20年の経験 | 1000以上のブランドパートナー | 完全なカスタマイズ

私たちは20年の業界経験があり、1,000以上のブランドと提携し、あらゆるカスタマイズニーズをサポートしています。

Technical Specifications

Product Overview

冶金特性

GB 00Cr22Ni5Mo3Nは、約50%のオーステナイトと50%のフェライト相のバランスの取れた微細構造を持つ低合金デュプレックスステンレス鋼です。この二相構造は、従来のオーステナイト系ステンレス鋼と比較して、優れた強度対重量比と優れた耐腐食性を提供します。窒素の添加は、機械的特性とピッティング耐性の両方を向上させます。

熱処理プロセス

MetalZenithは、1020-1100°Cでの正確な溶体アニーリングを行い、その後急冷して最適な相バランスを達成します。制御された冷却速度は、有害な金属間化合物相の析出を防ぎ、所望のオーステナイト-フェライト比を維持します。アニーリング後の酸洗いは、熱による色合いを除去し、均一な表面仕上げを確保します。

製造プロセスの卓越性

当社の統合生産プロセスは、プレミアム原材料を使用した真空誘導溶解から始まり、クリーンさを向上させるために電気スラグ再溶解が続きます。熱間加工操作は、相の不均衡を防ぐために950-1200°Cの温度範囲内で慎重に制御されます。冷間加工能力には、デュプレックス鋼用に設計された特殊工具を使用した精密圧延、引き抜き、機械加工が含まれます。

品質基準と試験

MetalZenithは、ASTM A240、EN 10088、JIS G4305などの国際基準に準拠しています。包括的な試験プロトコルには、光学放出分光法による化学分析、ASTM A370に基づく機械試験、磁気法によるフェライト含有量測定、ASTM G48によるピッティング耐性評価を含む腐食試験が含まれます。各バッチには、完全なトレーサビリティを持つ材料試験証明書が付与されます。

