20 Jahre Erfahrung | 1000+ Markenpartner | Vollständige Anpassung

Wir haben 20 Jahre Branchenerfahrung, haben mit über 1.000 Marken zusammengearbeitet und unterstützen alle Anpassungsbedürfnisse.

Technical Specifications

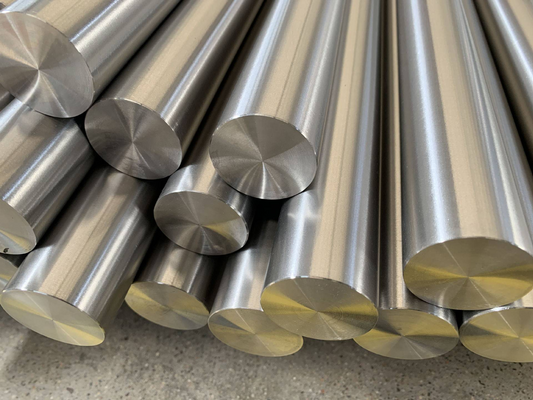

Product Overview

Metallurgische Eigenschaften

GB Q690 ist ein niedriglegierter, hochfester Baustahl mit einer feinkörnigen Mikrostruktur, die durch kontrolliertes Walzen und beschleunigte Abkühlprozesse erreicht wird. Der Stahl weist eine überwiegend ferritisch-bainitische Mikrostruktur mit dispergierten Karbidniederschlägen auf, die eine hervorragende Kombination aus Festigkeit, Zähigkeit und Schweißbarkeit bietet. Die kontrollierte Zugabe von Mikrolegierungselementen wie Vanadium, Niobium und Titan ermöglicht die Ausscheidungsstärkung und Kornverfeinerung.

Wärmebehandlung & Verarbeitung

MetalZenith verwendet fortschrittliche thermomechanische kontrollierte Verarbeitung (TMCP) als primären Produktionsweg für GB Q690 Stahl. Der Prozess umfasst kontrolliertes Walzen bei Temperaturen zwischen 850-950°C, gefolgt von beschleunigter Abkühlung, um optimale mechanische Eigenschaften zu erreichen. Alternative Wärmebehandlungsoptionen umfassen Normalisieren bei 900-950°C oder Härten und Anlassen mit Austenitisierung bei 900-930°C, Härten in Wasser oder Öl und Anlassen bei 580-650°C, abhängig von den spezifischen Anwendungsanforderungen.

Exzellenz im Herstellungsprozess

Unser Herstellungsprozess beginnt mit der sorgfältigen Auswahl der Rohstoffe und einer präzisen Chargeberechnung, um die Zielchemie zu erreichen. Der Stahl wird in Lichtbogenöfen geschmolzen, gefolgt von einer sekundären Raffination durch Pfannenofen und Vakuumentgasung, um einen niedrigen Einschlussgehalt und optimale Sauberkeit sicherzustellen. Die kontinuierliche Gießung produziert hochwertige Brammen und Platten, die anschließend durch unsere hochmodernen Walzwerke verarbeitet werden, die mit fortschrittlichen Prozesskontrollsystemen für präzise Temperatur- und Verformungskontrolle ausgestattet sind.

Qualitätsstandards & Zertifizierungen

Der von MetalZenith hergestellte GB Q690 Stahl entspricht dem Standard GB/T 1591-2018 und gleichwertigen internationalen Spezifikationen, einschließlich EN 10025-6 S690QL und ASTM A514. Unser Qualitätsmanagementsystem ist nach ISO 9001:2015 zertifiziert, und wir halten zusätzliche Zertifizierungen, einschließlich ISO 14001 für Umweltmanagement und OHSAS 18001 für Arbeitsschutz und Sicherheit. Jede Produktionscharge unterliegt umfassenden Tests, einschließlich chemischer Analyse durch optische Emissionsspektroskopie, Verifizierung der mechanischen Eigenschaften, Ultraschallprüfung auf innere Festigkeit und dimensionaler Inspektion.

Schweiß- & Fertigungsrichtlinien

GB Q690 Stahl weist eine hervorragende Schweißbarkeit auf, wenn die richtigen Verfahren befolgt werden. Eine Vorwärmung auf 100-150°C wird für Abschnitte empfohlen, die dicker als 25 mm sind. Niedrigwasserstoff-Schweißzusätze sollten verwendet werden, wobei die Interpass-Temperaturen unter 250°C gehalten werden sollten. Eine Nachbehandlung nach dem Schweißen kann für die Spannungsfreisetzung in kritischen Anwendungen vorteilhaft sein. Der Stahl kann leicht geformt, bearbeitet und mit herkömmlichen Methoden gefertigt werden, obwohl aufgrund seines hohen Festigkeitsniveaus höhere Schnittkräfte erforderlich sein können.

