20 Anos de Experiência | 1000+ Parceiros de Marca | Personalização Completa

Temos 20 anos de experiência na indústria, fizemos parceria com mais de 1.000 marcas e apoiamos quaisquer necessidades de personalização.

Technical Specifications

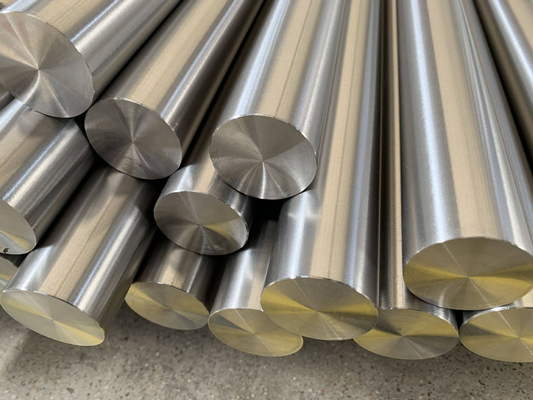

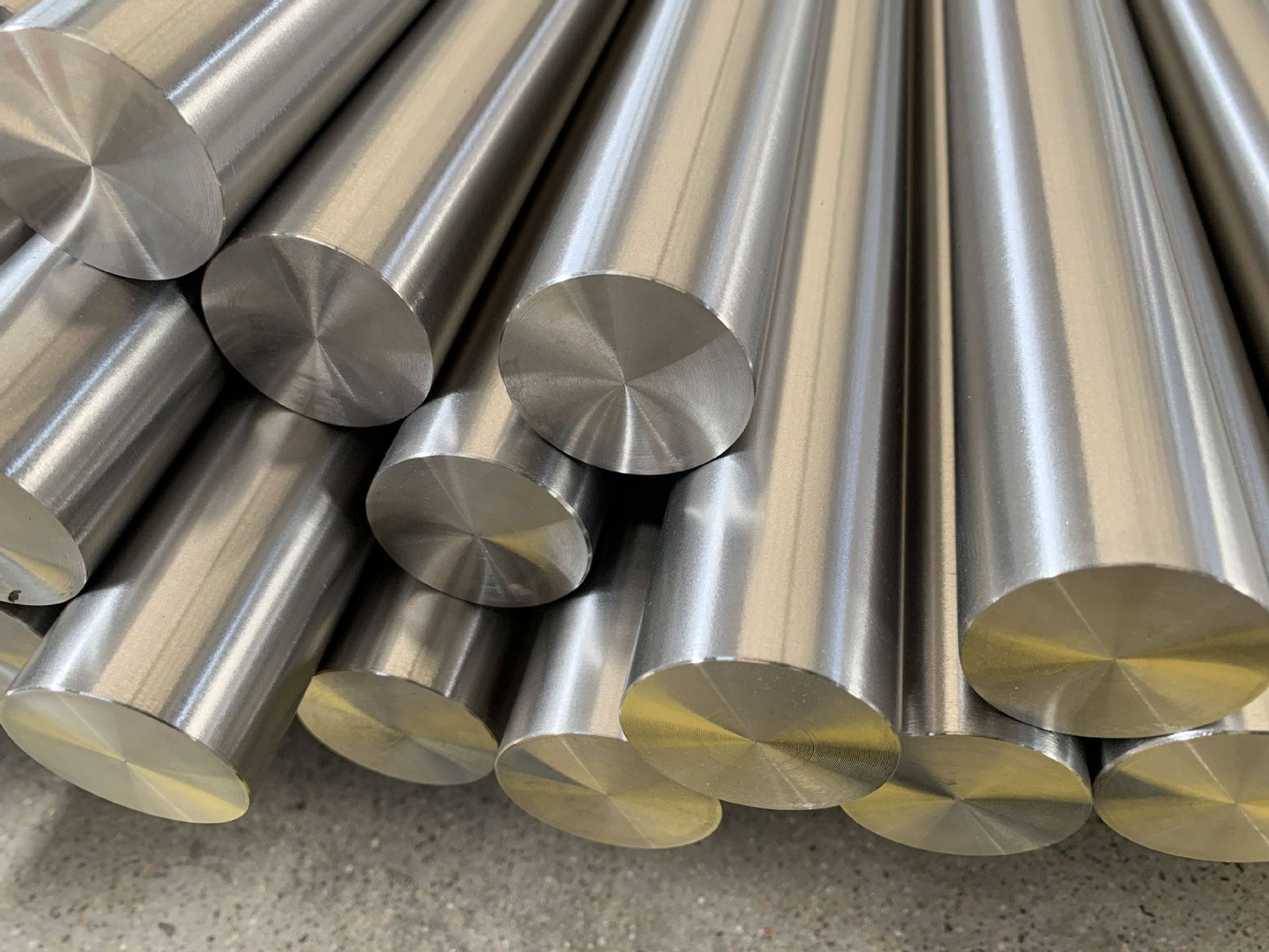

Product Overview

Características Metalúrgicas

O Aço Níquel exibe uma microestrutura totalmente austenítica com rede cristalina cúbica de face centrada, proporcionando excelente ductilidade e tenacidade. O aumento do teor de níquel estabiliza a fase austenítica e melhora a resistência à corrosão através da formação de uma camada passiva estável de óxido de cromo. A microestrutura permanece estável em uma ampla faixa de temperatura, garantindo desempenho consistente em condições operacionais variadas.

