20 Jahre Erfahrung | 1000+ Markenpartner | Vollständige Anpassung

Wir haben 20 Jahre Branchenerfahrung, haben mit über 1.000 Marken zusammengearbeitet und unterstützen alle Anpassungsbedürfnisse.

Technical Specifications

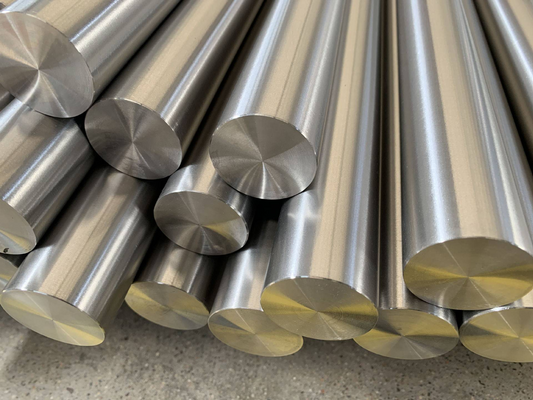

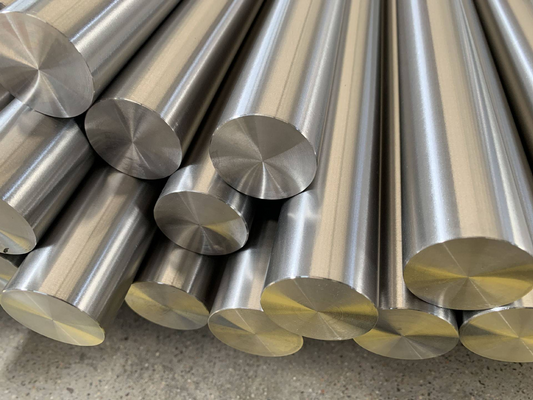

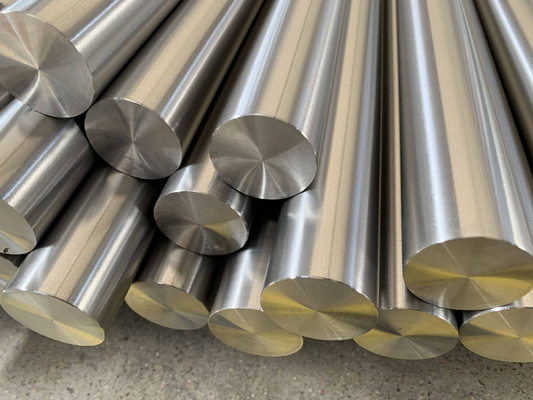

Product Overview

Metallurgische Eigenschaften

HSLA 50 weist eine feinkörnige ferritisch-perlitische Mikrostruktur mit kontrollierter Ausfällung von Mikrolegierungs-Karbid und -Nitrid auf. Die strategische Zugabe von Niob, Vanadium und Titan fördert die Kornverfeinerung durch Ausfällungsstärkung und Kornrandverankerung, was zu einer erhöhten Streckgrenze führt, während hervorragende Duktilität und Zähigkeit erhalten bleiben.

Wärmebehandlungsprozess

MetalZenith verwendet thermomechanisch kontrollierte Verarbeitung (TMCP) mit kontrollierten Walztemperaturen zwischen 850-950°C, gefolgt von beschleunigter Abkühlung. Dieser Prozess optimiert die Austenitbehandlung und fördert die Bildung feiner Ferritkörner mit gleichmäßiger Ausfällungsverteilung, wodurch ein überlegenes Verhältnis von Festigkeit zu Zähigkeit erreicht wird.

Fortschrittlicher Herstellungsprozess

Unser hochmodernes Produktionswerk nutzt computergesteuerte Walzwerke mit präziser Temperaturüberwachung und Kühlsystemen. Der Herstellungsprozess umfasst kontinuierliches Gießen, Behandlung im Wiedererwärmungsofen, Mehrfachwalzen unter Kontrolle und programmierte Abkühlung, um konsistente mechanische Eigenschaften und mikrostrukturelle Homogenität über die Materialdicke hinweg sicherzustellen.

Spezialisierte Qualitätsprüfung

MetalZenith führt umfassende Testprotokolle durch, die speziell für hochfeste Stähle entwickelt wurden, einschließlich Erichsen-Kuppeltests zur Beurteilung der Formbarkeit, kontrollierte thermische Schwere (CTS)-Tests zur Bewertung der Schweißbarkeit, Tests auf Wasserstoffversprödung (HIC) unter Verwendung der NACE TM0284-Standards und verzögerte Bruchtests unter anhaltenden Belastungsbedingungen, um die langfristige strukturelle Integrität sicherzustellen.

