20 سنة من الخبرة | 1000+ شريك علامة تجارية | تخصيص كامل

لدينا 20 عامًا من الخبرة في الصناعة، وقد تعاوننا مع أكثر من 1000 علامة تجارية، وندعم أي احتياجات للتخصيص.

Technical Specifications

Product Overview

الخصائص المعدنية

EN45 هو فولاذ هيكلي متوسط الكربون مع بنية دقيقة تتكون بشكل أساسي من البيرلايت في الحالة المعالجة. يوفر محتوى الكربون المتحكم فيه قوة وصلابة ممتازة مع الحفاظ على قابلية كافية للتشكيل للتطبيقات الهيكلية. تعزز البنية الدقيقة التي تم تحقيقها من خلال الدرفلة المتحكم فيها كل من خصائص القوة والمتانة.

عملية المعالجة الحرارية

تستخدم MetalZenith عملية تطبيع متحكم فيها عند 850-900 درجة مئوية تليها تبريد بالهواء لتطوير البنية الدقيقة بشكل مثالي. للحصول على خصائص محسنة، يوفر التبريد من 820-860 درجة مئوية تليها معالجة حرارية عند 550-650 درجة مئوية توازنًا ممتازًا بين القوة والمتانة. يضمن التحكم الدقيق في درجة الحرارة خصائص ميكانيكية متسقة في جميع أنحاء مقطع المادة.

عملية التصنيع

تشمل عملية التصنيع المتقدمة لدينا صهر فرن القوس الكهربائي، وتنقية القالب للتحكم الدقيق في الكيمياء، وصب مستمر لتحسين التجانس. تضمن الدرفلة المتحكم فيها مع جداول تقليل محسّنة بنية حبيبية دقيقة وخصائص ميكانيكية محسنة. يتم التحكم بعناية في المعالجة الحرارية بعد الدرفلة لتحقيق الخصائص المستهدفة.

اختبار جودة الهيكل

يخضع EN45 لاختبارات شاملة بما في ذلك تقييم أداء اللحام باستخدام إجراءات قياسية، وتقييم قدرة التشكيل من خلال اختبارات الانحناء، واختبار قوة التعب تحت التحميل الدوري، وتقييم مقاومة التآكل الجوي. تضمن هذه الاختبارات المتخصصة الأداء الأمثل في التطبيقات الهيكلية حيث تكون الموثوقية حاسمة.

اعتبارات هندسة التطبيقات

في بناء المباني، يوفر EN45 قدرة تحمل ممتازة ومقاومة زلزالية. في هندسة الجسور، تضمن مقاومته للتعب وخصائصه المناخية المتانة على المدى الطويل. في تصنيع الآلات، يمكّن الجمع بين القوة وقابلية التشغيل من تصنيع مكونات معقدة. في بناء المركبات، يعمل نسبة القوة إلى الوزن على تحسين الكفاءة الهيكلية مع الحفاظ على معايير السلامة.

