20 Jahre Erfahrung | 1000+ Markenpartner | Vollständige Anpassung

Wir haben 20 Jahre Branchenerfahrung, haben mit über 1.000 Marken zusammengearbeitet und unterstützen alle Anpassungsbedürfnisse.

Technical Specifications

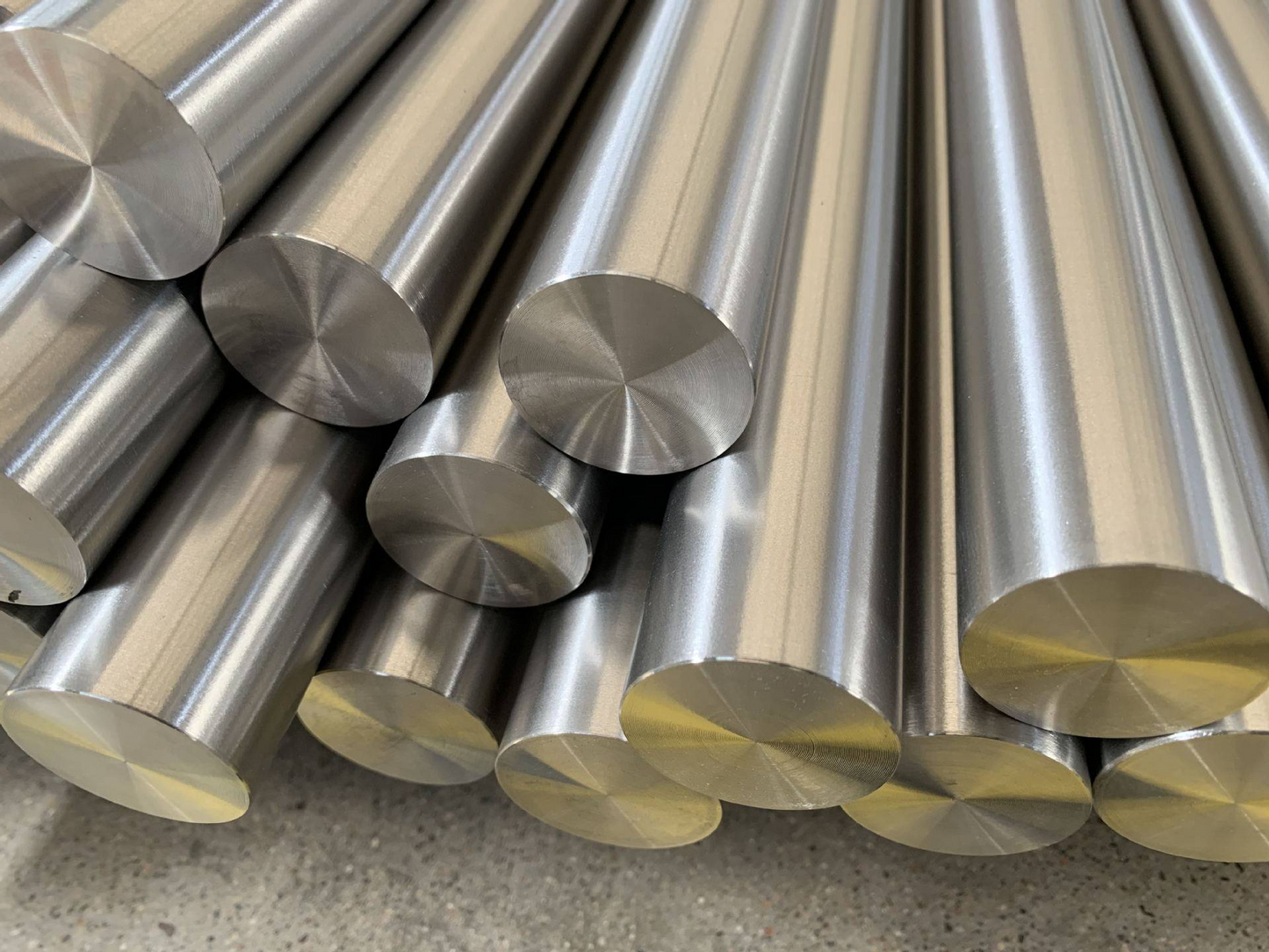

Product Overview

Metallurgische Eigenschaften

HSLA 450 weist eine feinkörnige Ferrit-Perlit-Mikrostruktur mit kontrollierter Ausfällung von Mikrolegierungselementen wie Niob, Vanadium und Titan auf. Die thermomechanische Verarbeitung schafft eine verfeinerte Kornstruktur mit Ausfällungsstärkung, die ein überlegenes Verhältnis von Festigkeit zu Gewicht im Vergleich zu herkömmlichen Kohlenstoffstählen bietet. Die optimierte Chemie sorgt für hervorragende Schweißbarkeit mit niedrigem Kohlenstoffäquivalent (CE ≤ 0.45) und guter Formbarkeit für komplexe Geometrien.

Wärmebehandlung & Verarbeitung

Das HSLA 450 von MetalZenith wird durch kontrolliertes Walzen bei Temperaturen zwischen 850-950°C hergestellt, gefolgt von beschleunigter Abkühlung, um eine optimale mikrostrukturelle Entwicklung zu erreichen. Der Stahl wird typischerweise im gewalzten Zustand mit normalisierten Eigenschaften geliefert. Eine Spannungsarmglühung bei 580-620°C kann angewendet werden, um die dimensionsstabilität zu verbessern. Das Material zeigt hervorragende Bearbeitbarkeit und kann leicht mit herkömmlichen Techniken wie Biegen, Stanzen und Tiefziehen geformt werden.