Processo de Tratamento Térmico

A MetalZenith emprega recozimento em solução a 1050-1100°C seguido de resfriamento rápido para alcançar propriedades microestruturais ótimas. Este processo dissolve carbonetos, alivia tensões internas e garante máxima resistência à corrosão. O tratamento de passivação pós-recozimento melhora a formação da camada de óxido protetora.

Processo de Fabricação Avançado

A MetalZenith utiliza fusão por indução a vácuo seguida de descarbonetação com argônio e oxigênio (AOD) para alcançar controle preciso da composição química e minimizar impurezas. Nossos processos controlados de laminação e recozimento garantem uma estrutura de grão uniforme e propriedades mecânicas ótimas em toda a seção transversal do material.

Testes de Qualidade Especializados

Os testes abrangentes incluem medição do potencial de pitting em solução de NaCl a 3,5%, testes de corrosão intergranular ASTM A262 Prática A, avaliação de trincas por corrosão sob tensão em solução de MgCl2 fervente e análise da espessura da camada de passivação usando espectroscopia de fotoelétrons de raios X. Testes adicionais incluem medição do teor de ferrita e análise do tamanho de grão para garantir propriedades microestruturais ótimas.

Considerações Específicas de Aplicação

Para aplicações em equipamentos químicos, atenção especial é dada à resistência à trinca por corrosão sob tensão por cloretos e resistência à oxidação em alta temperatura. Aplicações na indústria alimentícia exigem conformidade com as regulamentações da FDA e qualidade aprimorada do acabamento superficial. Aplicações em dispositivos médicos demandam testes de biocompatibilidade e controle dimensional preciso. Aplicações marinhas focam na resistência à corrosão em fendas e durabilidade a longo prazo em ambientes de água salgada. Aplicações arquitetônicas enfatizam acabamentos superficiais estéticos e resistência às intempéries.

🧪 Chemical Composition

| Elemento | Composição (%) |

|---|---|

| Carbono (C) | ≤ 0.08 |

| Cromo (Cr) | 17.0 - 20.0 |

| Níquel (Ni) | 8.0 - 12.0 |

| Manganês (Mn) | ≤ 2.0 |

| Silício (Si) | ≤ 1.0 |

| Fósforo (P) | ≤ 0.045 |

| Enxofre (S) | ≤ 0.030 |

| Nitrogênio (N) | ≤ 0.10 |

⚙️ Mechanical Properties

| Propriedade | Valor |

|---|---|

| Resistência ao Esforço (MPa) | ≥ 205 |

| Resistência à Tração (MPa) | 515 - 690 |

| Alongamento (%) | ≥ 40 |

| Dureza (HRB) | ≤ 92 |

| Taxa de Corrosão (mm/ano) | < 0.1 em água do mar |

| Potencial de Pitting (mV vs SCE) | > 350 |

🔬 Physical Properties

| Propriedade | Valor |

|---|---|

| Densidade (g/cm3) | 8.0 |

| Ponto de Fusão (°C) | 1400 - 1450 |

| Condutividade Térmica (W/m·K) | 16.2 |

| Expansão Térmica (×10??/K) | 17.3 |

| Resistividade Elétrica (μΩ·cm) | 72 |

| Módulo de Elasticidade (GPa) | 200 |

📏 Product Specifications

| Especificação | Detalhes |

|---|---|

| Formas Disponíveis | Placas, Folhas, Barras, Tubos, Conexões, Forjados |

| Faixa de Espessura | 0,5 - 80mm |

| Faixa de Largura | 1000 - 2500mm |

| Faixa de Comprimento | 2000 - 12000mm |

| Conformidade com Normas | ASTM A240, AISI 304, EN 1.4301, JIS SUS304 |

| Acabamento de Superfície | 2B, BA, No.4, HL, Espelho |

| Condição de Tratamento Térmico | Solubilizado |

Vamos Criar Sucesso para o Seu Projeto

Equipe Profissional, Produtos Premium, Serviço Completo - O Sucesso do Seu Projeto é Nossa Missão

Our Advantages in Processing Aço Níquel

Tecnologia Avançada de Fusão a Vácuo

MetalZenith utiliza fusão por indução a vácuo de última geração e processamento em atmosfera controlada para alcançar uma distribuição ideal de níquel e minimizar impurezas. Nossa solução de recozimento de precisão a 1050-1100°C garante a formação completa da estrutura austenítica e máxima resistência à corrosão.

Teste de Corrosão Abrangente

MetalZenith realiza testes extensivos de corrosão, incluindo medição do potencial de pite (>350mV vs SCE), testes de corrosão intergranular ASTM A262, avaliação de fissuração por corrosão sob tensão em ambientes de cloreto e análise da espessura da camada de passivação usando tecnologia XPS para garantir desempenho superior.

Processamento Personalizado e Suporte Técnico

MetalZenith oferece serviços abrangentes de processamento personalizado, incluindo usinagem de precisão, acabamento de superfície e tratamentos térmicos especializados. Nossa equipe técnica fornece consultoria especializada para requisitos específicos de aplicação e otimização da seleção de materiais.

SEU CONFIÁVEL AÇO

PARCEIRO DE MANUFATURA

Quick Inquiry

Indústrias que Atendemos

Soluções de aço profissionais em grandes indústrias

Qualificações e Certificações