20 Anos de Experiência | 1000+ Parceiros de Marca | Personalização Completa

Temos 20 anos de experiência na indústria, fizemos parceria com mais de 1.000 marcas e apoiamos quaisquer necessidades de personalização.

Technical Specifications

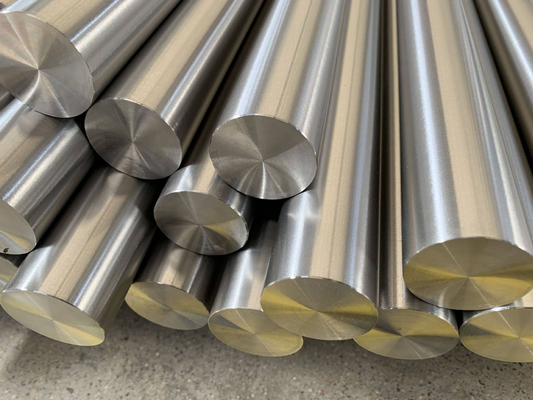

Product Overview

Características Metalúrgicas

O aço marinho DH32 apresenta uma microestrutura ferrítica-perlítica de grão fino, obtida através de laminação controlada e tratamento térmico de normalização. A adição de elementos de microligadura, como nióbio, vanádio e titânio, proporciona refino de grão e endurecimento por precipitação, resultando em um excelente equilíbrio entre resistência e tenacidade, essencial para aplicações marinhas.

Processo de Tratamento Térmico

A MetalZenith emprega um processo preciso de tratamento térmico de normalização, onde o aço é aquecido a 900-950°C e resfriado ao ar para alcançar propriedades mecânicas ideais. Este processo garante uma estrutura de grão uniforme, elimina tensões residuais e fornece propriedades mecânicas consistentes em toda a espessura do material. Nossos sistemas avançados de controle de forno mantêm a uniformidade da temperatura dentro de ±5°C.

Excelência no Processo de Fabricação

Nossa instalação de produção de última geração utiliza fusão em forno de arco elétrico, seguida de refino em panela e desgasificação a vácuo para alcançar um conteúdo ultra-baixo de enxofre e fósforo. O processo de laminação controlada, com temperatura de laminação final entre 850-900°C, garante um refino de grão ideal e desenvolvimento de propriedades mecânicas. Sistemas avançados de resfriamento online fornecem controle preciso da temperatura durante o processo de normalização.

Padrões de Qualidade & Testes

Cada lote passa por testes abrangentes, incluindo análise química por espectroscopia de emissão óptica, testes de tração, testes de impacto Charpy V-notch em temperaturas especificadas, testes de dureza e exame ultrassônico. Testes de soldabilidade e resistência a trincas induzidas por hidrogênio (HIC) garantem a adequação para estruturas soldadas marinhas. Todos os produtos são fornecidos com Certificados de Teste de Fabrica (MTC) 3.1 de acordo com a EN 10204.

Resistência à Corrosão & Proteção

Embora o DH32 seja projetado principalmente para resistência estrutural, a MetalZenith pode fornecer resistência à corrosão aprimorada através da adição controlada de cobre e tratamentos de superfície especializados. Nossa equipe técnica fornece orientação sobre sistemas de revestimento protetores apropriados e proteção catódica para uma vida útil prolongada em ambientes marinhos.

🧪 Chemical Composition

| Elemento | Composição (%) |

|---|---|

| Carbono (C) | ≤ 0.18 |

| Manganês (Mn) | 0.90 - 1.60 |

| Silício (Si) | 0.10 - 0.50 |

| Fósforo (P) | ≤ 0.035 |

| Enxofre (S) | ≤ 0.035 |

| Alumínio (Al) | ≥ 0.015 |

| Nióbio (Nb) | 0.02 - 0.05 |

| Vanádio (V) | 0.05 - 0.10 |

| Titânio (Ti) | 0.02 - 0.05 |

| Cobre (Cu) | ≤ 0.35 |

| Cromo (Cr) | ≤ 0.20 |

| Níquel (Ni) | ≤ 0.40 |

| Molibdênio (Mo) | ≤ 0.08 |

⚙️ Mechanical Properties

| Propriedade | Valor |

|---|---|

| Limite de Esforço (ReH) | ≥ 315 MPa |

| Limite de Resistência (Rm) | 440 - 590 MPa |

| Alongamento (A5) | ≥ 22% |

| Energia de Impacto (KV a 0°C) | ≥ 34 J |

| Energia de Impacto (KV a -20°C) | ≥ 24 J |

| Dureza Brinell (HB) | 150 - 230 |

| Módulo de Young | 210 GPa |

| Razão de Poisson | 0.30 |

| Limite de Fadiga (107 ciclos) | 200 MPa |

| Tenacidade à Fratura (KIC) | 150 MPa·m1/2 |

🔬 Physical Properties

| Propriedade | Valor |

|---|---|

| Densidade | 7.85 g/cm³ |

| Ponto de Fusão | 1510°C |

| Condutividade Térmica (20°C) | 54 W/m·K |

| Coeficiente de Expansão Térmica (20-100°C) | 12×10-6/K |

| Capacidade Calorífica Específica | 500 J/kg·K |

| Resistividade Elétrica (20°C) | 0.16 µΩ·m |

| Permeabilidade Magnética | Ferromagnético |

| Temperatura de Curie | 770°C |

| Difusividade Térmica | 13.7 mm²/s |

| Emissividade | 0.85 |

📏 Product Specifications

| Especificação | Detalhes |

|---|---|

| Formas Disponíveis | Placas, Folhas, Barras, Perfis, Forjados |

| Faixa de Espessura da Placa | 6 - 150 mm |

| Faixa de Espessura da Folha | 3 - 6 mm |

| Largura Máxima | 3500 mm |

| Comprimento Máximo | 18000 mm |

| Conformidade com Normas | EN 10225, ASTM A131, JIS G3136, GB/T 712 |

| Aprovação de Sociedade de Classificação | ABS, DNV-GL, LR, BV, CCS, NK, KR |

| Acabamento de Superfície | Laminado a Quente, Normalizado, Jateado |

| Tolerância Dimensional | ±0.5mm de espessura, ±5mm de largura/comprimento |

| Condição da Borda | Borda de Laminagem, Borda Cortada, Corte a Plasma |

Vamos Criar Sucesso para o Seu Projeto

Equipe Profissional, Produtos Premium, Serviço Completo - O Sucesso do Seu Projeto é Nossa Missão

Our Advantages in Processing DH32

Processamento Termomecânico Avançado

MetalZenith emprega tecnologia de laminação controlada e normalização de ponta com controle preciso de temperatura para alcançar um refino de grão ideal e propriedades mecânicas uniformes em toda a estrutura do aço, garantindo desempenho consistente em ambientes marinhos exigentes.

Sistema Abrangente de Controle de Qualidade

Nossas instalações de teste de última geração incluem testes ultrassônicos avançados, testes de impacto em temperaturas sub-zero e análise química completa para garantir conformidade com sociedades de classificação marinha internacionais e assegurar a superioridade da confiabilidade dos materiais.

Cadeia de Suprimentos Global e Personalização

MetalZenith oferece opções de personalização flexíveis, incluindo dimensões específicas, tratamentos de superfície e cronogramas de entrega. Nossa rede logística global garante entrega pontual em todo o mundo, com documentação completa e pacotes de certificação adaptados às necessidades dos clientes.

SEU CONFIÁVEL AÇO

PARCEIRO DE MANUFATURA

Quick Inquiry

Indústrias que Atendemos

Soluções de aço profissionais em grandes indústrias

Qualificações e Certificações