kundenspezifikationen erfüllen.

Qualitätsstandards

Alle S7-Stahlprodukte entsprechen internationalen Standards, einschließlich ASTM A681, DIN 1.2355 und JIS SKS3. Umfassende Tests umfassen chemische Analysen durch optische Emissionsspektroskopie, Überprüfung der mechanischen Eigenschaften, Ultraschallinspektion auf innere Festigkeit und dimensionale Überprüfung. Unser Qualitätsmanagementsystem ISO 9001:2015 gewährleistet konsistente Produktqualität und vollständige Rückverfolgbarkeit von Rohmaterialien bis zu fertigen Produkten.

🧪 Chemical Composition

| Element | Zusammensetzung (%) |

|---|---|

| Kohlenstoff (C) | 0.45 - 0.55 |

| Mangan (Mn) | 0.20 - 0.80 |

| Silizium (Si) | 0.20 - 1.00 |

| Phosphor (P) | ≤ 0.030 |

| Schwefel (S) | ≤ 0.030 |

| Chrom (Cr) | 3.00 - 3.50 |

| Molybdän (Mo) | 1.30 - 1.80 |

| Wolfram (W) | 1.30 - 1.80 |

| Nickel (Ni) | ≤ 0.30 |

| Kupfer (Cu) | ≤ 0.25 |

⚙️ Mechanical Properties

| Eigenschaft | Wert |

|---|---|

| Zugfestigkeit (geglüht) | 690 - 790 MPa |

| Streckgrenze (geglüht) | 415 - 485 MPa |

| Dehnung (geglüht) | 22 - 28% |

| Querschnittsreduktion (geglüht) | 45 - 55% |

| Härte (geglüht) | 197 - 229 HB |

| Härte (gehärtet & angelassen) | 54 - 58 HRC |

| Schlagenergie (Charpy V-Kerbe) | 40 - 60 J |

| Ermüdungsgrenze | 550 - 650 MPa |

| Elastizitätsmodul | 210 GPa |

| Poisson-Zahl | 0.27 - 0.30 |

🔬 Physical Properties

| Eigenschaft | Wert |

|---|---|

| Dichte | 7.80 g/cm³ |

| Schmelzpunkt | 1480 - 1520°C |

| Wärmeleitfähigkeit (20°C) | 28 W/m·K |

| Wärmeausdehnungskoeffizient (20-100°C) | 11.5×10-6/K |

| Wärmeausdehnungskoeffizient (20-200°C) | 12.2×10-6/K |

| Spezifische Wärmekapazität | 460 J/kg·K |

| Elektrische Widerstandsfähigkeit (20°C) | 0.65 µΩ·m |

| Magnetische Permeabilität | Ferromagnetisch |

| Curie-Temperatur | 760°C |

| Wärmediffusivität | 7.8×10-6 m²/s |

📏 Product Specifications

| Spezifikation | Details |

|---|---|

| Verfügbare Formen | Runde Stangen, Flachstangen, Platten, Blöcke, Schmiedeteile |

| Durchmesser der Rundstange | 6 - 500 mm |

| Dicke der Flachstange | 10 - 200 mm |

| Dicke der Platte | 20 - 300 mm |

| Standardlänge | 3000 - 6000 mm (maßgeschneiderte Längen verfügbar) |

| Oberflächenfinish | Warmgewalzt, geglüht, bearbeitet, geschliffen |

| Dimensionale Toleranz | ±0.1 mm (präzisionsbearbeitet) |

| Einhaltung von Standards | ASTM A681, DIN 1.2355, JIS SKS3 |

| Wärmebehandlungszustand | Geglüht, gehärtet & vergütet (optional) |

| Qualitätszertifizierung | Werksprüfzertifikat, chemische Analyse, mechanische Eigenschaften |

Lassen Sie uns Erfolg für Ihr Projekt schaffen

Professionelles Team, Premium-Produkte, Vollständiger Service - Ihr Projekterfolg ist unsere Mission

Our Advantages in Processing S7

Fortgeschrittene Vakuum-Schmelztechnologie

MetalZenith verwendet modernste Vakuum-Induktionsschmelzen (VIM) und Elektroschlacke-Umschmelzen (ESR), um S7-Stahl mit außergewöhnlicher Sauberkeit und chemischer Homogenität herzustellen. Unser kontrollierter Atmosphärenprozess beseitigt schädliche Einschlüsse und gewährleistet eine konsistente Kornstruktur für optimale Schlagfestigkeit und Zuverlässigkeit.

Präzise Wärmebehandlungssteuerung

Unsere proprietären Wärmebehandlungsprotokolle nutzen computergesteuerte Öfen mit präziser Temperaturüberwachung und Atmosphärenkontrolle. Dies gewährleistet eine optimale Karbidverteilung und ein ausgewogenes Matrixhärteverhältnis, was konsistente mechanische Eigenschaften liefert und die Schlagzähigkeitseigenschaften von S7-Stahl maximiert.

Umfassende Anpassungsdienste

MetalZenith bietet umfangreiche Anpassungsmöglichkeiten, einschließlich Präzisionsbearbeitung, spezialisierter Wärmebehandlungszyklen und maßgeschneiderter Abmessungen. Unser globales Lieferkettennetzwerk gewährleistet eine schnelle Lieferung weltweit, während unser technisches Support-Team fachkundige Beratung für anwendungsspezifische Anforderungen und Leistungsoptimierung bietet.

IHR VERTRAUENwürdiger STAHL

HERSTELLUNGSPARTNER

Schnellanfrage

Branchen, die wir bedienen

Professionelle Stahl-Lösungen in wichtigen Branchen

Qualifikationen & Zertifizierungen