20年の経験 | 1000以上のブランドパートナー | 完全なカスタマイズ

私たちは20年の業界経験があり、1,000以上のブランドと提携し、あらゆるカスタマイズニーズをサポートしています。

Technical Specifications

Product Overview

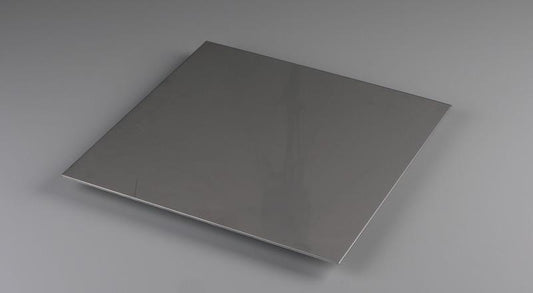

漬け込まれたオイル鋼板は、高品質の炭素鋼から製造され、特別な表面処理プロセスを経ます。漬け込みプロセスでは、酸溶液を使用してミルスケールと表面酸化物を除去し、その後、腐食を防ぎ、表面品質を向上させるためにオイルを塗布します。

主な特徴:

- スケールのない外観で優れた表面仕上げ

- オイルコーティングによる腐食抵抗の向上

- 優れた成形性と溶接性

- 一貫した厚さと平坦度の公差

- 塗装およびコーティング用途に即応

製造プロセス:熱間圧延鋼は、塩酸または硫酸浴で漬け込まれ、スケールを除去した後、すすぎ、乾燥し、保管および輸送中の保護のために薄いオイル層でコーティングされます。

用途:自動車部品、家電製造、建材、一般的な加工、スタンピングおよび成形作業、塗装またはコーティング前に優れた表面仕上げを必要とする用途。

🧪 Chemical Composition

化学組成:

| 元素 | 最小 % | 最大 % | 典型 % | ASTM A1011 要件 |

|---|---|---|---|---|

| 炭素 (C) | - | 0.15 | 0.08 | ≤ 0.15 |

| マンガン (Mn) | 0.30 | 0.90 | 0.60 | 0.30-0.90 |

| リン (P) | - | 0.030 | 0.015 | ≤ 0.030 |

| 硫黄 (S) | - | 0.035 | 0.020 | ≤ 0.035 |

| シリコン (Si) | - | 0.40 | 0.15 | ≤ 0.40 |

| アルミニウム (Al) | 0.020 | 0.080 | 0.040 | 0.020-0.080 |

| 窒素 (N) | - | 0.009 | 0.005 | ≤ 0.009 |

| 銅 (Cu) | - | 0.20 | 0.10 | ≤ 0.20 |

| 鉄 (Fe) | バランス | バランス | 98.8 | バランス |

⚙️ Mechanical Properties

機械的特性:

| 特性 | ASTM 要件 | 典型値 | 試験方法 | 温度 |

|---|---|---|---|---|

| 引張強度 | 270-410 MPa | 340 MPa | ASTM A370 | 室温 |

| 降伏強度 | 140 MPa 最小 | 180 MPa | ASTM A370 | 室温 |

| 伸び | 22% 最小 | 28% | ASTM A370 | 室温 |

| 硬度 (ブリネル) | - | 120 HB | ASTM E10 | 室温 |

| 硬度 (ロックウェル B) | - | 65 HRB | ASTM E18 | 室温 |

| 弾性係数 | - | 200 GPa | ASTM E111 | 室温 |

| 衝撃エネルギー (シャルピー V) | - | 150+ J | ASTM E23 | 室温 |

🔬 Physical Properties

物理特性:

| 特性 | 値 | 単位 | 温度 | 試験基準 |

|---|---|---|---|---|

| 密度 | 7.85 | g/cm3 | 20°C | ASTM B311 |

| 融点 | 1510-1540 | °C | - | DSC分析 |

| 熱伝導率 | 50.2 | W/m·K | 100°C | ASTM E1461 |

| 比熱 | 460 | J/kg·K | 0-100°C | ASTM C351 |

| 線膨張 | 11.7 | μm/m·K | 0-100°C | ASTM E228 |

| 電気抵抗率 | 170 | n|°¤m | 20°C | ASTM B193 |

| 磁気透過率 | 高い | μ/μ₀ | 室温 | ASTM A342 |

| キュリー温度 | 770 | °C | - | 強磁性 |

📏 Product Specifications

Product Specifications:

| 仕様 | 利用可能範囲 | 標準サイズ | カスタム利用可能 | 公差 |

|---|---|---|---|---|

| 厚さ | 1.2mm - 12.7mm | 様々 | はい | ±0.05mm |

| 幅 | 600mm - 2100mm | 1250mm, 1500mm | はい | ±3mm |

| 長さ | 2000mm - 12000mm | 6000mm | はい | +50mm/-0mm |

| 表面仕上げ | ピクルド&オイル仕上げ | P&O標準 | 特別仕上げ | Ra ≤ 1.6μm |

| エッジ状態 | ミルエッジ、スリットエッジ | ミルエッジ | はい | ASTM A1011 |

| 平坦度 | ≤ 5mm/m | 標準 | 精密平坦 | ASTM A1011 |

| 規格適合 | ASTM A1011, A569, A635 | A1011 | 複数 | 完全適合 |

| 鋼種 | CSタイプA, B, C | CSタイプB | はい | グレード認証済み |

| 試験証明書 | ミルTC, EN 10204 3.1 | ミルTC | はい | 標準 |

| 包装 | コイル、カットシート | カットシート | カスタム | 輸出標準 |

あなたのプロジェクトの成功を共に創りましょう

プロフェッショナルチーム、プレミアム製品、完全なサービス - あなたのプロジェクトの成功は私たちの使命です

Our Advantages in Processing 漬けられた油の鋼板

優れた表面清浄度

ピクルス処理プロセスは、化学処理を通じて表面の汚染物質、ミルスケール、錆を効果的に除去し、その結果、次の加工および仕上げ作業に最適な非常にクリーンな鋼の表面を得ることができます。

強化された腐食防止

ピクルス処理とその後の正確な油の適用の組み合わせは、腐食に対する二重の保護バリアを作り出し、材料の保存期間を大幅に延ばし、環境要因に対する優れた耐性を提供します。

処理品質の向上

ピクルスとオイルプロセスによって得られる滑らかで清潔な表面は、より良い塗料の密着性、容易な成形操作、および向上した溶接性を確保し、要求の厳しい製造アプリケーションに最適です。

あなたの信頼できる 鋼

製造パートナー

20

年数の経験

鋼鉄製造および流通のリーディング

1000以上

ブランドパートナー

グローバル業界のリーダーに信頼されています

完全

カスタマイズ

すべてのプロジェクトに合わせたソリューション

50M+

配達されたトン数

高品質の鋼製品を世界中に

95%

クライアントの維持

長期的なパートナーシップの成功

ISO 9001

認証された品質

国際標準の遵守

20

年数の経験

鋼鉄製造および流通のリーディング

1000以上

ブランドパートナー

グローバル業界のリーダーに信頼されています

完全

カスタマイズ

すべてのプロジェクトに合わせたソリューション

50M+

配達されたトン数

高品質の鋼製品を世界中に

95%

クライアントの維持

長期的なパートナーシップの成功

ISO 9001

認証された品質

国際標準の遵守

お問い合わせ

クイックお問い合わせ

最小注文数量:3トン

私たちが提供する業界

主要産業向けのプロフェッショナルな鋼ソリューション

資格と認証