20年の経験 | 1000以上のブランドパートナー | 完全なカスタマイズ

私たちは20年の業界経験があり、1,000以上のブランドと提携し、あらゆるカスタマイズニーズをサポートしています。

Technical Specifications

Product Overview

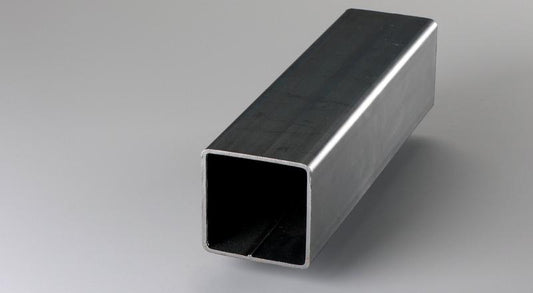

ブラックスチールパイプは、高品質の炭素鋼から製造され、製造プロセス中に形成される特有の黒い酸化コーティングを持っています。このコーティングは基本的な腐食保護を提供し、パイプに独特の暗い外観を与えます。ブラックスチールパイプは、ガス配管、水供給、一般的な構造用途に広く使用されています。

主な特徴:

- 一般的な配管用途に対するコスト効果の高いソリューション

- 良好な溶接性と加工性

- ねじ接続と溶接接続の両方に適している

- さまざまなスケジュールとサイズで利用可能

- 主要な国際基準に準拠

製造プロセス:電気抵抗溶接(ERW)またはシームレスプロセスを通じて製造され、耐久性と腐食抵抗を向上させるために製造中に黒い酸化コーティングが適用されます。

用途:ガス配分システム、水供給ライン、消防スプリンクラーシステム、HVAC用途、構造支持、フェンシング、そして中程度の腐食抵抗が必要な一般的な産業配管。

🧪 Chemical Composition

Chemical Composition:

| 元素 | 最小 % | 最大 % | 典型 % | ASTM A53 要求 |

|---|---|---|---|---|

| 炭素 (C) | - | 0.30 | 0.18 | ≤ 0.30 |

| マンガン (Mn) | 0.29 | 1.06 | 0.65 | 0.29-1.06 |

| リン (P) | - | 0.05 | 0.025 | ≤ 0.05 |

| 硫黄 (S) | - | 0.06 | 0.035 | ≤ 0.06 |

| シリコン (Si) | - | 0.40 | 0.25 | ≤ 0.40 |

| 銅 (Cu) | - | 0.40 | 0.20 | ≤ 0.40 |

| ニッケル (Ni) | - | 0.40 | 0.15 | ≤ 0.40 |

| クロム (Cr) | - | 0.40 | 0.12 | ≤ 0.40 |

| 鉄 (Fe) | バランス | バランス | 98.5 | バランス |

⚙️ Mechanical Properties

機械的特性:

| 特性 | ASTM 要件 | 典型値 | 試験方法 | 温度 |

|---|---|---|---|---|

| 引張強度 | 415 MPa 最小 | 450 MPa | ASTM A370 | 室温 |

| 降伏強度 | 240 MPa 最小 | 275 MPa | ASTM A370 | 室温 |

| 伸び | 23% 最小 | 28% | ASTM A370 | 室温 |

| 硬度 (ブリネル) | - | 130 HB | ASTM E10 | 室温 |

| 硬度 (ロックウェル B) | - | 75 HRB | ASTM E18 | 室温 |

| 弾性係数 | - | 210 GPa | ASTM E111 | 室温 |

| 衝撃エネルギー (シャルピー V) | - | 80+ J | ASTM E23 | 室温 |

🔬 Physical Properties

物理特性:

| 特性 | 値 | 単位 | 温度 | 試験基準 |

|---|---|---|---|---|

| 密度 | 7.85 | g/cm3 | 20°C | ASTM B311 |

| 融点 | 1510-1540 | °C | - | DSC分析 |

| 熱伝導率 | 50-60 | W/m·K | 100°C | ASTM E1461 |

| 比熱 | 460 | J/kg·K | 0-100°C | ASTM C351 |

| 線膨張 | 11.7 | μm/m·K | 0-100°C | ASTM E228 |

| 電気抵抗率 | 100-200 | n|°¤m | 20°C | ASTM B193 |

| 磁気透過率 | 高い | μ/μ₀ | 室温 | ASTM A342 |

| キュリー温度 | 770 | °C | - | 強磁性 |

📏 Product Specifications

Product Specifications:

| 仕様 | 利用可能範囲 | 標準長さ | カスタム利用可能 | 許容差 |

|---|---|---|---|---|

| 外径 (OD) | 15mm - 610mm | 様々 | はい | ±1.0mm |

| 壁厚 | 2.0mm - 22mm | 様々 | はい | ±12.5% |

| 長さ | 3m - 12m | 6m | はい | +100mm/-0mm |

| 表面仕上げ | 黒、塗装、油処理 | 黒 | はい | 標準ミル |

| 溶接タイプ | ERW、LSAW、SSAW | ERW | すべてのタイプ | API標準 |

| エンド接続 | 平面、傾斜、ねじ切り | 平面 | はい | ASME B36.10 |

| 規格遵守 | ASTM A53、A106、API 5L | A53 | 複数 | 完全遵守 |

| 圧力定格 | スケジュール 40 - 160 | スケジュール 40 | はい | ASME B31.1 |

| 試験証明書 | ミル TC、EN 10204 3.1 | ミル TC | はい | 標準 |

| 包装 | バンドル、バラ、コンテナ | バンドル | カスタム | 輸出標準 |

あなたのプロジェクトの成功を共に創りましょう

プロフェッショナルチーム、プレミアム製品、完全なサービス - あなたのプロジェクトの成功は私たちの使命です

Our Advantages in Processing 黒鋼パイプ

優れた腐食防止

製造プロセスは、制御された酸化を通じて保護的な酸化鉄コーティングを生成し、追加の処理なしで自然な耐腐食性を提供します。この黒い表面層は、環境要因に対するバリアとして機能し、パイプのサービス寿命を延ばします。

精密鋼圧延プロセス

高度な圧延技術により、パイプ全長にわたって均一な壁厚と正確な寸法精度が確保されます。制御された製造プロセスは、一貫した材料特性と構造的完全性を提供し、信頼性の高い性能を実現します。

熱処理の最適化

生産中の特殊熱処理は、鋼の機械的特性を向上させ、最適な強度対重量比と改善された延性をもたらします。このプロセスにより、パイプは高圧および温度変動に耐えることができます。

あなたの信頼できる 鋼

製造パートナー

20

年数の経験

鋼鉄製造および流通のリーディング

1000以上

ブランドパートナー

グローバル業界のリーダーに信頼されています

完全

カスタマイズ

すべてのプロジェクトに合わせたソリューション

50M+

配達されたトン数

高品質の鋼製品を世界中に

95%

クライアントの維持

長期的なパートナーシップの成功

ISO 9001

認証された品質

国際標準の遵守

20

年数の経験

鋼鉄製造および流通のリーディング

1000以上

ブランドパートナー

グローバル業界のリーダーに信頼されています

完全

カスタマイズ

すべてのプロジェクトに合わせたソリューション

50M+

配達されたトン数

高品質の鋼製品を世界中に

95%

クライアントの維持

長期的なパートナーシップの成功

ISO 9001

認証された品質

国際標準の遵守

お問い合わせ

クイックお問い合わせ

最小注文数量:3トン

私たちが提供する業界

主要産業向けのプロフェッショナルな鋼ソリューション

資格と認証