20 Anos de Experiência | 1000+ Parceiros de Marca | Personalização Completa

Temos 20 anos de experiência na indústria, fizemos parceria com mais de 1.000 marcas e apoiamos quaisquer necessidades de personalização.

Technical Specifications

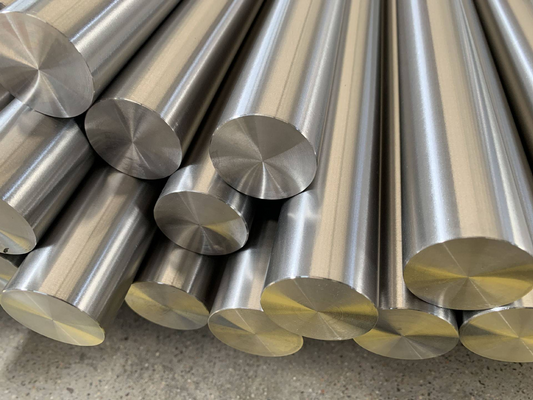

Product Overview

Características Metalúrgicas

JIS SUJ2 é um aço de alto carbono e baixa liga, especificamente projetado para aplicações de rolamentos. A microestrutura do aço consiste em perlita fina na condição de recozimento, que se transforma em martensita com austenita retida durante a têmpera. O teor de cromo proporciona maior endurecibilidade e resistência ao desgaste, mantendo excelente estabilidade dimensional durante o tratamento térmico.

Processo de Tratamento Térmico

O processo de tratamento térmico controlado da MetalZenith envolve austenitização a 820-860°C, seguido de resfriamento em óleo para alcançar a dureza total. O revenimento é realizado a 150-200°C para atingir a faixa de dureza desejada de 60-65 HRC. Nossa tecnologia avançada de fornos garante aquecimento uniforme e controle preciso da temperatura durante todo o processo, resultando em propriedades mecânicas consistentes e mínima distorção.

Excelência no Processo de Fabricação

Nosso processo de produção começa com a fusão em forno de arco elétrico, seguido de refino em panela e desgasificação a vácuo para alcançar um conteúdo de inclusão ultra-baixo. O aço é fundido em lingotes ou bilhetes fundidos continuamente, e depois laminado a quente nas dimensões necessárias. Operações de trefilação a frio e retificação de precisão estão disponíveis para alcançar tolerâncias dimensionais apertadas e acabamento superficial superior.

Padrões de Qualidade & Testes

A MetalZenith mantém estrita adesão aos padrões JIS G 4805 e implementa protocolos abrangentes de controle de qualidade. Cada lote passa por uma análise química completa, testes mecânicos, inspeção ultrassônica e testes de partículas magnéticas. Nosso sistema de gestão da qualidade certificado ISO 9001:2015 garante qualidade consistente do produto e total rastreabilidade desde as matérias-primas até os produtos acabados. Serviços adicionais de teste incluem testes de fadiga, avaliação de limpeza e análise microestrutural para atender a requisitos específicos dos clientes.

