20年の経験 | 1000以上のブランドパートナー | 完全なカスタマイズ

私たちは20年の業界経験があり、1,000以上のブランドと提携し、あらゆるカスタマイズニーズをサポートしています。

Technical Specifications

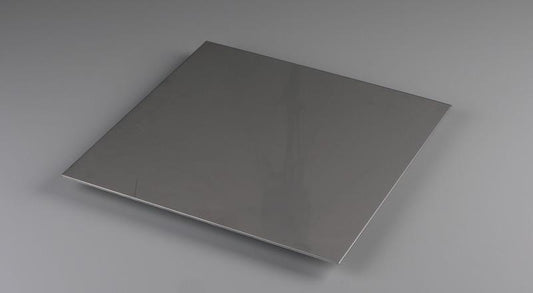

Product Overview

AR400 耐摩耗鋼板は、優れた耐摩耗性を必要とする用途向けに特別に設計された高強度の焼入れおよび焼き戻し合金鋼板です。このプレミアムグレードの鋼は、優れた硬度と靭性の組み合わせを提供し、重工業用途に最適です。

主な特徴:

- 400 HBの典型的な硬度を持つ優れた耐摩耗性

- 優れた衝撃抵抗と靭性

- 適切な手順による良好な溶接性

- 一貫した厚さ方向の特性

- 摩耗環境での延長されたサービス寿命

製造プロセス:制御された焼入れおよび焼き戻しプロセスを通じて製造され、板厚全体にわたって均一な微細構造と一貫した機械的特性を確保しています。

用途:鉱業機器、建設機械、材料搬送機器、摩耗プレート、シュート、ホッパー、トラックベッド、ブルドーザーのブレード、掘削機のバケット、およびその他の高摩耗産業用途。

🧪 Chemical Composition

Chemical Composition:

| 元素 | 最小 % | 最大 % | 典型 % | ASTM A514 要求 |

|---|---|---|---|---|

| 炭素 (C) | 0.15 | 0.25 | 0.20 | 0.15-0.25 |

| マンガン (Mn) | 0.80 | 1.50 | 1.20 | 0.80-1.50 |

| シリコン (Si) | 0.15 | 0.80 | 0.45 | 0.15-0.80 |

| リン (P) | - | 0.025 | 0.015 | ≤ 0.025 |

| 硫黄 (S) | - | 0.010 | 0.005 | ≤ 0.010 |

| クロム (Cr) | 0.40 | 1.20 | 0.80 | 0.40-1.20 |

| ニッケル (Ni) | 0.30 | 1.00 | 0.65 | 0.30-1.00 |

| モリブデン (Mo) | 0.15 | 0.60 | 0.35 | 0.15-0.60 |

| ホウ素 (B) | 0.0005 | 0.006 | 0.003 | 0.0005-0.006 |

| 鉄 (Fe) | バランス | バランス | 96.4 | バランス |

⚙️ Mechanical Properties

機械的特性:

| 特性 | ASTM 要件 | 典型値 | 試験方法 | 温度 |

|---|---|---|---|---|

| 引張強度 | 1180 MPa 最小 | 1250 MPa | ASTM A370 | 常温 |

| 降伏強度 (0.2%) | 1030 MPa 最小 | 1100 MPa | ASTM A370 | 常温 |

| 伸び | 12% 最小 | 15% | ASTM A370 | 常温 |

| 硬度 (ブリネル) | 360-440 HB | 400 HB | ASTM E10 | 常温 |

| 硬度 (ロックウェル C) | 38-46 HRC | 42 HRC | ASTM E18 | 常温 |

| 弾性係数 | - | 210 GPa | ASTM E111 | 常温 |

| 衝撃エネルギー (シャルピー V) | 40 J 最小 | 55 J | ASTM E23 | -40°C |

🔬 Physical Properties

物理特性:

