20 Years Experience | 1000+ Brand Partners | Full Customization

We have 20 years of industry experience, have partnered with over 1,000 brands, and support any customization needs.

Technical Specifications

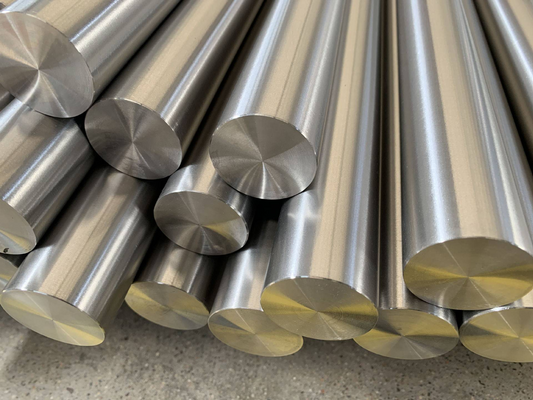

Product Overview

Metallurgical Characteristics

GB Q550 is a microalloyed high-strength low-alloy steel featuring a fine-grained ferrite-pearlite microstructure with precipitation strengthening from vanadium and niobium carbides. The controlled rolling process followed by accelerated cooling produces optimal grain refinement, resulting in excellent strength-toughness balance and superior weldability compared to conventional carbon steels.

Heat Treatment & Processing

MetalZenith manufactures GB Q550 using thermomechanical controlled processing (TMCP) with finishing temperatures between 850-950°C followed by accelerated cooling to 500-600°C. This process eliminates the need for post-rolling heat treatment while achieving superior mechanical properties. Stress relief annealing at 580-650°C may be applied for heavy sections to optimize residual stress distribution.

Manufacturing Process

Production begins with electric arc furnace steelmaking followed by ladle refining and continuous casting. The controlled rolling process utilizes computer-controlled rolling mills with precise temperature monitoring and deformation scheduling. Accelerated cooling systems ensure uniform cooling rates across the material cross-section, maintaining consistent mechanical properties throughout the product thickness.

Quality Standards & Certification

All GB Q550 products are manufactured in accordance with GB/T 1591 standards and undergo comprehensive quality control including chemical analysis by optical emission spectroscopy, mechanical testing per GB/T 228.1, Charpy impact testing per GB/T 229, and ultrasonic inspection per GB/T 2970. MetalZenith maintains ISO 9001:2015, ISO 14001:2015, and OHSAS 18001 certifications with full traceability documentation and third-party inspection capabilities.

🧪 Chemical Composition

| Element | Content (%) |

|---|---|

| Carbon (C) | ≤ 0.18 |

| Manganese (Mn) | 1.00-1.70 |

| Silicon (Si) | 0.15-0.55 |

| Phosphorus (P) | ≤ 0.025 |

| Sulfur (S) | ≤ 0.015 |

| Chromium (Cr) | ≤ 0.80 |

| Nickel (Ni) | ≤ 2.00 |

| Molybdenum (Mo) | ≤ 0.30 |

| Vanadium (V) | 0.02-0.15 |

| Niobium (Nb) | 0.015-0.060 |

| Titanium (Ti) | 0.006-0.030 |

| Aluminum (Al) | ≥ 0.015 |

⚙️ Mechanical Properties

| Property | Value |

|---|---|

| Yield Strength (ReH) | ≥ 550 MPa |

| Tensile Strength (Rm) | 600-780 MPa |

| Elongation (A50) | ≥ 17% |

| Impact Energy (KV2) at 0°C | ≥ 34 J |

| Impact Energy (KV2) at -20°C | ≥ 27 J |

| Brinell Hardness (HB) | 180-250 |

| Young's Modulus | 210 GPa |

| Poisson's Ratio | 0.30 |

| Fatigue Limit (107 cycles) | 280 MPa |

| Reduction of Area | ≥ 50% |

🔬 Physical Properties

| Property | Value |

|---|---|

| Density | 7.85 g/cm³ |

| Melting Point | 1510°C |

| Thermal Conductivity (20°C) | 54 W/m·K |

| Thermal Expansion Coefficient (20-100°C) | 12×10-6/K |

| Specific Heat Capacity | 500 J/kg·K |

| Electrical Resistivity (20°C) | 0.16 µΩ·m |

| Magnetic Permeability | Ferromagnetic |

| Curie Temperature | 770°C |

| Thermal Diffusivity | 13.7 mm²/s |

📏 Product Specifications

| Specification | Available Options |

|---|---|

| Product Forms | Plates, Sheets, Coils, Bars, Profiles |

| Thickness Range | 3-100 mm (Plates), 1.5-12 mm (Sheets) |

| Width Range | 1000-3200 mm |

| Length Range | 3000-18000 mm |

| Standards | GB/T 1591, GB/T 3274, GB/T 11263 |

| Surface Finish | Hot Rolled, Normalized, Pickled & Oiled |

| Edge Condition | Mill Edge, Slit Edge, Sheared Edge |

| Thickness Tolerance | ±0.3 mm (t≤20mm), ±0.5 mm (t>20mm) |

| Width Tolerance | ±5 mm |

| Length Tolerance | ±10 mm |

| Flatness | ≤5 mm/m |

Let Us Create Success for Your Project

Professional Team, Premium Products, Complete Service - Your Project Success is Our Mission

Our Advantages in Processing GB Q550

Advanced Thermomechanical Processing

MetalZenith employs cutting-edge controlled rolling and accelerated cooling technology to achieve optimal microstructure refinement in GB Q550 steel. Our precise temperature control and rolling parameters ensure uniform grain structure and superior mechanical properties throughout the material thickness.

Comprehensive Quality Control System

Our integrated quality management system includes real-time chemical composition monitoring, automated mechanical testing, ultrasonic flaw detection, and dimensional verification. Every coil and plate receives full inspection with certified test reports meeting international standards.

Flexible Production & Global Supply

MetalZenith offers extensive customization capabilities for GB Q550 including various thickness ranges, surface treatments, and cut-to-length services. Our global logistics network ensures reliable delivery worldwide with comprehensive technical support and engineering consultation services.

YOUR TRUSTED STEEL

MANUFACTURING PARTNER

Quick Inquiry

Industries We Serve

Professional steel solutions across major industries

Qualifications & Certifications