20 Jahre Erfahrung | 1000+ Markenpartner | Vollständige Anpassung

Wir haben 20 Jahre Branchenerfahrung, haben mit über 1.000 Marken zusammengearbeitet und unterstützen alle Anpassungsbedürfnisse.

Technical Specifications

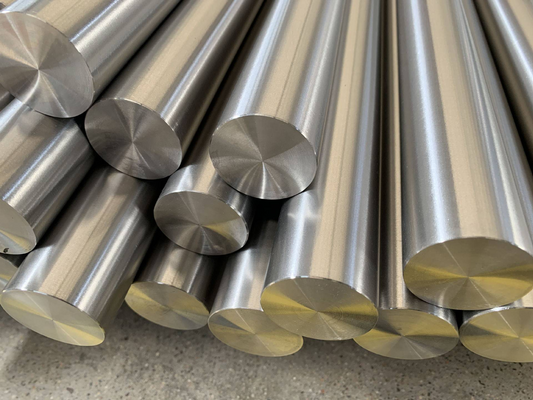

Product Overview

Metallurgische Eigenschaften

ASTM A572 Grade 50 ist ein hochfester, niedriglegierter (HSLA) Baustahl, der seine überlegenen mechanischen Eigenschaften durch kontrolliertes Walzen und Mikrolegierungstechniken erreicht. Der Stahl weist eine feinkörnige Ferrit-Perlit-Mikrostruktur mit Ausscheidungsstärkung durch Vanadium-, Niob- und Titankarbide sowie -nitrate auf. Dieses metallurgische Design bietet ein optimales Gleichgewicht zwischen Festigkeit, Zähigkeit und Schweißbarkeit.

Herstellungsprozess

MetalZenith produziert ASTM A572 Grade 50 mit fortschrittlicher Lichtbogenofen-Technologie, gefolgt von Pfannenverfeinerung und kontinuierlichem Gießen. Der Stahl wird im Bereich der Austenit-Rekristallisation und der nicht-rekristallisierten Temperaturen kontrolliert gewalzt, gefolgt von beschleunigter Abkühlung, um eine optimale Kornverfeinerung zu erreichen. Unser thermomechanisches Kontrollverfahren (TMCP) gewährleistet konsistente mechanische Eigenschaften und verbesserte Zähigkeit bei gleichzeitiger Beibehaltung hervorragender Schweißbarkeitseigenschaften.

Wärmebehandlungsoptionen

ASTM A572 Grade 50 wird typischerweise im gewalzten Zustand geliefert, was optimale mechanische Eigenschaften ohne zusätzliche Wärmebehandlung bietet. Für spezifische Anwendungen, die eine Spannungsfreigabe erfordern, kann der Stahl bei 580-650°C für 1-2 Stunden pro 25 mm Dicke wärmebehandelt werden. Normalisieren bei 900-950°C, gefolgt von Luftkühlung, kann durchgeführt werden, um die Kornstruktur zu verfeinern und die Zähigkeit für kritische Anwendungen zu verbessern.

Schweißeigenschaften

Der Stahl weist eine ausgezeichnete Schweißbarkeit mit allen gängigen Schweißverfahren, einschließlich SMAW, GMAW, FCAW und SAW, auf. Das niedrige Kohlenstoffäquivalent (CE ≤ 0.45) minimiert das Risiko von Kaltverzug und reduziert die Anforderungen an das Vorwärmen. Für Abschnitte, die dicker als 25 mm sind, wird ein Vorwärmen auf 100-150°C empfohlen. Eine Nachbehandlung nach dem Schweißen ist für die meisten strukturellen Anwendungen in der Regel nicht erforderlich.

Qualitätsstandards & Prüfung

MetalZenith führt umfassende Qualitätskontrollen während des gesamten Herstellungsprozesses durch, einschließlich der Überwachung der chemischen Zusammensetzung in Echtzeit, der Überprüfung der mechanischen Eigenschaften und der zerstörungsfreien Prüfung. Alle Produkte unterliegen einer Ultraschallprüfung, einer dimensionalen Inspektion und einer Bewertung der Oberflächenqualität. Unser Qualitätsmanagementsystem entspricht den Standards ISO 9001:2015, ISO 14001 und OHSAS 18001 und gewährleistet eine konsistente Produktqualität sowie vollständige Rückverfolgbarkeitsdokumentation.