Exzellenz im Herstellungsprozess

Unser integriertes Stahlproduktionswerk nutzt die Technologie des Lichtbogenofens mit sekundärer Raffination durch Pfannenmetallurgie und Vakuumentgasung. Die kontinuierliche Gießung gewährleistet eine homogene chemische Zusammensetzung und minimale Segregation. Der Warmwalzprozess integriert computersteuerbare Kühlsysteme, um präzise mechanische Eigenschaften zu erreichen. Fortschrittliche Prozesskontrollsysteme überwachen Temperatur, Reduktionsverhältnisse und Kühlraten, um eine konsistente Qualität während der Produktion sicherzustellen.

Qualitätsstandards & Prüfung

Die Produktion von HSLA 450 bei MetalZenith entspricht internationalen Qualitätsstandards, einschließlich ISO 9001:2015, ASTM A572 und EN 10025-4. Umfassende Prüfprotokolle umfassen chemische Analysen mittels optischer Emissionsspektrometrie, mechanische Prüfungen gemäß ASTM E8/E8M, Charpy-Schlagprüfungen gemäß ASTM E23 und Ultraschalluntersuchungen gemäß ASTM A578. Die statistische Prozesskontrolle gewährleistet eine Konformität von 99,7 % mit den Spezifikationen, wobei eine vollständige Materialverfolgbarkeit und Zertifizierungsdokumentation mit jeder Lieferung bereitgestellt wird.