🧪 Chemical Composition

| 元素 | 組成 (%) |

|---|---|

| 炭素 (C) | ≤ 0.030 |

| シリコン (Si) | ≤ 1.00 |

| マンガン (Mn) | ≤ 2.00 |

| リン (P) | ≤ 0.030 |

| 硫黄 (S) | ≤ 0.020 |

| クロム (Cr) | 21.0 - 23.0 |

| ニッケル (Ni) | 4.5 - 6.5 |

| モリブデン (Mo) | 2.5 - 3.5 |

| 窒素 (N) | 0.08 - 0.20 |

| 銅 (Cu) | ≤ 0.50 |

| タングステン (W) | ≤ 0.50 |

⚙️ Mechanical Properties

| 特性 | 値 |

|---|---|

| 引張強度 (Rm) | ≥ 620 MPa |

| 降伏強度 (Rp0.2) | ≥ 450 MPa |

| 伸び (A5) | ≥ 25% |

| 硬度 (HB) | ≤ 290 |

| 衝撃エネルギー (KV2) 20°Cにおける | ≥ 60 J |

| 衝撃エネルギー (KV2) -40°Cにおける | ≥ 40 J |

| ヤング率 | 200 GPa |

| 疲労限界 (10^7 サイクル) | 280 MPa |

| ポアソン比 | 0.28 |

| せん断弾性率 | 78 GPa |

🔬 Physical Properties

| プロパティ | 値 |

|---|---|

| 密度 | 7.8 g/cm³ |

| 融点 | 1350-1400°C |

| 20°Cでの熱伝導率 | 14 W/m·K |

| 100°Cでの熱伝導率 | 16 W/m·K |

| 熱膨張(20-100°C) | 13×10-6/K |

| 熱膨張(20-300°C) | 14×10-6/K |

| 比熱容量 | 500 J/kg·K |

| 20°Cでの電気抵抗率 | 0.85 µΩ·m |

| 磁気透過率 | 1.5 - 2.0 |

| キュリー温度 | -50°C |

📏 Product Specifications

| 仕様 | 利用可能なオプション |

|---|---|

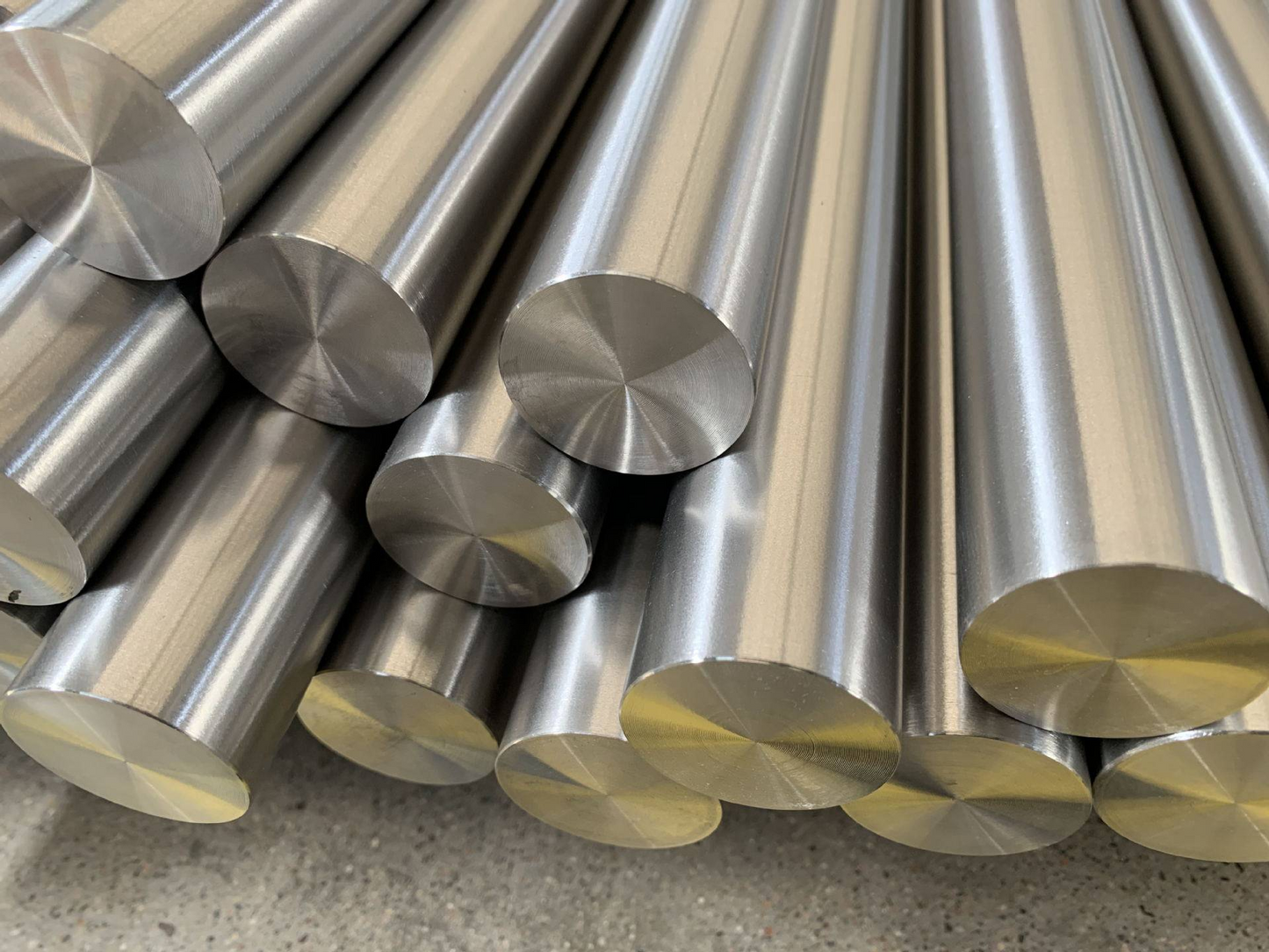

| 製品形状 | 丸棒、平棒、板、シート、チューブ、パイプ、鍛造品 |

| 丸棒直径 | 6mm - 300mm |

| 平棒寸法 | 10×3mm - 200×50mm |

| 板厚 | 3mm - 100mm |

| シート厚 | 0.5mm - 6mm |

| チューブ外径 | 6mm - 219mm |

| 規格適合 | GB/T 1220, ASTM A240, EN 10088, JIS G4305 |

| 表面仕上げ | 熱間圧延、冷間圧延、酸洗い、研磨、機械加工 |

| 公差クラス | h9、h11(棒用);板用は±0.1mm |

| 長さオプション | 標準長さ3m、6m、12mまたはカットサイズ |

あなたのプロジェクトの成功を共に創りましょう

プロフェッショナルチーム、プレミアム製品、完全なサービス - あなたのプロジェクトの成功は私たちの使命です

Our Advantages in Processing GB 00Cr22Ni5Mo3N

高度な真空溶融技術

MetalZenithは、最先端の真空誘導溶解(VIM)および電気スラグ再溶解(ESR)プロセスを採用して、正確な化学組成の制御を実現し、異物を排除することで、GB 00Cr22Ni5Mo3Nの製造において優れた材料の純度と一貫した機械的特性を保証します。

包括的な品質管理システム

私たちのISO 9001:2015認証の品質管理システムには、高度な分光分析、機械的試験、および耐腐食性評価が含まれています。すべてのバッチは、国際基準および顧客仕様への適合を保証するために、最先端の機器を使用して厳格な検査を受けます。

カスタム処理とグローバル供給

MetalZenithは、精密加工、熱処理、表面仕上げサービスを含む広範なカスタマイズ機能を提供しています。私たちのグローバルな流通ネットワークは、世界中の顧客へのジャストインタイム配送を伴う信頼性の高いサプライチェーン管理を確保し、包括的な技術支援によってサポートされています。

あなたの信頼できる 鋼

製造パートナー

クイックお問い合わせ

私たちが提供する業界

主要産業向けのプロフェッショナルな鋼ソリューション

資格と認証