🧪 Chemical Composition

| Elemento | Composição (%) |

|---|---|

| Carbono (C) | 0.95 - 1.10 |

| Silício (Si) | 0.15 - 0.35 |

| Manganês (Mn) | ≤ 0.50 |

| Fósforo (P) | ≤ 0.025 |

| Enxofre (S) | ≤ 0.025 |

| Cromo (Cr) | 1.30 - 1.60 |

| Níquel (Ni) | ≤ 0.25 |

| Cobre (Cu) | ≤ 0.25 |

| Alumínio (Al) | ≤ 0.050 |

| Oxigênio (O) | ≤ 0.0015 |

⚙️ Mechanical Properties

| Propriedade | Valor | Condição |

|---|---|---|

| Resistência à Tração | 2100 - 2400 MPa | Endurecido & Temperado |

| Resistência de Escoamento | 1800 - 2100 MPa | Endurecido & Temperado |

| Alongamento | 8 - 12% | Endurecido & Temperado |

| Dureza (HRC) | 60 - 65 | Endurecido & Temperado |

| Dureza (HB) | ≤ 269 | Recozido |

| Energia de Impacto (Charpy V) | 15 - 25 J | Temperatura Ambiente |

| Limite de Fadiga | 900 - 1100 MPa | 107 ciclos |

| Módulo de Young | 210 GPa | Temperatura Ambiente |

| Razão de Poisson | 0.27 - 0.30 | Temperatura Ambiente |

🔬 Physical Properties

| Propriedade | Valor | Temperatura |

|---|---|---|

| Densidade | 7.81 g/cm³ | 20°C |

| Ponto de Fusão | 1480 - 1520°C | - |

| Condutividade Térmica | 42.6 W/m·K | 20°C |

| Coeficiente de Expansão Térmica | 12.3×10-6/K | 20-100°C |

| Capacidade Calorífica Específica | 460 J/kg·K | 20°C |

| Resistividade Elétrica | 0.25 µΩ·m | 20°C |

| Permeabilidade Magnética | Ferromagnético | Temperatura Ambiente |

| Temperatura de Curie | 740°C | - |

| Difusividade Térmica | 11.8 mm²/s | 20°C |

📏 Product Specifications

| Especificação | Opções Disponíveis | Normas |

|---|---|---|

| Formas de Produto | Barras Redondas, Barras Quadradas, Barras Planas, Vergalhões, Anéis Forjados | JIS G 4805 |

| Diâmetro da Barra Redonda | 6mm - 300mm | JIS G 4805 |

| Tamanho da Barra Quadrada | 10mm - 150mm | JIS G 4805 |

| Espessura da Barra Plana | 5mm - 100mm | JIS G 4805 |

| Diâmetro do Vergalhão | 5.5mm - 42mm | JIS G 3507 |

| Comprimento | 3000mm - 12000mm (Comprimentos personalizados disponíveis) | Especificação do Cliente |

| Acabamento de Superfície | Laminado a Quente, Laminado a Frio, Descascado, Moído | JIS G 4805 |

| Tolerância Dimensional | h9, h10, h11 (ISO 286) | ISO 286-2 |

| Condição de Tratamento Térmico | Recozido, Normalizado, Esferoidizado | JIS G 4805 |

| Normas Equivalentes | AISI 52100, EN 100Cr6, DIN 1.3505 | Internacional |

Vamos Criar Sucesso para o Seu Projeto

Equipe Profissional, Produtos Premium, Serviço Completo - O Sucesso do Seu Projeto é Nossa Missão

Our Advantages in Processing JIS SUJ2

Tecnologia Avançada de Desgaseificação a Vácuo

MetalZenith emprega processos de desgasificação a vácuo e refino em panela de ponta para alcançar um conteúdo de inclusão ultra-baixo e uma limpeza superior do aço. Nossa fusão em atmosfera controlada garante uma vida útil excepcional de fadiga de rolamentos e confiabilidade em aplicações críticas.

Sistema Abrangente de Controle de Qualidade

Nossa instalação certificada pela ISO 9001:2015 possui capacidades avançadas de teste, incluindo inspeção ultrassônica, teste de partículas magnéticas e análise química completa. Cada lote passa por testes mecânicos rigorosos para garantir desempenho consistente e conformidade com os padrões JIS G 4805.

Cadeia de Suprimentos Global e Soluções Personalizadas

MetalZenith oferece soluções de fornecimento flexíveis com capacidades de distribuição global e serviços de processamento personalizados. Fornecemos tratamento térmico sob medida, usinagem de precisão e tratamentos de superfície especializados para atender a requisitos específicos dos clientes e cronogramas de entrega.

SEU CONFIÁVEL AÇO

PARCEIRO DE MANUFATURA

Quick Inquiry

Indústrias que Atendemos

Soluções de aço profissionais em grandes indústrias

Qualificações e Certificações