🧪 Chemical Composition

| Element | Zusammensetzung (%) |

|---|---|

| Kohlenstoff (C) | ≤ 0.18 |

| Mangan (Mn) | 0.80 - 1.60 |

| Silizium (Si) | 0.15 - 0.50 |

| Phosphor (P) | ≤ 0.025 |

| Schwefel (S) | ≤ 0.015 |

| Chrom (Cr) | 0.30 - 0.80 |

| Nickel (Ni) | 0.30 - 0.80 |

| Molybdän (Mo) | 0.15 - 0.30 |

| Kupfer (Cu) | 0.20 - 0.50 |

| Aluminium (Al) | 0.020 - 0.060 |

| Niob (Nb) | 0.015 - 0.060 |

| Vanadium (V) | 0.02 - 0.10 |

| Titan (Ti) | 0.006 - 0.025 |

| Stickstoff (N) | ≤ 0.015 |

⚙️ Mechanical Properties

| Eigenschaft | Wert |

|---|---|

| Streckgrenze (Rp0.2) | ≥ 450 MPa |

| Zugfestigkeit (Rm) | 520 - 670 MPa |

| Dehnung (A80) | ≥ 19% |

| Dehnung (A5) | ≥ 17% |

| Brinell-Härte (HB) | 150 - 200 |

| Vickers-Härte (HV) | 160 - 220 |

| Schlagenergie (KV) bei 20°C | ≥ 40 J |

| Schlagenergie (KV) bei -20°C | ≥ 27 J |

| Schlagenergie (KV) bei -40°C | ≥ 20 J |

| Youngs Modul | 210 GPa |

| Schubmodul | 80 GPa |

| Poisson-Zahl | 0.30 |

| Ermüdungsgrenze (10^7 Zyklen) | 225 MPa |

🔬 Physical Properties

| Eigenschaft | Wert |

|---|---|

| Dichte | 7.85 g/cm³ |

| Schmelzpunkt | 1510°C |

| Wärmeleitfähigkeit (20°C) | 52 W/m·K |

| Wärmeleitfähigkeit (100°C) | 48 W/m·K |

| Wärmeausdehnung (20-100°C) | 12.5×10-6/K |

| Wärmeausdehnung (20-200°C) | 13.0×10-6/K |

| Spezifische Wärmekapazität | 460 J/kg·K |

| Elektrische Widerstandsfähigkeit (20°C) | 0.18 µΩ·m |

| Magnetische Permeabilität | Ferromagnetisch |

| Curie-Temperatur | 770°C |

| Wärmediffusivität (20°C) | 14.4 mm²/s |

| Emissivität (oxidierte Oberfläche) | 0.79 |

📏 Product Specifications

| Spezifikation | Verfügbare Optionen |

|---|---|

| Produktformen | Warmgewalzte Platten, Kaltgewalzte Bleche, Coils, Streifen, Stangen, Strukturprofile |

| Plattendicke | 3 - 100 mm |

| Blechdicke | 0.5 - 6.0 mm |

| Breitenbereich | 600 - 2500 mm |

| Längenbereich | 2000 - 12000 mm |

| Coil-Gewicht | Bis zu 35 Tonnen |

| Normen-Konformität | ASTM A572, EN 10025-4, JIS G3106, GB/T 1591 |

| Oberflächenfinish | Warmgewalzt, Entzundert, Kaltgewalzt, Verzinkt, Lackiert |

| Kantenzustand | Walzkante, Schnittkante, Beschnittene Kante |

| Planheits-Toleranz | ≤ 5 mm/m |

| Dicken-Toleranz | ±0.05 - ±0.3 mm (je nach Dicke) |

| Breiten-Toleranz | ±3 - ±10 mm (je nach Breite) |

| Längen-Toleranz | +10/-0 mm |

Lassen Sie uns Erfolg für Ihr Projekt schaffen

Professionelles Team, Premium-Produkte, Vollständiger Service - Ihr Projekterfolg ist unsere Mission

Our Advantages in Processing HSLA 450

Fortgeschrittene thermomechanische Verarbeitung

MetalZenith setzt modernste kontrollierte Walz- und beschleunigte Kühltechnologien ein, um eine präzise mikrostrukturelle Kontrolle in HSLA 450 zu erreichen. Unsere fortschrittlichen Prozessparameter gewährleisten eine gleichmäßige Kornverfeinerung und optimale Ausscheidungshärtung, die konsistente mechanische Eigenschaften und überlegene Zähigkeit über alle Produktabmessungen hinweg liefern.

Umfassendes Qualitätskontrollsystem

Unser integriertes Qualitätsmanagementsystem verfügt über die Überwachung der chemischen Zusammensetzung in Echtzeit, automatisierte mechanische Prüfungen und fortschrittliche metallurgische Analysen. Das Labor von MetalZenith ist mit modernsten Spektrometern, universellen Prüfmaschinen und Einrichtungen für Elektronenmikroskopie ausgestattet, um sicherzustellen, dass HSLA 450 die strengsten Spezifikationen erfüllt.

Maßgeschneiderte Ingenieurleistungen & Globale Versorgung

MetalZenith bietet maßgeschneiderte HSLA 450-Lösungen mit individuellen chemischen Zusammensetzungen, mechanischen Eigenschaften und Produktformen, um spezifische Anwendungsanforderungen zu erfüllen. Unser globales Vertriebsnetz und strategisches Bestandsmanagement gewährleisten eine zuverlässige Unterstützung der Lieferkette mit Just-in-Time-Lieferfähigkeiten weltweit.

IHR VERTRAUENwürdiger STAHL

HERSTELLUNGSPARTNER

Schnellanfrage

Branchen, die wir bedienen

Professionelle Stahl-Lösungen in wichtigen Branchen

Qualifikationen & Zertifizierungen