20年の経験 | 1000以上のブランドパートナー | 完全なカスタマイズ

私たちは20年の業界経験があり、1,000以上のブランドと提携し、あらゆるカスタマイズニーズをサポートしています。

Technical Specifications

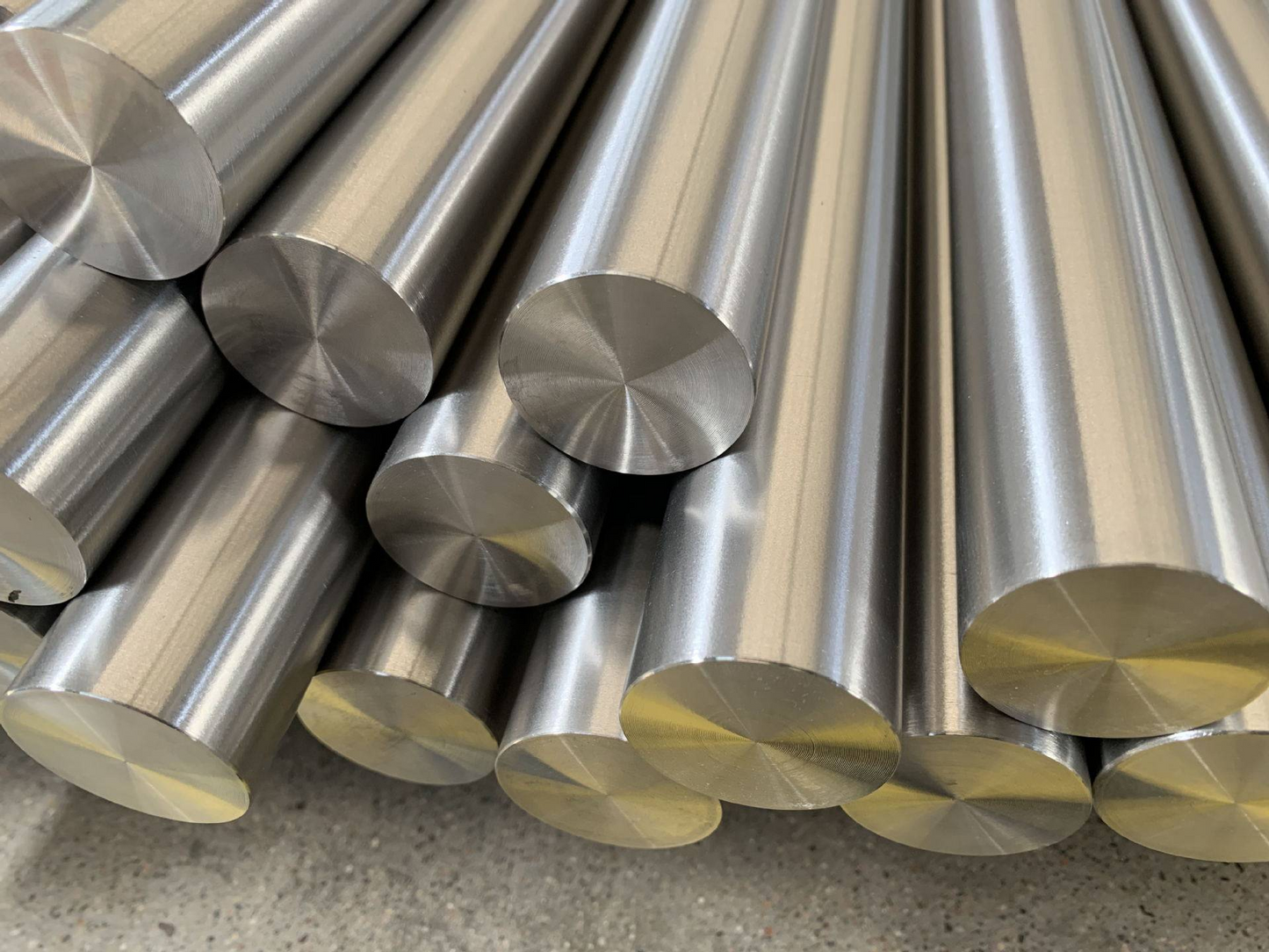

Product Overview

冶金特性

EN 1.4462は、約50%のオーステナイトと50%のフェライト相からなるバランスの取れた二相微細構造を示します。この独特の二相構造は、従来のオーステナイト系ステンレス鋼と比較して、優れた強度対重量比とストレス腐食割れに対する優れた耐性を提供します。高いクロム、モリブデン、窒素含有量は、塩化物環境における優れたピッティングおよびクレバス腐食抵抗を保証します。

熱処理プロセス

溶解アニーリングは1020-1100°Cで行われ、その後、水または空気中で急冷されて最適な二相微細構造を維持します。MetalZenithの制御冷却プロセスは、有害な金属間化合物相の析出を防ぎながら、適切なフェライト-オーステナイトバランスを確保します。溶接部品の応力緩和のために、1050°Cでの溶接後熱処理が適用される場合があります。

