20 Anos de Experiência | 1000+ Parceiros de Marca | Personalização Completa

Temos 20 anos de experiência na indústria, fizemos parceria com mais de 1.000 marcas e apoiamos quaisquer necessidades de personalização.

Technical Specifications

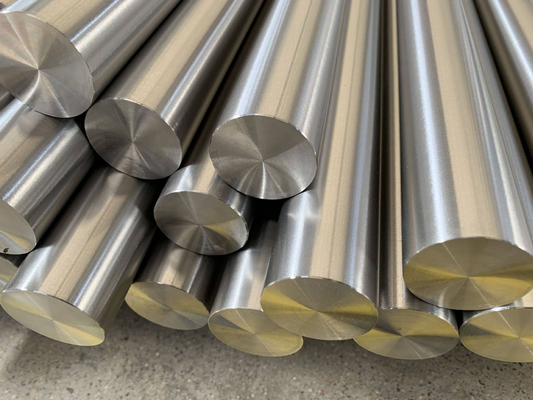

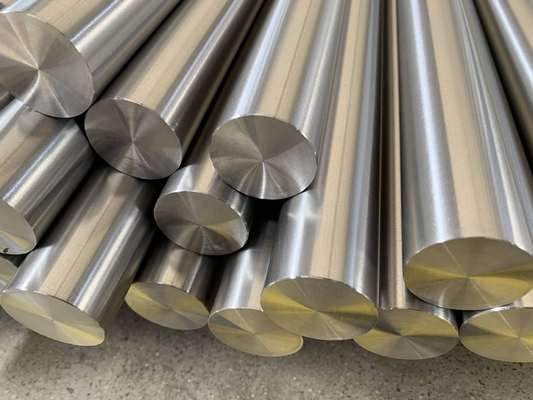

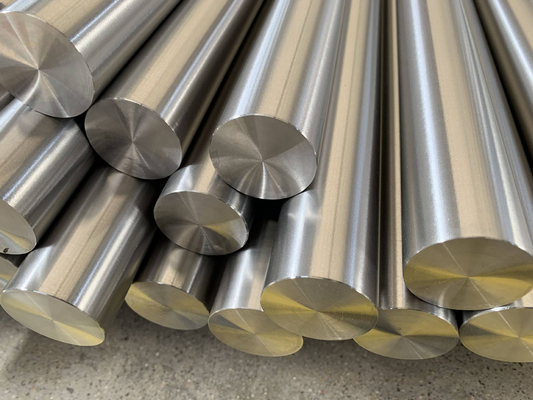

Product Overview

Características Metalúrgicas

O aço EH32 apresenta uma microestrutura ferrítica-perlítica de grão fino, obtida através de processamento termomecânico controlado. A resistência aprimorada do aço é derivada do refino de grãos, fortalecimento por solução sólida e precipitação controlada de elementos microaleantes, como nióbio e vanádio.

Processo de Tratamento Térmico

A MetalZenith emprega técnicas avançadas de laminação controlada seguidas de resfriamento acelerado para alcançar propriedades mecânicas ideais. O aço é tipicamente fornecido na condição normalizada ou processada termomecanicamente (TMCP), com temperaturas de acabamento entre 850-950°C e taxas de resfriamento controladas para garantir o desenvolvimento microestrutural adequado.

Processo de Fabricação

Nossa produção de aço EH32 utiliza fusão em forno de arco elétrico com processos de refino secundário, incluindo tratamento em forno de panela e desgasificação a vácuo. O aço passa por fundição contínua seguida de laminação controlada em nosso moderno laminador de tiras a quente, com controle preciso de temperatura e sistemas de resfriamento acelerado.

Padrões de Qualidade & Testes

Cada lote de aço EH32 passa por testes abrangentes, incluindo análise química, teste de tração, teste de impacto em temperaturas especificadas, medição de dureza e inspeção ultrassônica. A MetalZenith mantém a certificação ISO 9001:2015 e segue os requisitos da sociedade de classificação marítima para rastreabilidade de materiais e documentação de qualidade.

Soldabilidade & Fabricação

O aço EH32 apresenta excelente soldabilidade, com valores de equivalente de carbono tipicamente abaixo de 0,40%. O aço pode ser soldado usando processos convencionais de soldagem a arco, incluindo SMAW, GMAW e SAW. O pré-aquecimento pode ser necessário para seções grossas, tipicamente 100-150°C, dependendo da espessura e das condições ambientais.