🧪 Chemical Composition

| العنصر | التكوين (%) |

|---|---|

| الكربون (C) | 0.42 - 0.50 |

| المنغنيز (Mn) | 0.50 - 0.80 |

| السيليكون (Si) | 0.10 - 0.40 |

| الفوسفور (P) | ≤ 0.035 |

| الكبريت (S) | ≤ 0.035 |

| الكروم (Cr) | 0.15 - 0.35 |

| النيكل (Ni) | ≤ 0.30 |

| الموليبدينوم (Mo) | ≤ 0.10 |

⚙️ Mechanical Properties

| الخاصية | القيمة |

|---|---|

| قوة العائد (ميغاباسكال) | ≥ 355 |

| قوة الشد (ميغاباسكال) | 630 - 780 |

| التمدد (%) | ≥ 16 |

| طاقة الصدمة عند 20°C (جول) | ≥ 35 |

| الصلابة (HB) | 180 - 230 |

| قوة التعب (ميغاباسكال) | 280 - 320 |

🔬 Physical Properties

| الخاصية | القيمة |

|---|---|

| الكثافة (غ/سم³) | 7.85 |

| نقطة الانصهار (°م) | 1460 - 1520 |

| الموصلية الحرارية (W/m·K) | 42.6 |

| التوسع الحراري (×10??/K) | 11.5 |

| معامل المرونة (GPa) | 210 |

| نسبة بواسون | 0.27 - 0.30 |

📏 Product Specifications

| المواصفات | التفاصيل |

|---|---|

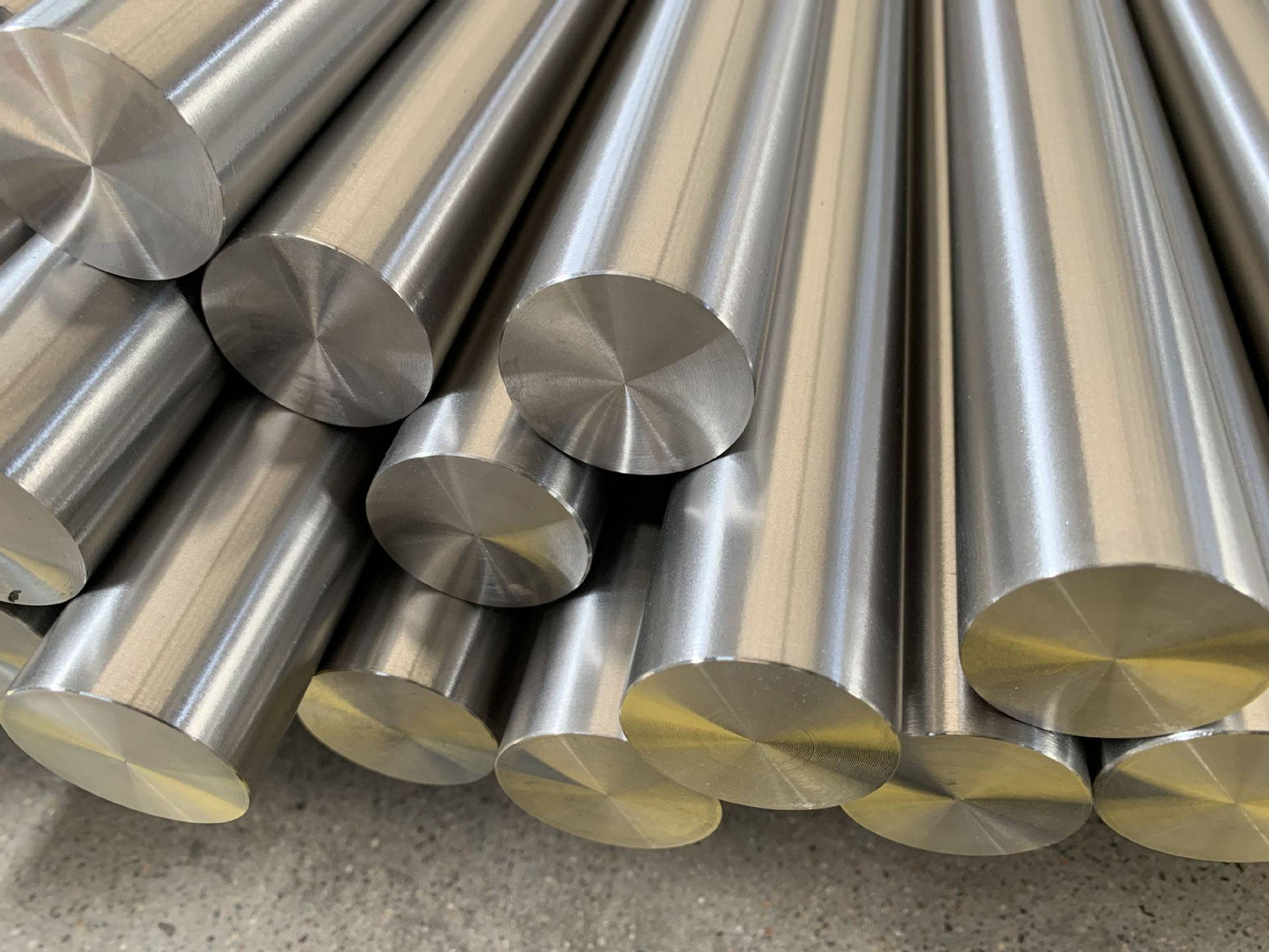

| الأشكال المتاحة | ألواح، صفائح، قضبان، عوارض، قنوات، زوايا |

| نطاق السماكة | 3 - 150 مم |

| نطاق العرض | 500 - 3000 مم |

| نطاق الطول | 3000 - 12000 مم |

| الامتثال للمعايير | EN 10083-2، ASTM A29، JIS G4051 |

| حالة المعالجة الحرارية | مُعالج، مُبرد ومُعالج حرارياً |

| تشطيب السطح | مدرفل على الساخن، مُسحوب على البارد، مُشغل |

دعونا نخلق النجاح لمشروعك

فريق محترف، منتجات متميزة، خدمة كاملة - نجاح مشروعك هو مهمتنا

Our Advantages in Processing EN45 فولاذ

معالجة الحرارة المتقدمة

تستخدم MetalZenith عمليات التبريد والتحليل الحراري المسيطر عليها مع مراقبة دقيقة لدرجات الحرارة لتحقيق توزيع مثالي للصلابة والقوة. تضمن معالجة الحرارة المتقدمة لدينا خصائص ميكانيكية متسقة في جميع أنحاء مقطع المادة، مما يعظم الأداء الهيكلي.

اختبار هيكلي شامل

يخضع فولاذ EN45 لدينا لاختبارات صارمة تشمل تقييم أداء اللحام، وتقييم قدرة التشكيل، واختبار قوة التعب، وتحليل مقاومة التآكل الجوي. تضمن هذه الاختبارات الشاملة الأداء الأمثل في التطبيقات الهيكلية.

خدمات التصنيع المخصصة

MetalZenith تقدم خدمات معالجة مخصصة كاملة بما في ذلك القطع، والتشغيل الآلي، والمعالجة الحرارية، والتشطيب السطحي. يقدم فريقنا الفني استشارات خبراء لتحسين تصميم الهياكل وإرشادات اختيار المواد.

موثوق بك الفولاذ

شريك التصنيع

استفسار سريع

الصناعات التي نقدم خدماتنا لها

حلول الصلب الاحترافية عبر الصناعات الرئيسية

المؤهلات والشهادات