製造プロセスの卓越性

MetalZenithは、優れた化学的均一性と清浄度を達成するために、先進的な真空誘導溶融(VIM)技術を採用しています。私たちの熱機械制御加工(TMCP)は、最適な粒子細化と機械的特性を保証します。熱間加工は950-1150°Cの間で行われ、冷間加工能力により、制御された変形を通じて強度が向上します。

品質基準と試験

すべてのEN 1.4462製品は、光学放出分光法による化学分析、ASTM A370に基づく機械試験、磁気法によるフェライト含有量測定、ASTM G48に基づく腐食試験を含む包括的な試験を受けます。超音波試験、磁気粒子検査、寸法確認により、完全な品質遵守が保証されます。材料証明書には、完全なトレーサビリティ文書と第三者検査報告書が含まれています。

🧪 Chemical Composition

| 元素 | 組成 (%) |

|---|---|

| 炭素 (C) | ≤ 0.030 |

| シリコン (Si) | ≤ 1.00 |

| マンガン (Mn) | ≤ 2.00 |

| リン (P) | ≤ 0.035 |

| 硫黄 (S) | ≤ 0.020 |

| クロム (Cr) | 21.0 - 23.0 |

| ニッケル (Ni) | 4.5 - 6.5 |

| モリブデン (Mo) | 2.5 - 3.5 |

| 窒素 (N) | 0.08 - 0.20 |

| 銅 (Cu) | ≤ 0.50 |

| タングステン (W) | ≤ 0.50 |

⚙️ Mechanical Properties

| 特性 | 値 |

|---|---|

| 引張強度 (Rm) | ≥ 640 MPa |

| 降伏強度 0.2% (Rp0.2) | ≥ 450 MPa |

| 伸び (A5) | ≥ 25% |

| 硬度 (HRC) | ≤ 31 |

| 硬度 (HB) | ≤ 290 |

| 衝撃エネルギー (KV) -40°Cで | ≥ 60 J |

| ヤング率 | 200 GPa |

| 疲労限界 (107 サイクル) | 320 MPa |

| フェライト含有量 | 40-60% |

| PREN値 | ≥ 35 |

🔬 Physical Properties

| 特性 | 値 |

|---|---|

| 密度 | 7.8 g/cm³ |

| 融点 | 1350-1400°C |

| 熱伝導率 (20°C) | 14 W/m·K |

| 熱伝導率 (100°C) | 16 W/m·K |

| 熱膨張 (20-100°C) | 13×10-6/K |

| 熱膨張 (20-300°C) | 14×10-6/K |

| 比熱容量 | 500 J/kg·K |

| 電気抵抗率 (20°C) | 0.85 µΩ·m |

| 磁気透過率 | 1.5-2.0 |

| ポアソン比 | 0.28 |

📏 Product Specifications

| 仕様 | 利用可能なオプション |

|---|---|

| 製品形状 | 丸棒、平棒、板、シート、チューブ、パイプ、鍛造品、フランジ |

| 丸棒直径 | 6mm - 300mm |

| 平棒寸法 | 10×3mm - 200×50mm |

| 板厚 | 3mm - 100mm |

| シート厚 | 0.5mm - 6mm |

| チューブ外径 | 6mm - 219mm |

| 規格 | EN 10088, ASTM A240, A479, A790, JIS G4305, GB/T 1220 |

| 表面仕上げ | 熱間圧延、冷間圧延、2B、BA、No.4、ヘアライン、ミラー |

| 公差 | ±0.1mmから±0.5mm(形状とサイズに依存) |

| 長さ | 標準: 6m、カスタム: 最大12m |

あなたのプロジェクトの成功を共に創りましょう

プロフェッショナルチーム、プレミアム製品、完全なサービス - あなたのプロジェクトの成功は私たちの使命です

Our Advantages in Processing 1.4462

高度な真空溶融技術

MetalZenithは、最先端の真空誘導溶解(VIM)および電気スラグ再溶解(ESR)プロセスを採用して、EN 1.4462の製造において卓越した化学的均一性と純度を実現しています。私たちの制御された雰囲気での溶解は、包含物を排除し、バランスの取れたオーステナイト-フェライト相を持つ最適な二相微細構造を確保します。

包括的な品質管理システム

私たちの統合品質管理システムは、リアルタイムプロセス監視、自動化された化学分析、および高度な冶金試験を特徴としています。EN 1.4462の各熱処理は、PREN計算、フェライト含有量測定、腐食抵抗評価を含む厳格な試験を受けて、一貫した性能を保証します。

グローバルサプライチェーンとカスタマイズ

MetalZenithは、世界中に戦略的な在庫拠点を維持し、EN 1.4462のための広範なカスタマイズ機能を提供しています。精密加工から特殊熱処理まで、特定のプロジェクト要件や厳しい納期に対応するために、柔軟な納品スケジュールでカスタマイズされたソリューションを提供します。

あなたの信頼できる 鋼

製造パートナー

クイックお問い合わせ

私たちが提供する業界

主要産業向けのプロフェッショナルな鋼ソリューション

資格と認証