20 Anos de Experiência | 1000+ Parceiros de Marca | Personalização Completa

Temos 20 anos de experiência na indústria, fizemos parceria com mais de 1.000 marcas e apoiamos quaisquer necessidades de personalização.

Technical Specifications

Product Overview

Características Metalúrgicas

EH40 é um aço estrutural normalizado de grão fino com uma microestrutura predominantemente ferrítica-perlítica. O processo de laminação controlada seguido pelo tratamento térmico de normalização a 900-950°C resulta em um tamanho de grão refinado (ASTM 8-10) e precipitação ótima de elementos microaleantes, proporcionando um excelente equilíbrio entre resistência e tenacidade.

Processo de Tratamento Térmico

A MetalZenith emprega normalização controlada a 920±20°C seguida de resfriamento ao ar para alcançar uma microestrutura e propriedades mecânicas uniformes. O revenimento opcional a 580-620°C pode ser aplicado para aumentar a tenacidade em aplicações críticas. Nossos fornos controlados por computador garantem uniformidade precisa de temperatura e taxas de aquecimento.

Processo de Fabricação

A produção começa com a fusão em forno de arco elétrico seguida de refino em panela e desgasificação a vácuo para alcançar um teor de enxofre ultra-baixo. A fundição contínua produz placas de alta qualidade que passam por laminação controlada com controle preciso de temperatura. O tratamento final de normalização garante propriedades mecânicas ótimas e alívio de tensões.

Normas de Qualidade & Testes

Todos os produtos EH40 passam por testes abrangentes, incluindo análise química, teste de tração, teste de impacto Charpy V-notch a -40°C e -60°C, medição de dureza e inspeção ultrassônica. A certificação de terceiros de sociedades de classificação importantes garante conformidade com os requisitos de construção offshore e normas internacionais.

Soldabilidade & Fabricação

EH40 apresenta excelente soldabilidade com equivalente de carbono (CEV) tipicamente ≤ 0.41%. O pré-aquecimento a 100-150°C é recomendado para seções espessas. O tratamento térmico pós-solda pode ser necessário para alívio de tensões em aplicações críticas. O aço é adequado para todos os processos de soldagem convencionais, incluindo SMAW, GMAW, SAW e FCAW.

🧪 Chemical Composition

| Elemento | Composição (%) |

|---|---|

| Carbono (C) | ≤ 0.18 |

| Manganês (Mn) | 0.90 - 1.60 |

| Silício (Si) | 0.10 - 0.50 |

| Fósforo (P) | ≤ 0.025 |

| Enxofre (S) | ≤ 0.015 |

| Cromo (Cr) | ≤ 0.20 |

| Níquel (Ni) | ≤ 0.40 |

| Molibdênio (Mo) | ≤ 0.08 |

| Cobre (Cu) | ≤ 0.35 |

| Alumínio (Al) | ≥ 0.015 |

| Nióbio (Nb) | ≤ 0.05 |

| Vanádio (V) | ≤ 0.10 |

| Titânio (Ti) | ≤ 0.02 |

⚙️ Mechanical Properties

| Propriedade | Valor |

|---|---|

| Limite de Escoamento (ReH) | 390 - 530 MPa |

| Limite de Resistência (Rm) | 510 - 660 MPa |

| Alongamento (A5) | ≥ 20% |

| Energia de Impacto (KV a -40°C) | ≥ 27 J |

| Energia de Impacto (KV a -60°C) | ≥ 20 J |

| Dureza Brinell (HB) | 150 - 220 |

| Módulo de Young | 210 GPa |

| Razão de Poisson | 0.30 |

| Limite de Fadiga (107 ciclos) | 180 - 220 MPa |

| Tenacidade à Fratura (K1C) | 120 - 150 MPa·m1/2 |

🔬 Physical Properties

| Propriedade | Valor |

|---|---|

| Densidade | 7.85 g/cm³ |

| Ponto de Fusão | 1510 - 1540°C |

| Condutividade Térmica (20°C) | 52 W/m·K |

| Coeficiente de Expansão Térmica (20-100°C) | 12.5×10-6/K |

| Capacidade Calorífica Específica | 460 J/kg·K |

| Resistividade Elétrica (20°C) | 0.15 µΩ·m |

| Permeabilidade Magnética | Ferromagnético |

| Temperatura de Curie | 770°C |

| Difusividade Térmica | 14.4 mm²/s |

| Emissividade (superfície oxidada) | 0.79 |

📏 Product Specifications

| Especificação | Detalhes |

|---|---|

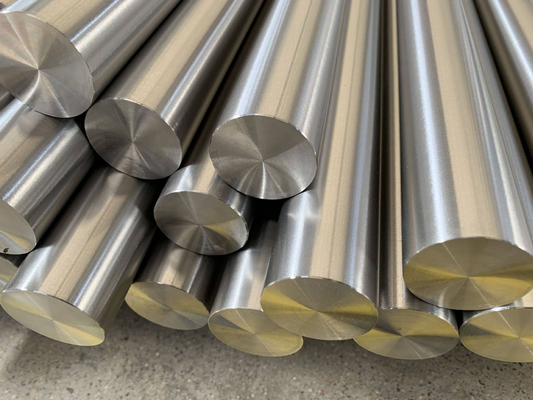

| Formas Disponíveis | Placas, Folhas, Barras, Forjados, Formas Personalizadas |

| Faixa de Espessura da Placa | 6 - 150 mm |

| Faixa de Largura da Placa | 1000 - 4000 mm |

| Faixa de Comprimento da Placa | 2000 - 18000 mm |

| Conformidade com Normas | EN 10225, API 2H, DNV GL, ABS, LR, BV |

| Acabamento de Superfície | Laminado a Quente, Normalizado, Jateado, Desincrustado |

| Tolerância Dimensional | ±0.5mm espessura, ±5mm largura/comprimento |

| Tolerância de Planicidade | ≤ 5mm/m |

| Condição da Borda | Borda de Serralheria, Borda Aparada, Corte a Plasma |

| Tratamento Térmico | Normalizado (N), Normalizado + Temperado (NT) |

| Requisitos de Teste | Teste de Impacto, UT, MT, Análise Química |

Vamos Criar Sucesso para o Seu Projeto

Equipe Profissional, Produtos Premium, Serviço Completo - O Sucesso do Seu Projeto é Nossa Missão

Our Advantages in Processing EH40

Tecnologia Avançada de Laminação Controlada

MetalZenith emprega processos de laminação controlados por precisão com sistemas de resfriamento controlados por computador para alcançar um refino de grão ideal e propriedades mecânicas uniformes em toda a espessura do aço, garantindo desempenho consistente em ambientes offshore exigentes.

Laboratório de Testes de Qualidade Abrangente

Nossa instalação de testes de última geração realiza testes mecânicos, químicos e não destrutivos extensivos, incluindo inspeção ultrassônica, teste de partículas magnéticas e teste de impacto Charpy a baixa temperatura para garantir a integridade do material e a conformidade com os padrões internacionais de offshore.

Cadeia de Suprimentos Global & Soluções Personalizadas

MetalZenith oferece soluções de fornecimento flexíveis com locais de inventário estratégicos em todo o mundo, serviços de corte e usinagem personalizados, e suporte técnico para requisitos específicos de projetos, garantindo entrega pontual e utilização ideal de materiais para projetos de construção offshore.

SEU CONFIÁVEL AÇO

PARCEIRO DE MANUFATURA

Quick Inquiry

Indústrias que Atendemos

Soluções de aço profissionais em grandes indústrias

Qualificações e Certificações