Anwendungsspezifische Überlegungen

Für Automobilanwendungen bietet HSLA 50 hervorragende Crashenergieabsorption und Gewichtseinsparungen. Im Bauwesen und Brückenbau bietet der Stahl überlegene Ermüdungsbeständigkeit und seismische Leistung. Für Druckbehälter und Hebezeuge zeigt das Material außergewöhnliche Beständigkeit gegen Spannungsrisskorrosion und erhält die strukturelle Integrität unter zyklischen Belastungsbedingungen, was es ideal für kritische Sicherheitsanwendungen macht.

🧪 Chemical Composition

| Element | Zusammensetzung (%) |

|---|---|

| Kohlenstoff (C) | ≤ 0.23 |

| Mangan (Mn) | 1.35 max |

| Silizium (Si) | 0.40 max |

| Phosphor (P) | ≤ 0.030 |

| Schwefel (S) | ≤ 0.030 |

| Niob (Nb) | 0.005 - 0.050 |

| Vanadium (V) | 0.01 - 0.15 |

| Titan (Ti) | 0.006 - 0.040 |

⚙️ Mechanical Properties

| Eigenschaft | Wert |

|---|---|

| Streckgrenze (MPa) | ≥ 345 |

| Zugfestigkeit (MPa) | 450 - 620 |

| Dehnung (%) | ≥ 18 |

| Schlagenergie bei 0°C (J) | ≥ 27 |

| Ermüdungsfestigkeit (MPa) | 160 - 180 |

| Härte (HB) | 140 - 190 |

🔬 Physical Properties

| Eigenschaft | Wert |

|---|---|

| Dichte (g/cm3) | 7.85 |

| Schmelzpunkt (°C) | 1510 - 1540 |

| Wärmeleitfähigkeit (W/m·K) | 49.8 |

| Wärmeausdehnung (×10??/K) | 11.7 |

| Elastizitätsmodul (GPa) | 200 |

| Poisson-Zahl | 0.27 - 0.30 |

📏 Product Specifications

| Spezifikation | Details |

|---|---|

| Verfügbare Formen | Platten, Bleche, Coils, Stangen, Strukturformen |

| Dickenbereich | 1,5 - 100mm |

| Breitenbereich | 1000 - 3200mm |

| Längenbereich | 6000 - 15000mm |

| Einhaltung von Standards | ASTM A572 Grad 50, ASTM A709 Grad 50 |

| Wärmebehandlungszustand | Warmgewalzt, TMCP, Normalisiert |

| Oberflächenfinish | Walzhaut, Entzundert, Strahlgebläßt |

Lassen Sie uns Erfolg für Ihr Projekt schaffen

Professionelles Team, Premium-Produkte, Vollständiger Service - Ihr Projekterfolg ist unsere Mission

Our Advantages in Processing HSLA 50 Stahl

Fortgeschrittene thermomechanische Verarbeitung

MetalZenith setzt präzise gesteuerte thermomechanische Bearbeitung mit optimierten Walztemperaturen und Abkühlraten ein, um eine feinkörnige Mikrostruktur und eine verbesserte Ausscheidungsstärkung zu erreichen. Unsere fortschrittliche TMCP-Technologie gewährleistet eine überlegene Streckgrenze und Ermüdungsbeständigkeit, während sie eine hervorragende Formbarkeit für komplexe Automobil- und Struktur-Anwendungen beibehält.

Umfassende Hochfestigkeitsprüfung

MetalZenith führt spezialisierte Testprotokolle für hochfeste Stähle durch, einschließlich fortschrittlicher Formbarkeitstests (Erichsen-Kuppeltest, Biegetests), Schweißbarkeitseinschätzungen (HAZ-Härte, Rissanfälligkeit), Bewertung der Widerstandsfähigkeit gegen wasserstoffinduzierte Rissbildung und Tests auf verzögerte Bruchbildung. Unsere umfassende Qualitätssicherung gewährleistet optimale Leistung in anspruchsvollen strukturellen Anwendungen.

Maßgeschneiderte Ingenieurlösungen

MetalZenith bietet maßgeschneiderte Verarbeitungslösungen, einschließlich individueller Wärmebehandlungspläne, präziser Schneid- und Formdienstleistungen sowie technischer Beratung für Anwendungen mit hochfestem Stahl. Unser Ingenieurteam bietet umfassende Unterstützung für die Gewichtsreduzierung im Automobilbau, die strukturelle Optimierung und die anwendungsspezifische Eigenschaftsverbesserung, um die genauen Projektanforderungen zu erfüllen.

IHR VERTRAUENwürdiger STAHL

HERSTELLUNGSPARTNER

Schnellanfrage

Branchen, die wir bedienen

Professionelle Stahl-Lösungen in wichtigen Branchen

Qualifikationen & Zertifizierungen