🧪 Chemical Composition

| Element | Inhalt (%) | Zweck |

|---|---|---|

| Kohlenstoff (C) | ≤ 0.18 | Festigkeit und Härte |

| Mangan (Mn) | 1.00-1.70 | Festigkeit und Härtbarkeit |

| Silizium (Si) | 0.15-0.60 | Entgasung und Festigkeit |

| Phosphor (P) | ≤ 0.025 | Kontrollierte Verunreinigung |

| Schwefel (S) | ≤ 0.015 | Kontrollierte Verunreinigung |

| Chrom (Cr) | 0.30-1.50 | Härtbarkeit und Festigkeit |

| Nickel (Ni) | 0.30-2.00 | Zähigkeit und Festigkeit |

| Molybdän (Mo) | 0.15-0.70 | Härtbarkeit und Kriechbeständigkeit |

| Vanadium (V) | 0.02-0.12 | Kornglättung |

| Niob (Nb) | 0.015-0.060 | Ausscheidungsstärkung |

| Titan (Ti) | 0.006-0.050 | Kornglättung |

| Aluminium (Al) | ≥ 0.015 | Entgasung und Kornglättung |

⚙️ Mechanical Properties

| Eigenschaft | Wert | Prüfstandard |

|---|---|---|

| Streckgrenze (ReL) | ≥ 690 MPa | GB/T 228.1 |

| Zugfestigkeit (Rm) | 770-940 MPa | GB/T 228.1 |

| Dehnung (A50) | ≥ 14% | GB/T 228.1 |

| Schlagenergie (KV2) bei 20°C | ≥ 47 J | GB/T 229 |

| Schlagenergie (KV2) bei -20°C | ≥ 34 J | GB/T 229 |

| Schlagenergie (KV2) bei -40°C | ≥ 27 J | GB/T 229 |

| Brinell-Härte (HBW) | 230-280 | GB/T 231.1 |

| Youngs Modul | 210 GPa | GB/T 22315 |

| Poisson-Zahl | 0.30 | GB/T 22315 |

| Ermüdungsgrenze (10&sup7; Zyklen) | 350 MPa | GB/T 4337 |

| Bruchzähigkeit (KIC) | 120 MPa·m1/2 | GB/T 4161 |

| Kaltbiegeprüfung (180°) | 3t (t = Dicke) | GB/T 232 |

🔬 Physical Properties

| Eigenschaft | Wert | Temperatur/Bedingungen |

|---|---|---|

| Dichte | 7.85 g/cm³ | 20°C |

| Schmelzpunkt | 1510°C | Solidustemperatur |

| Wärmeleitfähigkeit | 54 W/m·K | 20°C |

| Wärmeausdehnungskoeffizient | 12×10-6/K | 20-100°C |

| Spezifische Wärmekapazität | 500 J/kg·K | 20°C |

| Elektrische Widerstandsfähigkeit | 0.16 µΩ·m | 20°C |

| Magnetische Permeabilität | Ferromagnetisch | Raumtemperatur |

| Curie-Temperatur | 770°C | Magnetische Übergang |

| Wärmediffusivität | 13.7×10-6 m²/s | 20°C |

| Emissivität | 0.85 | Oxidierte Oberfläche |

| Schallgeschwindigkeit (Längs) | 5900 m/s | 20°C |

| Schallgeschwindigkeit (Querschnitt) | 3200 m/s | 20°C |

📏 Product Specifications

| Spezifikation | Verfügbare Optionen | Standards |