| 特性 | 値 | 単位 | 温度 | 試験基準 |

|---|---|---|---|---|

| 密度 | 7.85 | g/cm3 | 20°C | ASTM B311 |

| 融点 | 1480-1520 | °C | - | DSC分析 |

| 熱伝導率 | 42 | W/m·K | 100°C | ASTM E1461 |

| 比熱 | 460 | J/kg·K | 0-100°C | ASTM C351 |

| 線膨張 | 12.5 | μm/m·K | 0-100°C | ASTM E228 |

| 電気抵抗率 | 180 | n|°¤m | 20°C | ASTM B193 |

| 磁気透過率 | 強磁性 | - | 室温 | ASTM A342 |

| キュリー温度 | 770 | °C | - | 磁気分析 |

📏 Product Specifications

Product Specifications:

| 仕様 | 利用可能範囲 | 標準サイズ | カスタム利用可能 | 公差 |

|---|---|---|---|---|

| 厚さ | 6mm - 150mm | 10-50mm | はい | ±0.5mm |

| 幅 | 1000mm - 3000mm | 1500-2000mm | はい | ±5mm |

| 長さ | 2000mm - 12000mm | 6000mm | はい | +50mm/-0mm |

| 表面仕上げ | 熱間圧延、ショットブラスト | 熱間圧延 | はい | Ra ≤ 12.5μm |

| エッジ状態 | ミルエッジ、カットエッジ | ミルエッジ | 両方 | ASTM標準 |

| 平坦度 | ≤ 5mm/m | ≤ 3mm/m | はい | ASTM A6 |

| 規格適合 | ASTM A514、JIS G3128 | A514 | 複数 | 完全適合 |

| 熱処理 | 焼入れおよび焼戻し | Q&T | 標準 | 制御されたプロセス |

| 試験証明書 | ミルTC、EN 10204 3.1 | ミルTC | はい | 標準 |

| 包装 | バンドル、クレート、コンテナ | バンドル | カスタム | 輸出標準 |

あなたのプロジェクトの成功を共に創りましょう

プロフェッショナルチーム、プレミアム製品、完全なサービス - あなたのプロジェクトの成功は私たちの使命です

Our Advantages in Processing AR400 耐摩耗鋼板

優れた硬度制御

精密な製造プロセスにより、全体のプレート表面で360-440 BHNの一貫した硬度レベルが確保され、摩耗抵抗特性を最適化するために慎重に制御された熱処理と冷却サイクルを通じて達成されます。

高度な合金組成

特殊な高炭素合金の配合は、正確な冶金プロセスを通じて開発され、最適な化学組成を実現し、構造的完全性を維持しながら耐摩耗性を向上させます。

均匀板形成

最先端の圧延および成形プロセスにより、一貫して平坦な板が作成され、厳しい厚さ公差が確保され、要求の厳しい用途において均一な摩耗特性と延長されたサービス寿命が保証されます。

あなたの信頼できる 鋼

製造パートナー

20

年数の経験

鋼鉄製造および流通のリーディング

1000以上

ブランドパートナー

グローバル業界のリーダーに信頼されています

完全

カスタマイズ

すべてのプロジェクトに合わせたソリューション

50M+

配達されたトン数

高品質の鋼製品を世界中に

95%

クライアントの維持

長期的なパートナーシップの成功

ISO 9001

認証された品質

国際標準の遵守

20

年数の経験

鋼鉄製造および流通のリーディング

1000以上

ブランドパートナー

グローバル業界のリーダーに信頼されています

完全

カスタマイズ

すべてのプロジェクトに合わせたソリューション

50M+

配達されたトン数

高品質の鋼製品を世界中に

95%

クライアントの維持

長期的なパートナーシップの成功

ISO 9001

認証された品質

国際標準の遵守

お問い合わせ

クイックお問い合わせ

最小注文数量:3トン

私たちが提供する業界

主要産業向けのプロフェッショナルな鋼ソリューション

資格と認証