🧪 Chemical Composition

| Elemento | Composição (%) |

|---|---|

| Carbono (C) | ≤ 0.18 |

| Manganês (Mn) | 0.90 - 1.60 |

| Silício (Si) | 0.10 - 0.50 |

| Fósforo (P) | ≤ 0.035 |

| Enxofre (S) | ≤ 0.035 |

| Cromo (Cr) | ≤ 0.20 |

| Níquel (Ni) | ≤ 0.40 |

| Molibdênio (Mo) | ≤ 0.08 |

| Cobre (Cu) | ≤ 0.35 |

| Alumínio (Al) | ≥ 0.015 |

| Nióbio (Nb) | ≤ 0.05 |

| Vanádio (V) | ≤ 0.10 |

| Titânio (Ti) | ≤ 0.02 |

⚙️ Mechanical Properties

| Propriedade | Valor |

|---|---|

| Limite de Esforço (ReH) | ≥ 315 MPa |

| Limite de Tração (Rm) | 440 - 590 MPa |

| Alongamento (A5) | ≥ 22% |

| Energia de Impacto (KV a -20°C) | ≥ 34 J |

| Energia de Impacto (KV a -40°C) | ≥ 24 J |

| Dureza Brinell (HB) | 150 - 220 |

| Módulo de Young | 210 GPa |

| Módulo de Cisalhamento | 81 GPa |

| Razão de Poisson | 0.30 |

| Limite de Fadiga (107 ciclos) | 200 MPa |

| Tenacidade à Fratura (KIC) | 150 MPa·m1/2 |

🔬 Physical Properties

| Propriedade | Valor |

|---|---|

| Densidade | 7.85 g/cm³ |

| Ponto de Fusão | 1510°C |

| Condutividade Térmica (20°C) | 54 W/m·K |

| Coeficiente de Expansão Térmica (20-100°C) | 12×10-6/K |

| Capacidade Calorífica Específica | 500 J/kg·K |

| Resistividade Elétrica (20°C) | 0.16 µΩ·m |

| Permeabilidade Magnética | Ferromagnético |

| Temperatura de Curie | 770°C |

| Difusividade Térmica | 13.7 mm²/s |

| Coeficiente de Expansão Linear (0-100°C) | 11.5×10-6/K |

📏 Product Specifications

| Especificação | Detalhes |

|---|---|

| Formas Disponíveis | Placas, Folhas, Barras, Perfis, Forjados |

| Faixa de Espessura da Placa | 6 - 150 mm |

| Faixa de Espessura da Folha | 2 - 6 mm |

| Faixa de Largura | 1000 - 4000 mm |

| Faixa de Comprimento | 2000 - 18000 mm |

| Conformidade com Normas | EN 10225, ASTM A131, JIS G3136, GB/T 712 |

| Acabamento de Superfície | Laminado a Quente, Normalizado, Jateado |

| Condição da Borda | Borda de Laminagem, Borda Cortada, Borda Cortada a Laser |

| Tolerância de Espessura | ± 0.3 mm (t ≤ 40mm), ± 0.05t (t > 40mm) |

| Tolerância de Largura | ± 10 mm |

| Tolerância de Comprimento | ± 25 mm |

| Planicidade | ≤ 5 mm/m |

Vamos Criar Sucesso para o Seu Projeto

Equipe Profissional, Produtos Premium, Serviço Completo - O Sucesso do Seu Projeto é Nossa Missão

Our Advantages in Processing EH32

Processamento Termomecânico Avançado

MetalZenith emprega tecnologias de laminação controlada e resfriamento acelerado de ponta para alcançar um refinamento microestrutural ideal no aço EH32, resultando em propriedades mecânicas superiores e maior tenacidade a baixa temperatura para aplicações marinhas.

Certificação Marinha Abrangente

Nossa instalação de produção de aço EH32 mantém certificações de todas as principais sociedades de classificação marítima, incluindo ABS, DNV-GL, Lloyd's Register e Bureau Veritas, garantindo total conformidade com os padrões e regulamentos marítimos internacionais.

Soluções Marinhas Personalizadas

MetalZenith oferece amplas capacidades de personalização para produtos de aço EH32, incluindo tratamentos térmicos especializados, tolerâncias dimensionais precisas e propriedades mecânicas sob medida para atender a requisitos específicos de engenharia marinha e especificações de design de embarcações.

SEU CONFIÁVEL AÇO

PARCEIRO DE MANUFATURA

Quick Inquiry

Indústrias que Atendemos

Soluções de aço profissionais em grandes indústrias

Qualificações e Certificações