|---|---|---|

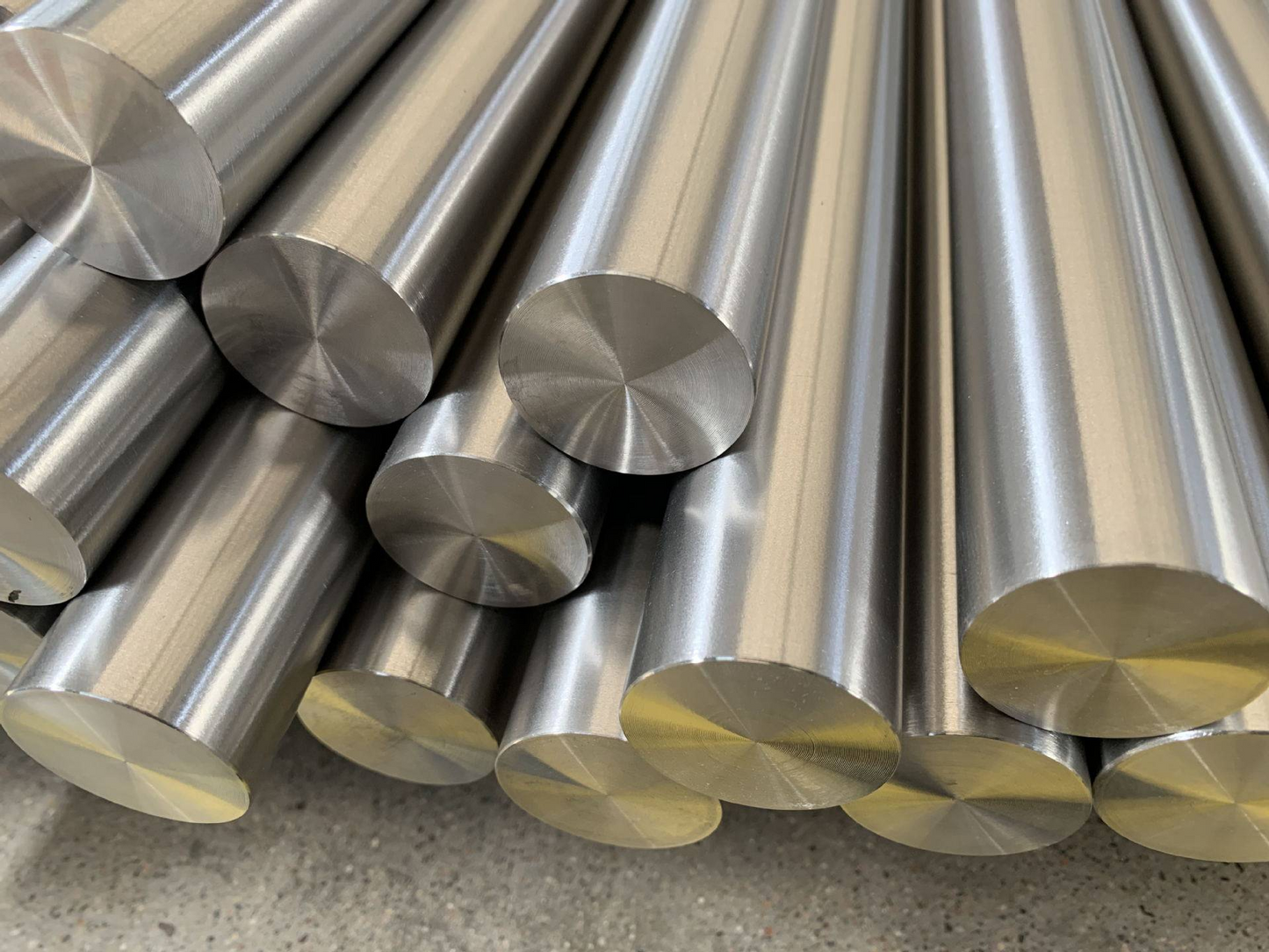

| Produktformen | Platten, Bleche, Stangen, Rohre, Schmiedeteile, Sonderformen | GB/T 1591, GB/T 3274 |

| Plattendicke | 8-100 mm | GB/T 3274 |

| Plattenbreite | 1500-4200 mm | GB/T 3274 |

| Plattenlänge | 6000-18000 mm | GB/T 3274 |

| Stangendurchmesser | 16-300 mm | GB/T 702 |

| Rohraußendurchmesser | 25-600 mm | GB/T 8162 |

| Rohrwandstärke | 3-50 mm | GB/T 8162 |

| Oberflächenfinish | Warmgewalzt, Normalisiert, Vergütet, Strahlgebläßt, Beizt | GB/T 1591 |

| Maßtoleranz | Klasse A, B, C gemäß GB-Standards | GB/T 3274, GB/T 702 |

| Planheitstoleranz | ≤ 5 mm/m | GB/T 3274 |

| Kantenzustand | Millkante, Beschnittene Kante, Geschnittene Kante | GB/T 3274 |

| Lieferzustand | TMCP, N (Normalisiert), Q+T (Vergütet) | GB/T 1591 |

Lassen Sie uns Erfolg für Ihr Projekt schaffen

Professionelles Team, Premium-Produkte, Vollständiger Service - Ihr Projekterfolg ist unsere Mission

Our Advantages in Processing GB Q690

Fortgeschrittene TMCP-Technologie

MetalZenith setzt modernste thermomechanische Kontrollverarbeitung (TMCP) Technologie mit präziser Temperaturkontrolle und optimierten Walzplänen ein, um eine überlegene Kornverfeinerung und verbesserte mechanische Eigenschaften in der Produktion von GB Q690 Stahl zu erreichen.

Umfassende Qualitätskontrolle

Unser integriertes Qualitätsmanagementsystem verfügt über eine Echtzeitüberwachung der chemischen Zusammensetzung, automatisierte mechanische Prüfungen und fortschrittliche zerstörungsfreie Prüfgeräte, um sicherzustellen, dass jede Charge von GB Q690-Stahl die höchsten Qualitätsstandards mit vollständiger Rückverfolgbarkeit erfüllt.

Flexible Anpassungsmöglichkeiten

MetalZenith bietet umfangreiche Anpassungsoptionen für GB Q690 Stahl, einschließlich verschiedener Produktformen, Abmessungen, Oberflächenbehandlungen und speziellen Verarbeitungsanforderungen, unterstützt durch unser globales Lieferkettennetzwerk und technische Ingenieurdienstleistungen.

IHR VERTRAUENwürdiger STAHL

HERSTELLUNGSPARTNER

Schnellanfrage

Branchen, die wir bedienen

Professionelle Stahl-Lösungen in wichtigen Branchen

Qualifikationen & Zertifizierungen