🧪 Chemical Composition

| Element | Zusammensetzung (%) | Hinweise |

|---|---|---|

| Kohlenstoff (C) | ≤ 0.23 | Maximal |

| Mangan (Mn) | 1.35 max | Festigkeitssteigerung |

| Phosphor (P) | ≤ 0.030 | Maximal |

| Schwefel (S) | ≤ 0.030 | Maximal |

| Silizium (Si) | 0.40 max | Entgasungsmittel |

| Kupfer (Cu) | 0.35 max | Korrosionsbeständigkeit |

| Nickel (Ni) | 0.40 max | Zähigkeitserhöhung |

| Chrom (Cr) | 0.30 max | Härtbarkeit |

| Molybdän (Mo) | 0.15 max | Festigkeitssteigerung |

| Vanadium (V) | 0.10 max | Kornglättung |

| Niob (Nb) | 0.05 max | Ausscheidungsstärkung |

| Titan (Ti) | 0.15 max | Kornglättung |

⚙️ Mechanical Properties

| Eigenschaft | Wert | Testmethode |

|---|---|---|

| Streckgrenze (0,2% Versatz) | ≥ 345 MPa (50 ksi) | ASTM A370 |

| Zugfestigkeit | 450-590 MPa (65-85 ksi) | ASTM A370 |

| Dehnung in 200mm | ≥ 18% | ASTM A370 |

| Dehnung in 50mm | ≥ 21% | ASTM A370 |

| Brinell-Härte | 170-220 HB | ASTM E10 |

| Charpy V-Notch Schlag (20°C) | ≥ 27 J (20 ft-lb) | ASTM A370 |

| Charpy V-Notch Schlag (-40°C) | ≥ 20 J (15 ft-lb) | ASTM A370 |

| Ermüdungsgrenze (10&sup7; Zyklen) | 160-180 MPa | ASTM D7791 |

| Flächenreduktion | ≥ 50% | ASTM A370 |

| Youngs Modul | 200-210 GPa | ASTM E111 |

| Schubmodul | 80-85 GPa | ASTM E143 |

| Poisson-Zahl | 0.27-0.30 | ASTM E132 |

🔬 Physical Properties

| Eigenschaft | Wert | Temperatur |

|---|---|---|

| Dichte | 7.85 g/cm³ | 20°C |

| Schmelzpunkt | 1510-1540°C | - |

| Wärmeleitfähigkeit | 54 W/m·K | 20°C |

| Wärmeleitfähigkeit | 35 W/m·K | 500°C |

| Spezifische Wärmekapazität | 500 J/kg·K | 20°C |

| Wärmeausdehnungskoeffizient | 12×10-6/K | 20-100°C |

| Wärmeausdehnungskoeffizient | 14×10-6/K | 20-500°C |

| Elektrische Widerstandsfähigkeit | 0.16 µΩ·m | 20°C |

| Magnetische Permeabilität | Ferromagnetisch | 20°C |

| Curie-Temperatur | 770°C | - |

| Wärmediffusivität | 13.8 mm²/s | 20°C |

| Emissivität | 0.85-0.95 | Oxidierte Oberfläche |

📏 Product Specifications

| Spezifikation | Verfügbare Optionen | Standards |

|---|---|---|

| Produktformen | Platten, Bleche, Stangen, Träger, Kanäle, Winkel, Rohre | ASTM A572 |

| Plattendicke | 6-200mm (0.25-8 Zoll) | ASTM A572 |

| Blechdicke | 1.5-6mm (0.06-0.25 Zoll) | ASTM A572 |

| Stangendurchmesser | 10-300mm (0.4-12 Zoll) | ASTM A572 |

| Standardbreiten | 1000-3000mm (40-120 Zoll) | ASTM A6 |

| Standardlängen | 6000-12000mm (20-40 Fuß) | ASTM A6 |

| Oberflächenfinish | Warmgewalzt, Kaltgewalzt, Entzundert, Strahlgebläßt | ASTM A6 |

| Kantenzustand | Walzkante, Schnittkante, Geschnittene Kante | ASTM A6 |

| Dicken-Toleranz | ±0.3mm (±0.012 Zoll) | ASTM A6 |

| Breiten-Toleranz | ±3mm (±0.125 Zoll) | ASTM A6 |

| Längen-Toleranz | ±6mm (±0.25 Zoll) | ASTM A6 |

| Planheit | 5mm/m maximale Abweichung | ASTM A6 |

| Internationale Standards | ASTM A572, EN 10025-2 (S355), JIS G3106 (SM490) | Mehrere |

Lassen Sie uns Erfolg für Ihr Projekt schaffen

Professionelles Team, Premium-Produkte, Vollständiger Service - Ihr Projekterfolg ist unsere Mission

Our Advantages in Processing ASTM A572 Grad 50

Fortgeschrittene thermomechanische Verarbeitung

MetalZenith setzt modernste kontrollierte Walz- und beschleunigte Kühltechnologien ein, um eine optimale Kornverfeinerung und Ausscheidungsstärkung zu erreichen. Unsere proprietären Wärmebehandlungsprozesse gewährleisten konsistente mechanische Eigenschaften und verbesserte Zähigkeit, während sie hervorragende Schweißbarkeitseigenschaften beibehalten.

Umfassendes Qualitätskontrollsystem

Unser integriertes Qualitätsmanagementsystem verfügt über die Überwachung der chemischen Zusammensetzung in Echtzeit, automatisierte mechanische Prüfungen und fortschrittliche zerstörungsfreie Prüfmethoden. Jedes Produkt durchläuft strenge Inspektionsprotokolle, einschließlich Ultraschallprüfung, dimensionsmäßiger Überprüfung und Oberflächenqualitätsbewertung, um die Einhaltung internationaler Standards zu gewährleisten.

Flexible Anpassung & Globale Lieferung

MetalZenith bietet umfangreiche Anpassungsoptionen, einschließlich spezieller Abmessungen, Oberflächenbehandlungen und Änderungen der mechanischen Eigenschaften. Unser globales Vertriebsnetz und strategische Lagerstandorte gewährleisten eine schnelle Lieferung weltweit, während unser technisches Support-Team umfassende Ingenieurdienstleistungen für spezifische Anwendungsanforderungen bereitstellt.

IHR VERTRAUENwürdiger STAHL

HERSTELLUNGSPARTNER

Schnellanfrage

Branchen, die wir bedienen

Professionelle Stahl-Lösungen in wichtigen Branchen

Qualifikationen & Zertifizierungen